Pollution at microscopical levels from plastic-derived products has become a global problem. Microplastics are any particles of plastic fragment smaller than 5mm. Polluting our environment every day, microplastics contain or carry hazardous chemicals that have a negative impact on nature and human health, and so their ingestion through water, or foods such as fish or shellfish, is of particular concern. One of the sources responsible for unleashing microplastics into the environment is domestic washing of garments. During the washing process, clothing sheds tiny microplastic fibers.

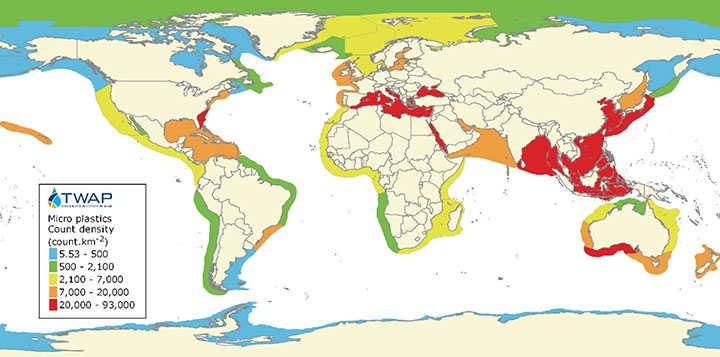

These microplastic particles are neither retained by washing machines nor filtered during the processing of wastewater and end up in rivers and oceans as a result. Once these particles enter the aquatic environment they interfere with the food chain, creating potentially longer-term risks for living organisms and entire ecosystems.

With rising concern among government bodies, NGOs and consumers about the impact of the fashion industry on the environment, it has become more important than ever for industry players to take serious action against microplastics pollution.

At the time of writing, there are no industry-wide standards or technical procedures that specifically look into the shedding quantity of microplastics from domestic laundry. Eurofins Softlines & Leather has developed a method to quantify garment fiber shed in the domestic laundry process, and identify the relationship between microplastics shedding and key attributes of garments such as fabric weight and fiber composition, as a way to support the fashion industry to better understand this key industry issue.

Notwithstanding the fact that microplastics pose a number of dangers, there are no regulations or mandates which evaluate or limit the amount of microplastics that a garment can release to water during the laundry process.

What are microplastics?

The unintentional release of microplastics to fresh and marine water globally is a concern for human health and the environment, and a number of potential risks such as reproductive harm, obesity and organ damage are not yet fully understood.

As a starting point, it is important to explain what exactly microplastics are.

The term microplastics (in some cases a shorter-form term, MP, is used) refers to small particles of polymeric material, which are less than 5 millimeters in size. Depending on their origin1, microplastics are categorized as either primary microplastics or secondary microplastics.

Primary microplastics are plastics that are dumped directly into the environment in the form of small particles that are:

- Intentionally added to products, such as cosmetics, shower gels or toothpastes, or

- Originate from the abrasion of plastic objects during the manufacturing process, use or maintenance, such as the microplastics resulting from tires or garments during the production and washing processes.

Secondary microplastics originate following the degradation of larger polymeric objects, in smaller plastic fragments, once exposed to the environment. This process occurs as a result of various environmental factors such as photo-degradation, oxidation, humidity, extreme temperatures, etc. Some examples of secondary microplastics are those that result from plastic waste, such as shopping bags, fishing nets or plastic cups.

In this paper, the analysis of microplastics shedding quantification refers to primary microplastics.

Harmful effects of microplastics on oceans and other water environments

Plastic is a material that is extremely common in our daily lives due to its versatile applications and uses. However, one of the properties of plastic, in general, is that its rate of bio-degradation is very slow – it can take “decades2 or even hundreds of years to decompose”.

According to a study3, 35% of primary microplastics found in the oceans worldwide can be attributed to the washing of synthetic garments, wheel abrasion while driving and city dust account for 28% and 24% of microplastics respectively.

Despite various studies that have been carried out that support this data, scientists are still further investigating the origins of microplastics and, according to a recent research study4, microfibers in oceanic waters are mainly composed of natural polymers. The study revealed that 79.5% of microfibers in oceanic waters are cellulosic, 12.3% of animal origin and 8.2% synthetic.

This data is important in terms of the growing demand for and production of synthetic fibers.

Global fiber production has more than doubled in the past 20 years and this growth is estimated to continue in the next decade, reaching 145 million MT in 2030, if current trends remain.

Of current fiber production globally (107 million MT in 2018), 62% can be attributed to production of synthetic fibers, with polyester the most produced fiber, accounting for 51.5% of total5 fiber production.

Beyond the pollution caused by microplastics, several additional studies reveal that microplastics can act as carriers6 of toxic substances, such as organic pollutants (POPs) and heavy metals, when these harmful substances adhere to the surface of microplastics when exposed to the environment.

While wastewater emitted from industrial and household sewage is processed at wastewater treatment plants to cleanse the water and remove toxic substances before the water returns to the water cycle, plants are unable to remove microplastics because of their extreme small sizes (< 5 mm). Although this has been known for a couple of years, no progress has been made to rectify the issue.

Shedding of microplastics from the domestic garment laundry process

As previously stated, 35% of primary microplastics originate from garment laundry. During the maintenance or washing process of textile garments, fabrics are subjected to mechanical stresses and abrasion that cause fragmentation of the fiber yarns, and consequently result in primary microplastics being shed into the water. These shed microplastics are carried around by the water and pass through the barrier of the wastewater treatment plants, ending up in different water bodies.

Toxic substances and heavy metals adhere to surface plastics, and upon reaching the ocean, various oceanic species such as zooplankton7 ingest microplastics as food. Consequently, microplastics which are shed from garments during the laundry process enter the food chain and can ultimately affect humans. While more research is required, scientists broadly believe that plastic being ingested by humans could have various negative results. Possible effects could include damage to liver, reproduction problems, developmental delays in children and chronic inflammation, among others. Given the bio-persistent property of plastic, the impact could be very long-lasting, and it could take a huge effort to rectify the problems we have been creating over the past two or three decades as a result of microplastic pollution.

Lack of industry standardization and technical solutions

Notwithstanding the fact that microplastics pose a number of dangers, there are no regulations or mandates which evaluate or limit the amount of microplastics that a garment can release to water during the laundry process. Additionally, the measurement of microplastics from textile sources has not been studied in great depth in order to create standards or methods that would help, on one hand, with objective evaluation and quantification, and, on the other hand, in finding possible solutions.

There are different technical solutions available on the market nowadays, further study though is required to determine how efficient and effective they are not only in terms of retaining or avoiding fiber shedding to water, but also in terms of how they avoid changing the properties of fabrics and garments, or the efficiency of a washing cycle.

In terms of quantification of microplastics, technical working groups for standardization and cross-industry agreements have recently been created on this to pursue the harmonized testing necessary to properly evaluate the problem and investigate feasible options to address the release of microplastics globally.

Eurofins microplastics shedding quantification

Eurofins Softlines & Leather has developed an internal method that allow our clients to quantify and characterize the microplastics shed by their garments or fabrics by simulating domestic washing.

This test is built on a method that is repeatable and reproducible, and provides results after multiple trials and stringent internal review.

The main objective of the test is to quantify microplastics shed during the washing process using standard and controlled conditions and parameters which will provide information about the quantity of microplastics shed during one or repeated washing cycles.

Method summary

The method can be used for the quantification of microplastics shed from fabric or garment samples.

Before testing, the samples are evaluated for basic textile properties, including composition, construction, and weight.

The simulated domestic washing is carried out using a hermetic drum that spins to generate movement, which simulates the mechanical action of a washing machine. The drum is also equipped with supplementary non-textile and non-polymeric materials, which simulate the abrasion caused during the washing process when a garment or fabric is in contact with other garments in a wash cycle.

All of the water used in the washing process is collected from the drum for filtration, and all particles suspended in the liquid are collected. For filtration, we use standard and certified mesh filters of different pore sizes, which help to segment the size ranges of particles shed during the washing.

This method can classify the particles shed by different size ranges and also provides information on the extrapolated quantification of particles shed by unit (i.e., garment), by weight or by surface. These three parameters are important in order to get an accurate picture of microplastics shedding in reality, as garments are produced in mass quantity.

In addition, by using state-of-the-art analytical techniques, SEM Microscopy, FTIR & Raman spectroscopy and chemical analyses, we can further identify types of fiber, providing more data for our customers.

Result analysis of Eurofins Microplastics Shedding Quantification

The results below follow an analysis of 598 samples received. All samples shed microplastics with different magnitudes.

Analysis observed four key factors and their correlation with microplastics shedding:

- Fiber length and yarn construction: it was found that fabrics and garments which are made with yarns containing fibers of longer lengths shed less particles into the water.

- Fiber composition strength: not all fibers carry the same ability to withstand the mechanical stress of the washing process. As a result of this and a combination of other factors (thermal stress, mechanical action and fiber strength), fibers in yarns can break and end up in the water. In general, polyester is more resistant than polyamide.

- Yarn and fabric surface finishing: the surface finishing of yarns and fabrics can result in different behavior of the fibers shed.

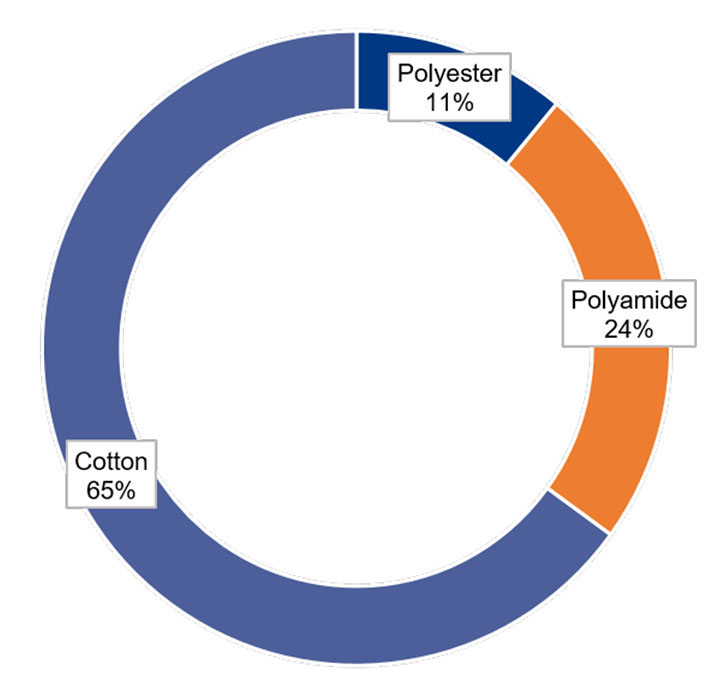

- Fabric composition: a determining factor when combined with factors described above. When comparing three different compositions of the most commonly used fibers (cotton, polyamide and polyester), it was found that as a result of its fabric composition, cotton sheds a larger quantity of fibers in comparison to polyamide and polyester.

Figure 1. Fiber shedding of different fabric types

The analysis shown in Figure 1 indicates the behavior of different fiber samples after one wash, specifically total particles shed in water calculated by milligram of particle per kilogram of fabric.

As part of the study, we also examined several common assumptions about microplastics shedding and outline our findings below:

- Fabric weight: it is assumed that the heavier the sample is, the more fibers are shed. Our data does not provide a clear link between the weight of a fabric sample and its shedding behavior.

- Fabric construction: when comparing fabrics of the same composition with similar weight, it cannot be concluded yet that the construction of the fabric directly results in a larger volume of microplastics shed.

- Origin of fiber: there is no evidence to suggest that fabrics of the same composition but made with “virgin” or “recycled” raw materials shed different amounts of microplastics.

Characterization of microplastics shedding

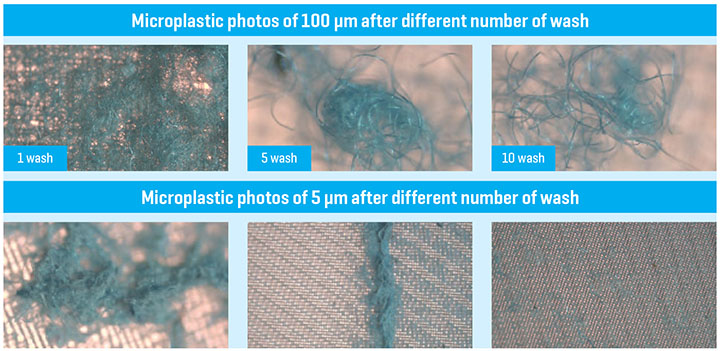

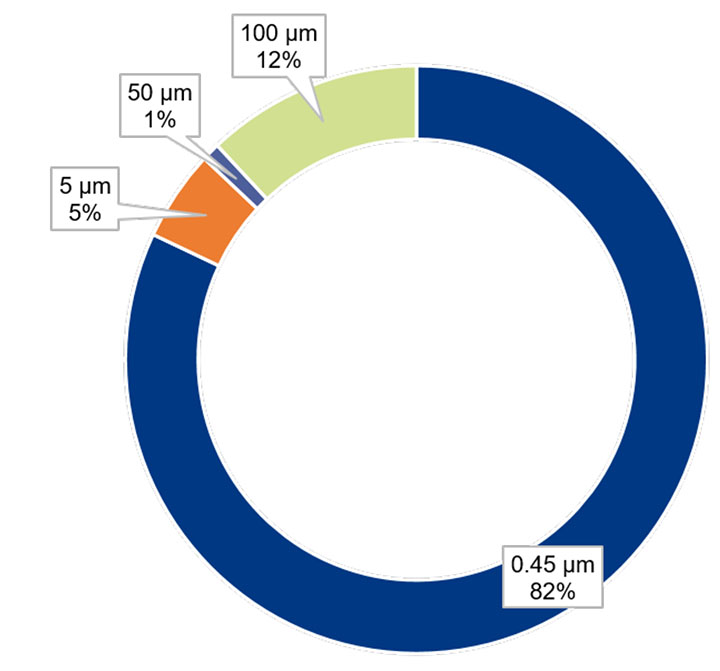

For all the tests carried out, Eurofins has classified and studied both the sizes of the particles and the microplastics shed in different samples and by different filter pore sizes.

The results obtained show that fabrics release fibers of different sizes, with length varying between 0.45 µm and >500 µm (as determined by using different filter sizes).

The results show that the length of fibers shed in higher quantities are those that are between 0.45 µm and below 50 µm in measurement, and are produced between one and 10 washing cycles.

After 10 washing cycles, some samples show a slight increase in releasing particles of larger sizes, even though the largest proportion of fiber shedding can still be attributed to fibers measuring in length between 0.45 and below 50 µm (Figure 2).

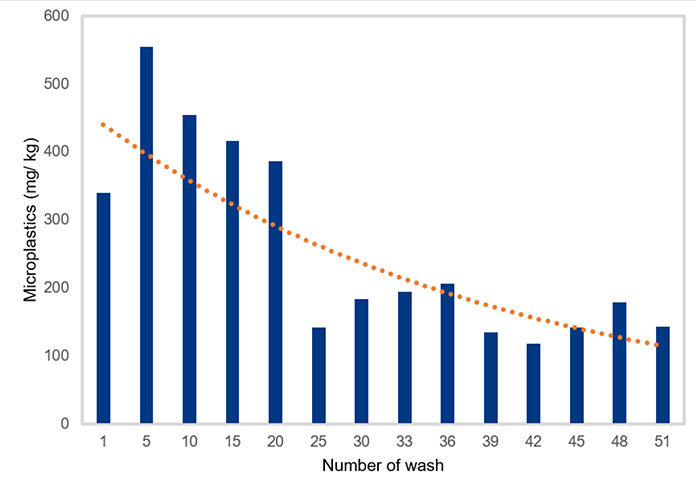

We also examined the amount of microplastics and particles shed during multiple washing cycles. Data from all the samples tested for multiple washing and drying (natural dry) cycles indicates that the quantity of microplastics and particles released by samples tended to reduce after multiple washing cycles. We have observed that the majority of microparticles and microplastic release occurs during the first 20 washing cycles (of samples studied).

Parting thoughts

The textile industry, as well polymer-related industries, is at the front line of a new environmental challenge which will require cooperation by all stakeholders in the supply chain in order to minimize the risks of microplastics to ourselves, our future generations and the environment.

Standards and methods to assess the impact of microplastics, and most importantly, solutions should be spearheaded by a consolidated effort at each step of the supply chain – from manufacturing more durable and shed-resistant products to reducing the amount of microplastics reaching water bodies.

Eurofins Softlines & Leather offers the full suite of solutions that every buyer and supplier will require throughout their entire textile and footwear supply chain journey. Through our Technical Competence Centres in Spain and the United Kingdom and our laboratories in Asia, Europe and United States, our sustainability solutions, testing services, as well as regulatory and compliance services, we can support customers to ensure their product quality and compliance. We participate in different industry bodies and associations that drive product safety and compliance in different parts of the world, and will take part in the technical working groups of for standardization and cross-industry agreements on microplastics.

References

1.GESAMP (2015), “Sources, fate and effects of microplastics in the marine environment: a global assessment” (Kershaw, P. J., ed.), (IMO/FAO/UNESCO-IOC/UNIDO/WMO/IAEA/UN/UNEP/UNDP Joint Group of Experts on the Scientific Aspects of Marine Environmental Protection), Rep. Stud. GESAMP No. 90, 96 p.

2. Ioakeimidis, C. et al., “The degradation potential of PET bottles in the marine environment: An ATR-FTIR based approach,” Sci. Rep. 6, 23501; doi: 10.1038/srep23501 (2016).

3. Boucher, J. and Friot D. (2017), “Primary Microplastics in the Oceans: A Global Evaluation of Sources,” Gland, Switzerland: IUCN. 43pp.

4. Suaria et al., Sci. Adv. (2020), “Microfibers in oceanic surface waters: A global characterization,” DOI: 10.1126/sciadv.aay8493.

5. Preferred Fiber & Materials Market Report 2019, Textile Exchange.

6. F Yu, C Yang, Z Zhu, X Bai, J Ma (2019), “Adsorption behavior of organic pollutants and metals on micro/nanoplastics in the aquatic environment,” Science of The Total Environment 694, 133643.

7. Environ. Sci. Technol. 2013, 47, 12, 6646–6655 (2013), https://doi.org/10.1021/es400663f.