In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: August 12, 2025

Techtextil India Announces Strategic Tie-up for Launching ‘ReCycle Zone’

In a push to advance circularity and environmental accountability in the technical textiles sector, Techtextil India 2025 will launch the dedicated ‘ReCycle Zone’ in collaboration with the Society of Plastics Engineers India (SPE India). Reclaim, Reuse and Reimagine are among the key features of the zone at the upcoming edition of Techtextil India scheduled from 19th – 21st November 2025 at the Bombay Exhibition Centre, Mumbai.

As industries across the globe adopt circular economy models and sustainable production practices, the ReCycle Zone will serve as a vital platform for stakeholders working to transform textile and plastic waste into value-added materials. The initiative reflects Technical India’s ongoing commitment to driving responsible innovation by converging recyclers, solution providers, machinery manufacturers startups and policy enablers under one roof. This new industry focused zone will spotlight sustainable innovation and next-gen recycling technologies.

The ReCycle Zone will host companies specializing in:

- Garment, agro-textiles and medical textiles waste recycling

- Plastic and PET waste recycling for textile applications

- Fiber to fiber and yarn regeneration

- Sorting, shredding and advanced recycling machinery

- EPR compliance, traceability and green certifications

- AI and automation in waste management systems

This initiative aims to bridge the gap between innovation and implementation by connecting buyers, suppliers, R&D specialists and sustainability officers.

KARL MAYER Technical Textiles Names Hagen Lotzmann Managing Director

KARL MAYER Technical Textiles has had a new managing director since July 1. Hagen Lotzmann – a manager and expert from within the company’s own ranks – has taken over the position at the head of the company and, at the same time, the role of president of the KARL MAYER Technical Textiles business unit.

The mechanical engineer has been contributing to the success of KARL MAYER Technical Textiles in various fields since 2008 and has learned the company’s business from the ground up. He earned his first credentials as a development engineer in application technology and later became the primary point of contact for customers as a sales engineer.

In 2013, Lotzmann moved into sales management and went on to head the Sales, Product Management and Application Technology departments.

This gives Lotzmann a solid foundation on which to build in his role as managing director. His new responsibilities are demanding: the sites in Chemnitz and Selbitz will be set up as strong locations for service, sales, and development. The production and assembly of the machines will be relocated within the KARL MAYER Group.

Kimberly-Clark Appoints John Carmichael as President, North America

Kimberly-Clark Corporation announced the appointment of John Carmichael as President, North America, effective September 15th. Carmichael succeeds interim President Kurt Laufer, who will resume his prior role as President of U.S. Consumer Sales.

As President, North America, Carmichael will lead Kimberly-Clark’s personal care, family care, and professional businesses across the United States and Canada. He will report to Russ Torres, President and Chief Operating Officer of Kimberly-Clark.

Carmichael joins Kimberly-Clark after three decades at Nestlé, most recently serving as President and CEO of Nestlé Canada, where he oversaw a broad portfolio that included ice cream, coffee, beverages, water, confectionery, nutrition and pet care. Under his leadership, Nestlé Canada delivered consistent growth and built a purpose-driven culture rooted in innovation, community impact and operational excellence.

Prior to that role, Carmichael held several senior leadership positions at Nestlé USA, including President of the Foods Division, President of the Beverage Division, and Vice President of Sales and Customer Development. Throughout his career, he has played a pivotal role in repositioning brands for growth, leading business turnarounds, driving strategic acquisitions, and scaling emerging businesses and platforms.

Carmichael holds a Bachelor of Arts in Political Science from UCLA and an MBA in Marketing and Entrepreneurship from the UCLA Anderson School of Management.

American Textile Company’s Reid W. Ruttenberg Passes

Reid W. Ruttenberg, who steered family-owned American Textile Company from a regional manufacturer to a global utility bedding supplier, passed away peacefully on Aug. 7. He was 89.

Ruttenberg was the second generation to lead the business that had was founded in 1925 by his father and four uncles. During his life, he held numerous leadership roles, becoming President in 1964 and Chairman of the Board in 1991. From 2000 until his passing, he remained an active member of the board.

Ruttenberg was a lifelong Pittsburgher who never lived more than a mile from where he was born. Nonetheless, he had an expansive vision for the family business. Under his leadership, American Textile Company became one of the largest basic bedding companies in the United States and expanded its reach to more than 20 countries. Today, its products are carried in more than 40,000 stores and online retailers worldwide.

Carbon-Fiber Recycling Innovation Wins Funding

Cleantech company Uplift360 has been awarded an Innovate UK Smart Grant to scale its pioneering low-energy chemical recycling technology, ChemR. Selected as one of only 44 successful projects from a pool of 2,134 applications, ChemR is the world’s first ambient-condition chemical recycling process for advanced composite materials. It has the potential to transform carbon fiber waste management across aerospace, automotive, defense, and clean energy sectors.

The use of Carbon Fibre Reinforced Polymers (CFRPs) is rapidly expanding due to their high strength, low weight, and corrosion resistance. Yet as much as 50% of CFRP is wasted during manufacturing, and the UK currently produces between 30,000–50,000 tonnes of CFRP waste annually — material with a potential value exceeding £1.2 billion if effectively recycled. With only 20% of CFRP waste currently recycled — and less than 2% reused due to limitations in thermal and mechanical recycling methods — the sector urgently needs a scalable, sustainable alternative.

Navis TubeTex Partners with Mascoe Systems

Navis TubeTex, a global leader in dyeing and finishing machinery and technology for the textile industry, announced a strategic partnership with Mascoe Systems to manufacture, sell, and service Mascoe’s line of coaters across the industrial, upholstery, and apparel markets. This powerful alliance marks a major step forward in expanding Navis TubeTex’s already extensive portfolio of advanced coating technologies.

Mascoe Systems, a respected and trusted brand in the coating industry, brings decades of proven innovation and performance to the table. Through this partnership, the well-known Mascoe coater designs will now be backed by the global reach, manufacturing excellence, and customer service strength of Navis TubeTex.

Navis TubeTex has built a strong reputation for engineering excellence, offering customers customized solutions in foam application, rotary spray, dry impregnation, slot-die, knife-over-roll, gravure, and other coating technologies. The addition of the Mascoe product line adds yet another dimension to the company’s offering, reinforcing its position as the most progressive and comprehensive provider of coating equipment in the industry.

Joe Poterala, owner of Mascoe Systems, will continue to work closely with Navis TubeTex, lending his expertise to ensure product continuity, innovation, and exceptional customer support. “I’m excited to see the Mascoe line continue to grow under the leadership of Navis TubeTex,” said Poterala. “Their commitment to innovation and customer service makes them the ideal partner to take this technology to the next level.”

With this partnership, Navis TubeTex once again demonstrates its forward-thinking approach and dedication to delivering best-in-class solutions that help customers compete in today’s demanding global marketplace.

ExxonMobil Signature Polymers, TRAPO to Improve Car Mat Performance

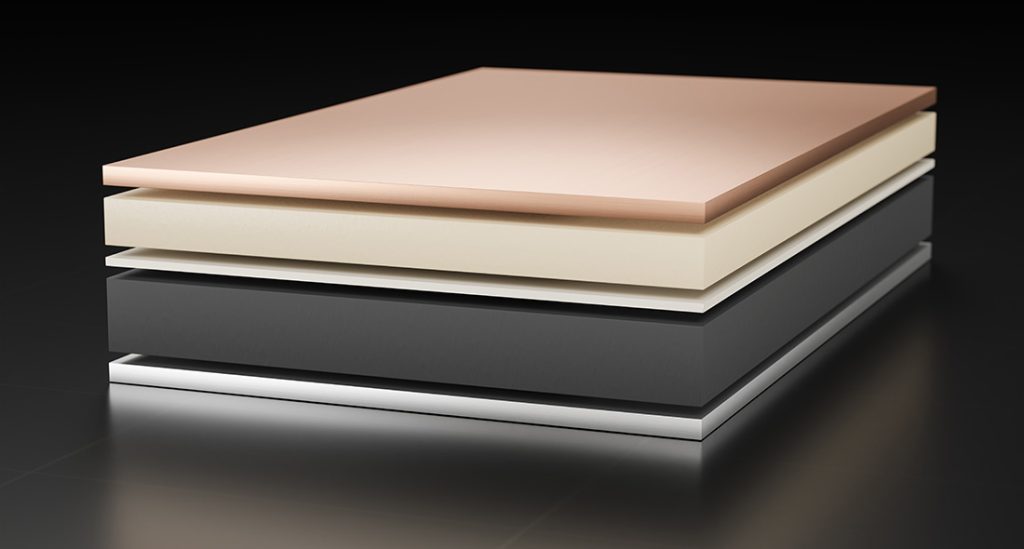

By adding Vistamaxx™ 6102 to its EVA (ethylene vinyl acetate) formulations, TRAPO – a leading automotive accessories brand in Asia, is able to create a new generation of car mat series. The new

Classic Mark IV mat displayed softer and better cushioning with improved anti-slip properties as compared to the current Classic Mark III mat.

The TRAPO Classic car mat series has used hook and loop fasteners at the back of its car mats

to provide an anti-slip feature. However, hook and loop fasteners can cause damage to car floorboards. Therefore, TRAPO sought to formulate a new series of mats that can help reduce or eliminate hook and loop fastener usage to avoid this problem while providing good anti-slip performance.

ExxonMobil introduced Vistamaxx™ performance polymers to TRAPO for their new car mat formulation and with a few trials, gave birth to TRAPO new Classic Mark IV mats. TRAPO R&D leveraged Vistamaxx™ performance polymers to help design the new Classic Mark IV mat, which makes it possible to recycle* the whole mat. There is also no need for any separation of the layers before recycling. This will potentially reduce wastage, increase productivity and enable TRAPO to initiate a recycling program to collect these car mats when they have reached their end of lifecycle. TRAPO aims to repurpose them back to the formulation to produce new products / new car mats for the consumer.

Toyota Tsusho and Asahi Kasei Form Supply Chain Partnership in North America

Toyota Tsusho America, Inc. (TAI) and diversified global manufacturer Asahi Kasei Battery Separator America, LLC (AKBSA) have established a strategic relationship for the supply of automotive lithium-ion battery (LIB) separators in North America. TAI and AKBSA have finalized a capacity rights agreement for AKBSA to supply Hipore™ wet-process LIB separators to TAI.

The agreement entitles TAI to a preferential share of AKBSA’s production capacity for Hipore™ LIB separators. Beginning in mid-2027, AKBSA will supply TAI with coated Hipore™ separators from its new coating facility currently under construction in Charlotte, North Carolina.

TAI will benefit from a stable supply of LIB separators manufactured at the Charlotte plant as it promotes the establishment of a highly stable automotive battery supply chain in North America. In addition, this arrangement allows AKBSA to mitigate the risk of market fluctuations and effectively utilize resources by maintaining high rates of operation.

By leveraging TAI’s global network and expertise in mobility with AKBSA’s strengths in functional materials, the new relationship will accelerate the adoption of high-quality wet-process separators in the North American battery market and facilitate the manufacture of higher-performance electric vehicles.

Loop Industries Announces Launch of Twist

Loop Industries, Inc., a clean technology company accelerating circularity in plastic and fiber markets, announced the launch of Twist™, a branded circular polyester resin made entirely from textile waste. Loop is currently advancing its discussions with apparel brands for offtake from its planned India JV and will supply Twist™ as its branded product offering. Originally developed as Loop’s fiber-grade PET resin, the product has now been rebranded to reflect its role in helping the textile industry transition from linear to circular systems, shifting away from virgin materials and from bottle-to-textile recycling, to give global brands a high-performance solution that embodies both sustainability and next-gen material innovation.

Utilizing Loop’s globally patented depolymerization technology, Twist™ is produced by breaking down polyester textile waste into its base monomers, DMT and MEG, which are then purified back to their initial purity, before being polymerized into Twist™ resin. This process removes all dyes, colorants, contaminants, and blends, delivering a resin that is chemically identical to virgin polyester. Textile-to-textile recycling allows apparel companies to mitigate the increasing environment impact of textile waste.

Twist™ achieves the highest purity, color and dyability consistency and increases production efficiency, making it fully compatible with existing spinning and manufacturing infrastructure.

The production of Twist™ saves up to 418,600 tonnes of CO₂ emissions annually and reduces greenhouse gas (GHG) emissions by up to 81% when compared to fossil fuel-based resin. This has been independently validated by Franklin Associates, a division of ERG who completed an LCA study of Loop’s technology. 418,600 tonnes of CO₂ emissions are the equivalent of more than 1 billion miles driven by an average gasoline-powered passenger vehicle.