In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: April 28, 2023

Lectra Inaugurates Manufacturing Facility in U.S.

Lectra, a major global player in the fashion, furniture and automotive markets, celebrated the inauguration of its manufacturing facility in Tolland, Connecticut in April.

The implementation of operations in this facility marks an important milestone in Lectra’s 2023-2025 strategic roadmap as the company expedites bringing manufacturing in-house for improved quality and customer satisfaction.

With this additional factory, Lectra’s complete line of single ply cutters, including the Z1, Taurus, and DCS series, will be manufactured in-house, enabling Lectra to meet customer demands quicker, while reducing lead times by 60 percent. A larger investment in inventory coupled with a move towards leaner and more modern production systems will also enable Lectra to provide a higher quality service for customers.

Daniel Harari, CEO of Lectra, honored the inauguration with a ribbon cutting ceremony along with the company’s executive leadership team, who toured the facility to observe the extensive manufacturing workspace and industry leading equipment.

“A big part of our strategy is focused on manufacturing in-house and across our main regions. The opening of our Tolland manufacturing facility will enable us to better control production.” said Daniel Harari. “It will also enable us to hire more employees and give back to the communities where we live and work. As we look to the future, our focus remains on providing best-in-class Industry 4.0 solutions for our customers and further developing our three strategic market sectors.”

At the ribbon-cutting event, Daniel Harari described Lectra’s 4.0 strategy and outlined the Corporate Social Responsibility pillar, aimed at integrating social, ethical and environmental responsibilities within Lectra’s strategy. The facility will enable Lectra to reduce the environmental footprint of its activities and contribute to the design of eco-responsible offers, as part of the company’s global commitment to sustainability.

Milliken & Company Returns to Forbes Best Employers for Diversity List

Milliken & Company, a global diversified manufacturer with materials science expertise, has been included on Forbes Best Employers for Diversity list for the second year in a row. The 2023 list, comprised of 500 U.S.-based companies, recognizes employers across 25 industries who are prioritizing diversity-related best practices within their organizations.

“At Milliken, we’re committed to inclusion,” said Milliken President and CEO Halsey Cook. “By fostering diverse teams globally, we get better solutions to the challenges facing our customers.”

Lenzing Offers Locally Produced TENCEL™ Fibers to Chinese Customers

The Lenzing Group, a world-leading provider of specialty fibers for the textile and nonwoven industries, has successfully completed the conversion of a production line from generic viscose to TENCEL™ branded modal fibers for textiles and clothing at its facility in Nanjing, China. Lenzing is therefore in a position to offer its Chinese customers locally produced TENCEL™ fibers for the first time and meet the structural growth in demand more quickly. Thanks to the conversion of the production line with a nameplate capacity of 35,000 tonnes per year, the fiber portfolio of the Chinese production site now solely consists of eco-friendly specialty fibers. In addition, Lenzing also offers LENZING™ ECOVERO™ branded fibers for textile applications and viscose eco fibers for nonwoven applications in China.

Celebrations for the launch of the new production line took place on Tuesday, April 18, 2023 as part of a customer event. Lenzing is investing EUR 100 million in its Chinese site to further reduce carbon emissions and upgrade the product portfolio. The company is currently implementing a gradual shift to green energy at its Chinese production site, where electricity will be solely derived from renewable sources from 2023 onwards. In 2019, Lenzing set itself the target of halving its specific carbon emissions by 2030 and becoming carbon-neutral by 2050. Its carbon reduction target has been confirmed by the Science Based Targets Initiative. This makes Lenzing the world’s first producer of cellulosic fibers to have a scientifically recognized climate target.

Archroma Announces CEO Transition

Archroma, a global leader in sustainable specialty chemicals and solutions for the textiles, packaging & paper, paints and coatings industries, announced its transition plan for the role of Chief Executive Officer (CEO). Heike van de Kerkhof, CEO of Archroma since January 2020, will step down effective April 30, 2023, to focus on other career opportunities. Mark Garrett, a seasoned industry executive, will assume the role of interim CEO. Archroma’s Board of Directors has initiated a comprehensive search process for installing a permanent CEO and has retained a leading executive search firm to evaluate both internal and external candidates.

Trelleborg Announces MMI Textiles as TACTWEAR™ HANK Distributor

Trelleborg Engineered Coated Fabrics operation announced the signing of a distribution agreement with MMI Textiles for TACTWEAR™ High Abrasion Neoprene Kevlar® (HANK).

MMI Textiles will offer TACTWEAR™ HANK in a variety of weights, colors, and quantities – effective immediately. This partnership will enable Trelleborg to better serve a broader range of customers in a more responsive manner.

Purpose-built TACTWEAR™ HANK is formulated to meet the demands of law enforcement, first responders, defense, and extreme recreational activities and sports. The rubber-based coated material boasts excellent abrasion resistance and is flexible, flame resistant, waterproof, laser cuttable in well-ventilated areas, and is manufactured in the USA to meet Berry compliance standards.

www.trelleborg.com

Milliken & Company Among America’s Most Innovative Companies

Diversified manufacturer Milliken & Company has made America’s Most Innovative Companies list for the first time this year.

Presented by Fortune and Statista Inc., the America’s Most Innovative Companies list highlights companies nationwide that excel in a holistic approach to innovation.

Milliken is one of 11 companies in the industrials sector on the 2023 list. Statista surveys employees and experts to assess product and process innovations and collaborates with LexisNexis to analyze the quantity and value of a company’s patents. These three components come together for a final score, and the top 300 U.S. companies are listed as America’s Most Innovative Companies.

“At Milliken, we draw on our materials science expertise to maintain a portfolio of more than 11,000 products used in the textile, specialty chemical, floor covering and healthcare industries,” said Milliken president and CEO Halsey Cook. “Innovation is a core value, and it is firmly embedded in our culture.”

Noble Biomaterials Launches New Ionic+ Fabric Solution

Noble Biomaterials has announced the release of the new Ionic+ fabric solution, Ionic+ Durable. Noble Biomaterials, a leader in antimicrobial and conductivity solutions for soft surface applications, produces advanced material technologies designed for applications in the performance apparel, healthcare, industrial, and emerging wearable technology markets.

Ionic+ Durable is a silver-based fabric finish that is an effective, expedient way to deliver antimicrobial benefits. It is applied at the finishing stage, allowing for maximum design freedom and production flexibility. The novel solution meets or exceeds state-of-market performance, and while the application has achieved a 50x wash durability rating, the self-cleaning, odor-eliminating ionized silver will ensure fewer washes to help conserve water, energy, and natural resources, as well as reduce fabric degradation over time, according to Noble Biomaterials.

The company’s history of ground-breaking innovation, from the first EPA-approved silver antimicrobial, to the first silver technology in an FDA-approved medical device, to the first antimicrobial on the International Space Station, showcases their commitment to pushing the barriers of material science with its proprietary silver-coating technology. With the addition of the new Ionic+ topical treatment to an already robust portfolio, this new offering is the capstone that allows the company to offer the most advanced antimicrobial system on the planet for clothing, footwear, luggage, bedding, medical wound care products, and more, Noble Biomaterials said in a press release.

New “Fiber Recycling Initiative” by TENCEL™ Spotlights Circularity

Lenzing Group, a leading global producer of wood-based specialty fibers, introduced the initial phase of the “Fiber Recycling Initiative” by TENCEL™ alongside its valued mill partners, Artistic Milliners in Pakistan, Canatiba in Brazil and Textil Santanderina in Spain.

Dedicated to driving circularity in the global textile industry, the new initiative kicks-off with the production of denim fabrics derived from mechanically recycled TENCEL™ branded lyocell fibers. With usage of pre-consumer lyocell waste at a commercial scale, the initiative redefines the circular future of a sustainable denim industry globally.

“Brands and consumers count on us to lead the change towards a more sustainable industry value chain,” said Tuncay Kılıçkan, head of Global Business Development, Denim, at Lenzing. “As we constantly seek ways to improve circularity across various components of the textile industry, our like-minded, decades-long value chain partners have innovatively discovered the mechanical recycling of TENCEL™ Lyocell fibers in denim production. While such concept is still relatively new to the wider industry, the development of the “Fiber Recycling Initiative” by TENCEL™ sets out to promote the benefits and unleash the full potential of the new circular fabric.”

The fibers are also identifiable in end products, ensuring traceability and transparency of production processes. With the ability to be traced back to their sources, the use of mechanically recycled TENCEL™ Lyocell fibers can be documented and verified, ensuring greater accountability and transparency in the supply chain.

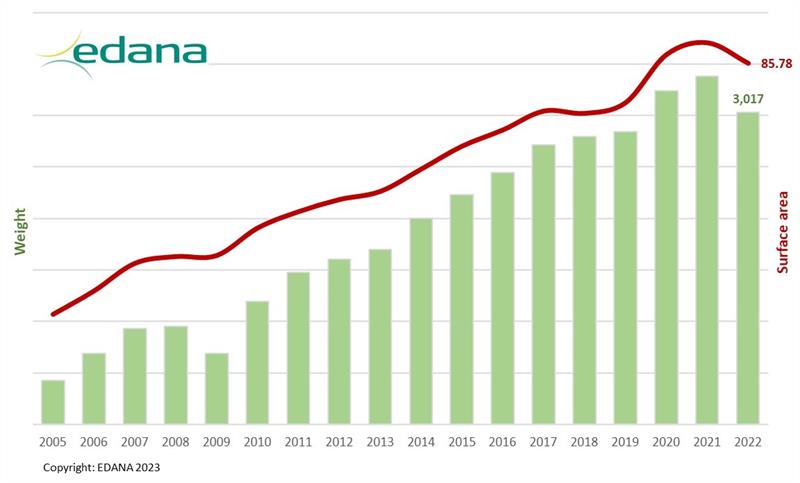

European Nonwovens Production at Higher Level Than Pre-COVID

EDANA, the leading global association advocating the benefits of nonwovens for society, released an overview of the high-level figures from the EDANA Statistics Report on Nonwovens Production and Deliveries for 2022.

After a spike caused by the exceptional increase in demand for nonwovens materials in 2020 and 2021 due to the COVID-19 pandemic, (+9.3% in 2020-2021), production in Greater Europe (including Western and Eastern European countries, Turkey, Belarus, Russia, and Ukraine) is back on track. The figures, while lower than during COVID-19, have returned to pre-pandemic levels and we can again see a steady growth trend despite the economic and energy crisis, and the war in Europe.

In 2022, compared to data from 2019, nonwovens production in Greater Europe increased in volume by 3.3% to reach 3,017,085 tonnes, and by 9.1% in surface area resulting in 85.8 billion square meters of nonwovens being manufactured.

Killer Brand Uses Sorona® In Launch of Sustainable Yarn

CovationBio, a global company offering bio-based solutions, recently announced the latest innovation from its bio-based polymer brand Sorona®, in collaboration with Killer (KKCL in National Stock Exchange, India), a young, trendy, vibrant fashion brand with an attitude. The release of this collection brings an innovation to the shirting world with Sorona® polymer treated in a hank dyeing process for the first time. The new application for shirting offers a two-way stretch with Sorona® polymer removing the need for spandex.

The collaboration between CovationBio and Killer combines cotton and Sorona® polymer to create a garment with exceptional comfort, moisture management, luxurious drape, and a superior hand feel in addition to vibrant color, and outstanding stretch and recovery. The new global collection expands the future of sustainable textiles in casual fashion, streamlining the method for dyeing Sorona® polymer and reducing the processing time for colored stretch fabrics made with Sorona® polymer.

Sorona® polymer, made from 37% annually renewable plant-based ingredients, offers a high-performing, responsibly sourced material option. Fibers made with Sorona® polymer are currently used in various apparel applications, including athleisure and athletic wear, insulation, swimwear, outerwear, suiting, faux fur, and more. Sorona® polymer is a USDA Certified Biobased Product, has earned Class 1 certification as an OEKO-TEX® STANDARD 100 products, and is bluesign® approved.