Paul T. O’Day, president & counsel American Fiber Manufacturers Association passed away

The American Fiber Manufacturers Association (AFMA) is saddened to announce that long-time President Paul T. O’Day passed away on June 1st, 2017. “This is a very difficult day for the …

CORDURA brand and DuPont Tate & Lyle bio products shape the future of sustainable textiles

INVISTA’s CORDURA® brand and DuPont Tate & Lyle Bio Products announced a collaboration early in March 2017 to deliver a new chapter in innovative sustainable textile solutions for performance fabrics. …

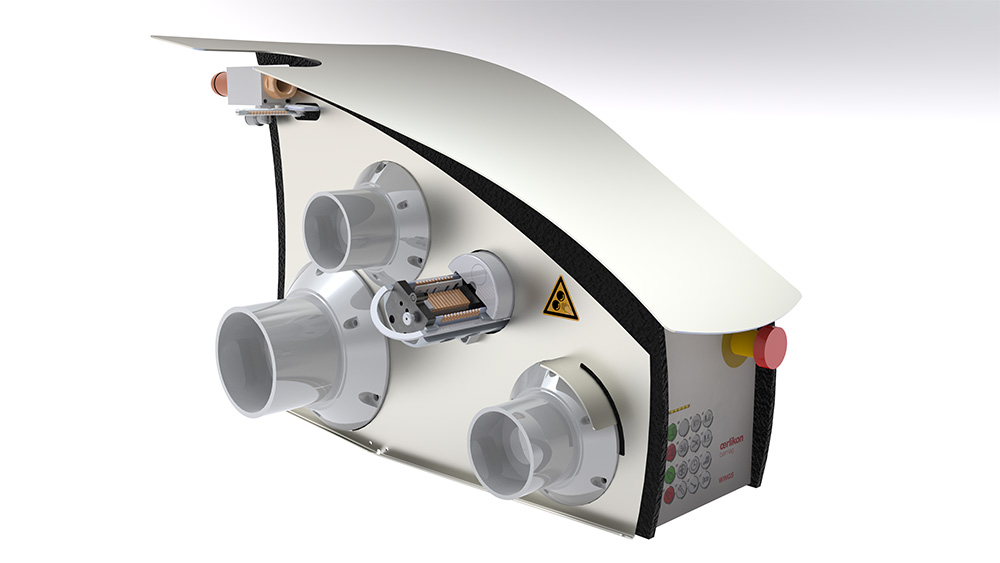

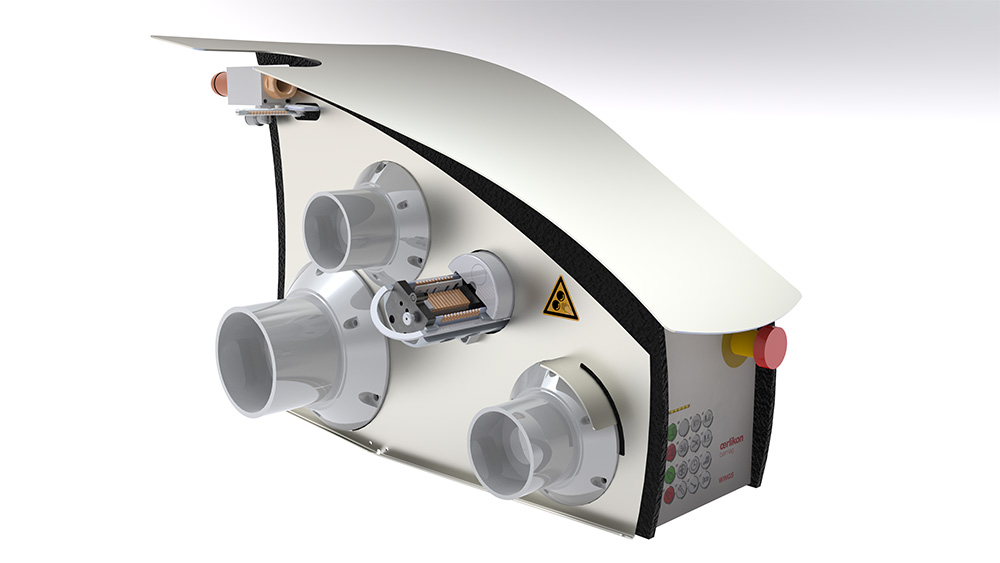

WINGS 1800 – high-speed winding concept for all relevant POY production windows

The now 10-year success story of the WINGS concept continues unabated. Oerlikon Barmag revolutionized the conventional filament yarn spinning system with the idea of integrating the draw unit into the winder itself. The fact that the WINGS family is meanwhile available for all market-relevant textile processes proves its everyday usability.

Unifi, Inc., brings home gold at World Textile Awards

World Textile Awards announced in February 2017 Unifi, Inc. as its 2016 Fiber Producer of the Year, highlighting the company’s outstanding product lineup. Unifi is a leader in producing high-quality …

Price Hanna with new report on global outlook for hygiene absorbent products

Price Hanna Consultants of the United States has recently published a February 2017 report on the world outlook for hygiene absorbent products and the key raw materials of nonwovens, fluff …