The challenge will be to achieve a balance between ongoing capacity expansion and rising demand

The global fiber industry is facing unprecedented sustainability challenges. Issues such as a rising population, climate change, water scarcity, land use (food vs. fiber), deforestation and loss of biodiversity, plastic waste and marine pollution have combined to question the long-term credentials of the industry and its attempts to create a sustainable circular economy.

With production having tripled since 2000, fibers derived from natural cellulose – a non-petrochemical source – are gaining interest, according to UK-based analysts and consultants Tecnon OrbiChem.

And with annual demand currently at six million tonnes – mostly in staple, with filament declining – cellulose fibers are growing faster than mature fibers such as acrylic or polyamide, especially because of their softness, water absorption properties and cotton-like attributes.

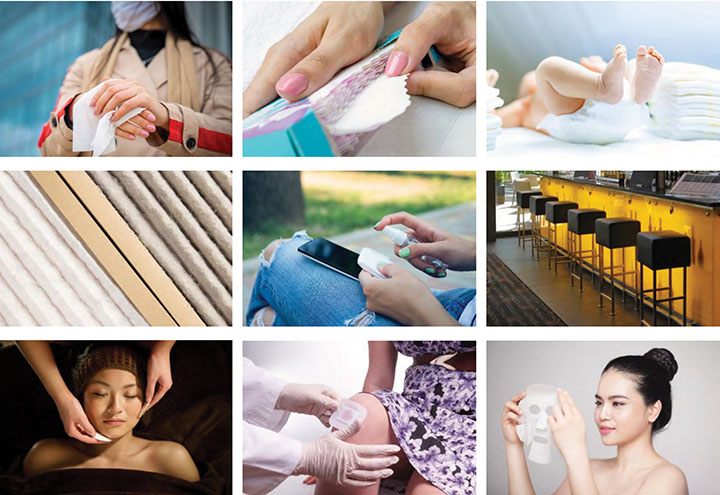

The heightened interest in cellulose fibers in recent years has given rise to an increasingly wide range of applications. They are perhaps the fastest growing textile fiber group and one of the largest investment sectors in the global bioeconomy.

International markets for these fibers are being driven by technological developments and a changing political framework, especially restrictions on single-use plastics and increasing sustainability requirements, in addition to the growing demand for alternatives to fossil-based fibers and bottlenecks in cotton production.

Supply/demand challenge

The challenge, however, will be to achieve a balance between the ongoing capacity expansion and rising demand for cellulose fibers, especially from the major brands, to avoid overcapacity in the future.

Addressing these key issues, the 3rd International Conference on Cellulose Fibres, held in February in Cologne, Germany, attracted around 230 delegates from 27 countries, of which more than 160 attended via the online platform.

Organized by Nova-Institut, the two-day event highlighted the latest innovations in the sector, including textiles, absorbent hygiene materials, carbon fiber alternatives and lightweight construction applications.

With over 40 speakers, the conference focused on opportunities for cellulose fibers through information on policy assessment, sustainability, recycling and alternative feedstocks, as well as the latest developments in pulp, cellulose fibers and yarns, including applications such as nonwovens, packaging and composites.

Strategies and market trends

The opening session provided an overview of the rapid development of cellulose fibers and their technological progress across the fiber market. It included an analysis of the key cost components of these fibers to benchmark against current cost levels, highlighting future opportunities and challenges for novel textile fibers, and concluded with an overview of the industry’s recent strategies to defossilize the fiber market.

Professor Ali Harlin, VTT Technical Research Centre of Finland, noted that several innovative technologies are now in the pilot and demonstration phases in Finland, with the first factory projects now active. These include Metsä Spring’s Kuura fiber, Infinited Fiber’s Infinna fiber and Spinnova’s Spinnova fiber.

Assessing future opportunities and challenges for novel textile fibers, speakers from AFRY Management Consulting, Finland, said that in future such materials will need to be both cost- and quality-competitive with mainstream textile fibers.

Noting that demand for textiles has more than doubled over the past 30 years, principally driven by the rise in global population and the growth of the middle classes, they added that there are now more environmentally conscious consumers demanding industry change.

However, alternative feedstocks will need to complement existing solutions, initially at least, and there will be an increasing emphasis on traceability in the supply chain.

Novel textile fibers will also need to overcome numerous barriers to commercialization. Securing feedstocks and further development of technologies will be essential, AFRY concluded.

New opportunities

The session on new opportunities for cellulose fibers in replacing plastics focused on such issues as the ban on plastics in single-use products and the latest regulatory issues and policy prospects for cellulose fibers.

This session presented opportunities for the replacement of fossil-based insulating materials with cellulose-based technologies suitable for use in a range of applications, from aerospace to mobility and construction.

Dr. Sascha Schriever of the Institute of Textile Technology, RWTH Aachen University, Germany, discussed the development of cellulose aerogel nonwovens, which are particularly suitable as lightweight insulation materials owing to their acoustic and thermal properties.

Such materials also have potential as a catalyst carrier, in filter technology (e.g., hollow fiber filters) and carbonized for electrodes and catalysts.

Sustainability and circular economy

The session on sustainability and circular economy highlighted crucial issues with regard to the overall goal of keeping the environmental impact of cellulose fibers low. A core theme of the session was the responsible use of wood and forests, with five speakers discussing the importance of circular concepts for cellulose feedstocks.

Dr. Peter Wood of Canopy, a non-profit organization that aims to protect and save the world’s remaining ancient and endangered forests, outlined the annual Hot Button Report that, together with the associated CanopyStyle audits, helps manmade cellulosic fiber producers better understand the impact their raw materials have on forests and global climate development. It also assists producers to accelerate efforts to deliver greater transparency in the supply chain and develop low-carbon, next-generation fiber alternatives.

Climate-neutral fibers

Austrian cellulosic fiber maker Lenzing says its business model is based on the use of wood from sustainably managed forests and plantations, which remove carbon from the atmosphere and turn it into raw materials from renewable carbon. The company aims to reduce carbon dioxide emissions by 50% by 2030 and to net zero by 2050, said senior sustainability expert Dr. Christian Schuster.

In its quest for carbon-neutral products, Lenzing has developed Refibra technology that enables the production of wood-based, regenerated cellulose fibers with recycled content.

Sustainably produced manmade cellulosic fibers can address many of the fashion industry’s issues as they are based on natural, renewable raw materials that are manufactured using closed-loop processes and are biodegradable at end of life. Further, cotton waste can be upscaled into fresh fibers, pointed out Mukul Agrawal, chief sustainability officer of Birla Cellulose.

The India-based fiber producer has developed and launched a range of eco-enhanced and circular products, such as Livaeco viscose and modal fibers made from wood pulp sourced from Forest Stewardship Council-certified forests; Purocel Eco viscose fiber for nonwoven applications; and Liva Reviva viscose fiber containing up to 30% pre-consumer cotton fabric waste.

The group is also working on alternative feedstocks, such as agricultural waste and microbial cellulose, and is collaborating with Australia-based biotechnology company Nanollose for a high-tenacity lyocell fiber made from bacterial cellulose.

Recycling and alternative raw materials

The session on recycling and alternative raw materials covered topics ranging from textile recycling – both cotton and regenerated cellulose fibers – to the use of hemp shives as raw material.

Canopy’s Valerie Langer extolled the advantages of low-carbon and circular feedstocks for next-generation manmade cellulosic fibers, such as Nanollose and Circulose. She pointed out that there is a lot of untapped feedstock in recycled materials, with 3.5 million tonnes of next-generation fibers expected to be produced by 2030.

Delegates heard that self-initiated cooperation and waste management will pave the way to a fully closed European material loop where textile waste is collected, recycled and reprocessed into new raw materials. In particular, the speakers demonstrated the importance of cooperation in recycling fabrics already in circulation.

Partnerships

For example, Lenzing is now working with Södra, Sweden’s largest forest-owner association with 53,000 members, to develop a 25,000 tonnes/year capacity to recycle textiles by 2025, producing OnceMore dissolving pulp and Tencel Refibra fibers, both with 50% recycled content.

Meanwhile, Sweden’s Renewcell and Germany’s Kelheim Fibres are collaborating to develop the commercial-scale production of viscose fibers from up to 10,000 tonnes of Renewcell’s Circulose 100% recycled textile material annually.

Manmade cellulose fibers, such as viscose and lyocell, cannot be recycled in the same way as cotton owing to their degree of polymerization, and therefore may not be a suitable feedstock for textile fiber production, pointed out Miguel Sanchis-Sebastiá of ShareTex, Sweden.

However, the polymeric properties of regenerated cellulose fibers mean they can be used in other applications, such as packaging materials, or the production of certain cellulose derivatives, such as cellulose acetate. The company has developed a recycling process for all cellulosic fibers as feedstock, regardless of their degree of polymerization.

New technologies

The session on new technologies addressed the processing of pulp, fibers and yarns aimed at achieving the most sustainable and efficient solutions. Topics ranged from processing cellulose with ionic liquids, material farming and chemical modification of pulp to functionalized fibers for “feel-good” textiles.

The final session introduced novel approaches to sustainable nonwovens and composites made from regenerated cellulose fibers. Presentations ranged from suitable approaches to meet the new requirements for wipes materials under the European Union directive on single-use plastics to alternatives for nonwoven raw materials made from natural fibers such as hemp and linen.

Innovation of the Year Award

A highlight of the conference was the Cellulose Fibre Innovation of the Year Award 2022. From the 12 nominations, six were given the opportunity to present their case during the event. The winner, chosen by delegates, was “Carbon Fibres from Wood,” presented by the German Institutes of Textile and Fiber Research (DITF), Denkendorf, Germany.

The other nominees were carbon-negative virgin fibers from straw by Fibers365, Germany (second place); Iroony hemp and flax cellulose by RBX Créations, France; a sustainable textile fiber without harmful chemicals by Spinnova, Finland; sustainable menstruation panties using application-driven fiber functionalization by Kelheim Fibres, Germany (third place); and Tencel-branded lyocell fiber made of orange and wood pulp by Orange Fiber, Italy.

The 4th International Conference on Cellulose Fibres will again be held in Cologne, Germany, from March 8–9, 2023. Contact: Dominik Vogt, Nova-Institut GmbH. Tel: +49 2233 481449. Email: dominik.vogt@nova-institut.de www.cellulose-fibres.eu