A consortium of five Egyptian researchers have developed the world’s first high-performance fibers and reinforcements extracted from the byproducts of pruning of date palms, such as frond and fruit stalks, also known as PalmFil. The fiber is not only sustainable, but also economical in manufacturing, compatible with textile and composite processing and offers the properties needed for lightweight cars of the future, according to the consortium.

“In the 1980’s the shift from natural fibers to manmade fibers was mainly to bridge the gap between the increasing demand for textile fibers and the limited supply of natural fibers,” said Mohamad Midani, Ph.D., a partner in the PalmFil Consortium. “In order to reverse this shift, there is a need to explore more sources of natural fibers and increase the biodiversity of fiber crops.

This is actually what we did. There are more than 140 million date palms mostly concentrated in the Middle East and North Africa, generating yearly more than 4.8 million tons (dry wt.) byproducts of pruning regarded as agriculture waste. This represented a burden on palm growers, and was the main cause of fire accidents and infestation by dangerous insects. Those byproducts could otherwise be transformed into 1.3 million tons/year natural textile fibers, ranking third after cotton and jute.”

“In the 1980’s the shift from natural fibers to manmade fibers was mainly to bridge the gap between the increasing demand for textile fibers and the limited supply of natural fibers,” said Mohamad Midani, Ph.D., a partner in the PalmFil Consortium. “In order to reverse this shift, there is a need to explore more sources of natural fibers and increase the biodiversity of fiber crops.”

PamFil is very versatile and available in many forms, including, long fiber tows, chopped fibers, spun yarns/rovings, nonwoven mats, woven fabrics, unidirectional tapes, pre-impregnated, comingled and finely milled fibers. The unique features and characteristics of PalmFil make it an excellent sustainable material base for a wide spectrum of industries. Ranging from natural reinforcements for composites in automotive and sporting goods, plaster reinforcements in construction, burlap sacks for packaging, ropes, and twines, non-wood papers, and other consumer products.

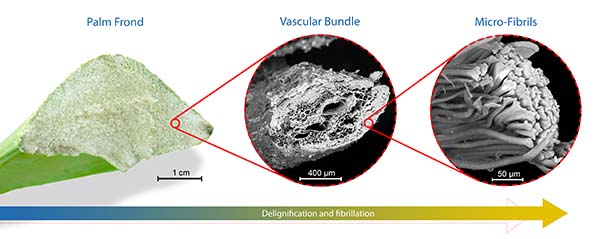

PalmFil is based on a proprietary extraction technology which delignifies and fibrillates the rigid fiber vascular bundles in the palm byprodcuts and eliminates the hollow lumens without causing any damage or breakage to the fibrils. Resulting in long, pure and flexible textile fibers, which is totally different from previous attempts to extract fibers from date palm byproducts through crushing and grinding.

PalmFil is also compatible with existing spinning and weaving technologies of hard vegetable fibers and it bonds well with polymer matrix, thanks to its protruding side fibrils that create mechanical interlocks in a composite matrix. Moreover, PalmFil extraction technology could be applied to byproducts of other palm species such as oil palm, sugar palm, doum palm as well as other agriculture byproducts such as broomcorn.

PalmFil contributes to the circular bioeconomy following a closed-loop cycle from cradle to cradle.

Key attributes

- Sustainable – PalmFil is obtained from renewable bioresources and it does not cause deforestation or compete with food production. It is 100% biodegradable and compostable, and has the ability to naturally degrade into its basic constituents and return back into the environment. PalmFil is carbon dioxide neutral.

- Abundant – Date palm is the main element of flora in the MENA region, with very high populations in Saudi Arabia, Iran, UAE, Iraq, Egypt and Algeria. Their estimated global population is 140 mil palms, generating 4.8 mil tons/year byproducts of pruning. The estimated fiber availability from those byproducts is 1.3 million tons/year, ranking third after cotton and jute. Palm pruning is performed year round, hence consistent supply with no seasonality issues.

- Economical – Palmfil is obtained from palm byproducts, and does not require extra investment in water, fertilizer, pesticide or land. Those byproducts are often regarded as agriculture waste, with zero price in field. The valorization of these byproducts can provide extra source of income to palm growers, and can generate thousands of decent jobs. In addition, it can create an entire value chain within rural communities.

- Strong – PalmFil specific tensile strength is five times higher than structural steel, and equal to those of flax, hemp and sisal. Its vibration damping and acoustical insulation is higher than those of glass and carbon and with thermal insulation higher than carbon. PalmFil has cellulose purity up to 70% and thermal stability up to 226 C.

- Lightweight and safe – PalmFil is 50% lighter than glass fiber, and 8% lighter than flax and hemp. It is safe for working health and does not require special personal protective equipment while handling. It also does not erode machine parts