Sustainable fiber choices for wipes expand with upgraded lyocell shortcut with high dispersibility fibers

Lenzing’s industry partners seek out the company’s innovative fiber solutions to advance their product offerings, while combatting the growing issues facing the global environment. VEOCEL™ – Lenzing’s nonwoven brand – has been taking a proactive role in addressing these issues through its product innovation, technology, and fiber offerings.

“For many years now, VEOCEL™ has taken its role as a leading sustainable fiber brand in the industry very seriously,” says Claudio Zampino, Commercial Director, Specialty Applications for Global Nonwovens Business at Lenzing. “One significant global problem we are actively engaged in resolving became evident from global pandemic conditions, with tons of waste created from non-flushable wipes and their improper disposal.”

To illustrate, the global nonwoven wipes market consumed 1.5 million tons of nonwovens in 2022, valued at $20.8 billion. The global wipes market is forecast to consume 2.1 million tons, valued at $29.0 billion in 2027. Forecast growth rates for 2022– 27 are 7.4% (tons) and 6.8% (sales $).

This accelerated growth pattern is contributing to massive sewage blockages across continents and water pollution across the globe. Ocean water toxicity from micro-plastics, where polyester or polypropylene fibers are used for wipes, are especially harmful to our world’s vibrant sea life. According to a new study, over 170 trillion plastic particles are afloat in the world’s oceans, requiring urgent solutions.

In a recent study from North Carolina State University, the researchers concluded that “bioproducts, including those based on cellulose, are promising candidates for the development of nonwoven fibers and substrates with improved technical performance, degradability, and sustainability.”

The issue is clear … as is the solution: VEOCEL™ branded fibers as the sustainable choice for wipes manufacturers.

Nielsen IQ’s reveals that 78% of consumers say a sustainable lifestyle is important to them and 30% are more likely to purchase products with sustainable credentials.

“As a brand that cares for the health of our consumers and the environment, VEOCEL™ is a significant part of Lenzing’s ongoing mission to be a critical element in ‘value chain thinking.’ We focus on the needs of global consumers and work closely with our partners to meet these needs while adhering to elevated sustainability principles,” says Zampino.

To contribute to customer assurance and allow companies to share in the sustainable achievements of VEOCEL™ in its product advisories, VEOCEL™’s latest offering of lyocell shortcut fibers with an upgraded finish are tailored for the flushable market, bringing high dispersibility while maintaining good mechanical strength for the usage.

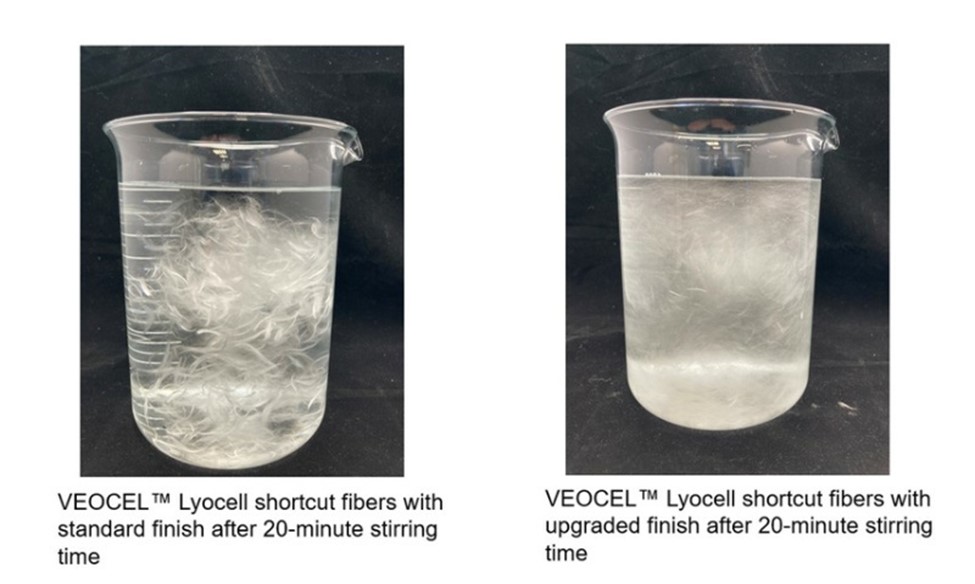

Lenzing AG lab dispersion test for lyocell shortcut fibers by VEOCEL™ after 20-minute stirring time

Flushable wipes which are made of lyocell shortcut fibers by VEOCEL™ with improved finish and are produced with adequate settings of the Roll Good Manufacturer, can disperse and degrade to meet current flushability guidelines as proven by mechanical disintegration and biodisintegration tests done at Lenzing R&D Center and third-party laboratory according to the International Water Services Flushability Group (IWSFG) specifications.

The upgraded finish also enhances efficiency of the wipe production process for manufacturers, improves the processability of fibers and helps to create higher quality products.

The new finish of the upgraded lyocell shortcut fibers offers protection against mechanical stress at commonly used water temperatures such as 0°C to 40°C during the wetlaid production process. This helps to avoid the creation of fiber lumps during the opening and dilution of fibers in preparation tanks. The finished product will also have enhanced physical quality and appearance thanks to the upgraded finish which improves web formation during the process.

Achieving the highest of industry-driven standards ultimately protects our water systems from harmful toxins and costly blockages. Manufacturers can be confident in their consumer education on retail packs when utilizing VEOCEL™’s lyocell shortcut fibers as they are unlikely to cause harm to wastewater conveyance systems or treatment plants.

“Lenzing is an active member of EDANA and INDA, two leading nonwoven associations in the world, with a joint mission of fostering greater eco-awareness in the nonwovens sector,” says Zampino. “We are keen to help progress the industry forward and contribute to a healthy environment now and in the future.”

Wipes manufacturers looking to enhance sustainability with viable, certified fiber solutions, should consider VEOCEL™’s upgraded lyocell shortcut fibers, the ingredient of choice for leading brands focused on a natural approach to everyday care.