In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: July 25, 2023

INDA Opens Registration and Tabletop Reservations for Hygienix™ 2023

INDA, the Association of the Nonwoven Fabrics Industry, announced that registration and tabletop exhibit reservations are open for the ninth edition of Hygienix™, November 13-16, New Orleans, Louisiana. More than 450 absorbent hygiene and personal care professionals from around the world will gather for four days of networking, presentations, and business opportunities.

The theme for this year’s Hygienix is “Shaping the Future of Absorbent Hygiene.” The event will focus on the market’s continued growth with presentations on sustainability, technology advancements, disruptive small brands, and market data and trends. Hygienix will also offer a workshop on absorbent hygiene systems led by Jim Robinson, Absorbent Hygiene Insights, LLC, Monday, November 13th. The full Hygienix program will be announced at a later date.

INDA is also introducing a new element for Hygienix – pre-conference webinars. Carlos Richer, Principal, Diaper Testing International, will present insights and trends in diaper design in the U.S. market and Heidi Beatty, CEO, Crown Abbey, LLC, will share her expertise in the absorbent hygiene sector.

More than 50 companies will showcase their innovations and technologies during the evening tabletop exhibits and receptions. Participants will be able to discuss their needs with technical leaders and source better solutions for their products, Nov. 14-15.

Nominations are being accepted through August 7th for the Hygienix Innovation Award™. Three finalists will be selected to present their absorbent hygiene products on Tuesday, November 14th to hundreds of senior-level professionals. The winner of the Award will be announced at the end of the event, Thursday, November 16th.

Last year’s award recipient was Pads on a Roll™ by Egal Pads. “Participating in the Hygienix conference (and winning the award) was an incredible opportunity for Egal on so many fronts,” said Penelope Finnie, CEO, Egal Pads, Inc. “First, it was amazing to get such incredible validation of our product from those who have literally seen it all. As a newcomer to the industry, it was an incredible opportunity to learn from so many veterans. The connections that were created have really helped move us forward. I credit winning the award with providing much of that momentum,” Finnie continued.

PFAS Alternatives Act

Several members of Congress recently introduced the PFAS Alternatives Act. The bipartisan bill would support the development of next-generation safety materials for firefighter turnout gear that are free of per- and polyfluoroalkyl substances (PFAS).

Globe Manufacturing Company, one of several U.S. companies that makes structural turnout gear for firefighters, supports the PFAS Alternatives Act because it will help the industry meet firefighters’ call for PFAS-free gear.

WOW Breaks Attendance Records

INDA, the Association of the Nonwoven Fabrics Industry, announced the successful conclusion of the World of Wipes® (WOW) International Conference, July 17-20, Atlanta, Georgia. More than 495 senior-level leaders convened for new intelligence, connections, and business, which was a record turnout for the WOW event.

The 17th edition of WOW featured almost 60 tabletop exhibits, 26 presentations, and two pre-conference webinars. The program introduced Lightning Talks, “supersized elevator speeches” covering new trends, products, and ideas, and a 1.5-day revised WIPES Academy training course. WOW also featured a mentorship program for participants new to the wipes industry.

The WOW speakers shared their expert insights in these key topics:

- Inflation, Supply Chain Issues, Capacity/Demand Balance

- Plastic Policy: Closing the Intention-Action Gap

- Sustainability and Manufacturing Practices

- Consumer Market Data and Trends

- Wipes Advancements

- Transparency in the Supply Chain

- Regulation, Innovation, Standards & Education in Flushability

“WOW addressed the key issues facing the wipes industry. Participants acquired actionable intelligence to assist in their strategic planning for the coming year and beyond,” said Tony Fragnito, INDA President. “Once again, we saw a strong showing of innovative products on display in the tabletop exhibits and from the Award Finalists’ presentations,” Fragnito added.

Lenzing Introduces New Resource-Efficient Dyeing Approach for TENCEL™ Lyocell Fibers

Lenzing Group, a leading global producer of wood-based specialty fibers, has introduced a new approach that covers yarn pre-treatment and knitting technique to achieve aesthetics that resemble the wash-down effects of traditional dyeing in ready-to-wear and knit garments.

To address the pollution caused by dyeing and finishing in the textile industry, the new approach will significantly reduce environmental impact and is ideal for use on pre-treated fabrics and yarns made with TENCEL™ Lyocell fibers. The approach also complements the wet-processing and production facilities of fabric mills, bringing added benefits for value chain partners.

In traditional dyeing, multiple washes using a significant amount of water, energy, dyes and chemicals may be required to achieve a designated shade of color. With the new approach, only one round of dyeing is required, reducing water, energy and chemical usage by up to 50%, 40% and 90%, respectively.

With the new approach’s direct application to TENCEL™ Lyocell fibers or TENCEL™ Lyocell with REFIBRA™ technology, different shades of color, wash-down or fade-out effects can be customized. This makes it ideal to produce ready-to-wear, knit apparel and denim-looking garments in various color shades.

Messe Frankfurt Becomes Shareholder of Kingpins Show

Messe Frankfurt, a global leader in trade fair organization, and Kingpins Show, the premier tradeshow specializing in the denim industry, announced a strategic partnership that will further strengthen their commitment to fostering innovation, collaboration, and growth within the denim community.

Messe Frankfurt’s new role as a shareholder in the Kingpins Show elevates the textile portfolio’s presence in the denim industry as well as solidifies their dedication to supporting the industry’s development.

Messe Frankfurt is the world market leader in trade fairs for the textile industry. With a unique portfolio currently comprising around 50 international trade fairs in 11 countries. These form the core of Texpertise, the textile business network, which stands for Messe Frankfurt’s entire textile commitment. Texpertise Network covers the entire value chain of the textile industry and, as a central communication platform, provides valuable information on the textile trade fair brands.

The Kingpins Show will continue to operate independently, maintaining its distinct identity and the essence that has made it a must-attend event for denim enthusiasts worldwide. As a shareholder, Messe Frankfurt brings its global network, unparalleled resources, and industry- leading expertise to strengthen the Kingpins Show’s position as a premier denim platform.

TSG Finishing Amplifies Its Chemical Compound Offerings

TSG Finishing LLC recently announced the strategic expansion of its chemical compound sales. The move brings more than a century’s worth of specialized chemical and coating knowledge directly to its clients.

With an acute understanding of synthetic latex polymers such as acrylic, SBR, vinyl, polyurethane, and many more, TSG Finishing integrates raw materials from a wide range of manufacturers to create custom formulations. Their expertise extends to C6 and C0 DWR’s, flame retardants, and antimicrobials, as well as a host of non-standard products such as liquid absorption and stiffeners.

Said CEO Brian Rosenstein: “Our expansion into chemical compound sales underscores our commitment to fostering scientific rigor, innovation, and technical excellence within our clientele’s coating processes. Our custom formulations and compounds are meticulously crafted to meet each client’s unique needs, promising to elevate their respective operations to new heights.”

Patrick Keese New Floor Covering Business President at Milliken

Milliken & Company, a diversified global manufacturer with a portfolio of textile, specialty chemical, floor covering and healthcare innovations, recently named Patrick Keese as its executive vice president and president of Milliken’s Floor Covering Business.

Effective July 25, Keese will lead Milliken’s international floor covering operation, spanning four continents and 290 product collections.

Most recently serving as SVP and general manager of Altium Packaging, Keese has an extensive background in international business leadership. At Altium, he led more than 1,300 employees at 30 locations to produce plastic and packaging components.

Prior to this, Keese worked for Sonoco Products Company, a global provider of consumer packaging, industrial products, protective packaging and healthcare packaging solutions based in Hartsville, S.C., in both manufacturing and commercial roles. He holds a Bachelor of Science in industrial management and marketing from Clemson University, as well as certifications in various executive development programs at Columbia University and the Rensselaer Hartford Graduate Center.

Compostable Wipes from Neutrogena

Lenzing has partnered with Neutrogena to transition the production of its market-leading makeup removal wipes to 100% Veocel plant-based fibers. The new wipes utilize Veocel branded fibers made with renewable wood from sustainably managed and certified forests. The makeup removal wipes can be composted at home in 35 days, eliminating waste which ends up in a landfill.

Conventional makeup removal wipes are popular because of how convenient they are – users simply wipe off makeup after a long day. However, popular makeup removal wipes mostly contain polyester, polypropylene, and rayon, making them unable to decompose. Their one-time usage means they are sent to landfills or many people flush them down the toilet, clogging the sewer system or leaking microplastics into waterways.

The goal of this new partnership is to develop a product that has moved on from synthetic materials to an entirely cellulose-based solution. These new Neutrogena makeup removal wipes are described as ultra-soft, while also retaining the same effective cleaning function of its predecessors, with oil-based technology and micelle-infused water.

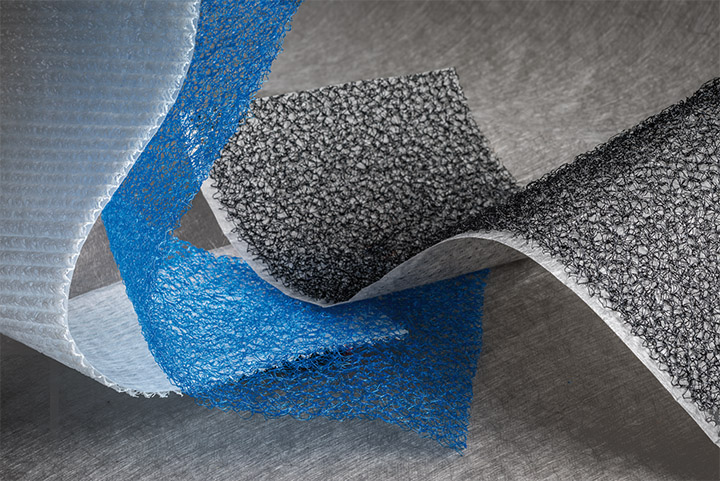

Freudenberg Adds Geosynthetics Line in China

Freudenberg Performance Materials has begun operating a new geosynthetics production line at its site in Changzhou, China. The new line will significantly increase capacity for its Enka Solutions business to supply customers in the APAC region while also allowing it to serve customers in diverse technical markets with finished and semi-finished products.

Freudenberg inaugurated the new line in Changzhou at an opening ceremony on July 13th.

The new production line in Changzhou complements the manufacturing operations in Obernburg (Germany) and Asheville (North Carolina, USA).

With a global manufacturing presence on the three different continents Europe, Asia and America, Freudenberg says it can now serve markets locally and deliver Enka Solutions products faster and efficiently. This will not only help to better meet customer needs, but also reducing the company’s environmental footprint by increasing local production.

Hickory Brands Inc.: 100 Years of Innovation

Hickory Brands Inc. celebrated its 100th anniversary of U.S. craftsmanship during a weeklong celebration early in July. During the week, suppliers from around the country visited the company’s offices and plant in nearby Longview, N.C.

From its inception in 1923 as Hickory Lace Braiding Co. and the pioneer of packaged replacement shoelace systems and dispensers as Old Hickory Shoelace, the narrow textiles producer has expanded its portfolio to not only include shoelaces, but also cord, webbing and braid used in the outdoor, footwear, fashion, military and industrial segments manufactured at its family-owned factory.

From humble beginnings in the basement of a textiles mill here, to products that would later circle the globe on the feet of the U.S. military and Olympic athletes alike. HBi has laced up the American workforce from fine dress shoes on Madison Avenue to the boots that brought us through the Industrial Revolution and world wars.

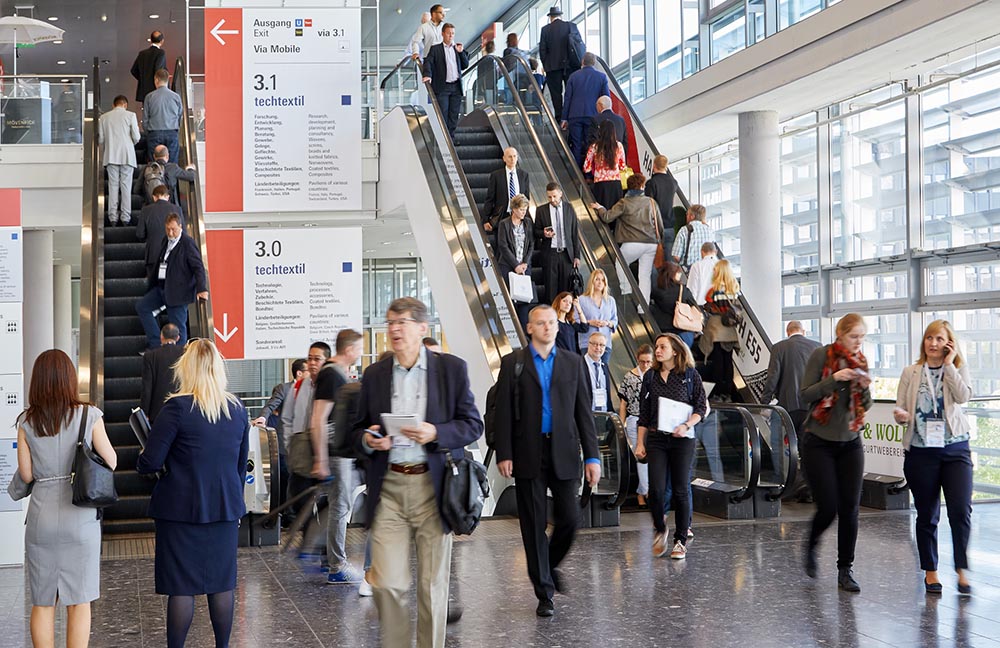

Record Attendance for ITMA23

ITMA 2023 was a resounding success, according to the organizers. The event welcomed a record 111,000 visitors from 143 countries during its week-long run in Milan last month. With a gross exhibition space of 200,000m² that showcased 1,709 exhibitors from 47 countries across 20 product chapters, ITMA sealed its reputation as the innovation launchpad of the textile industry, setting the trends for the industry to transform towards digitalization and sustainability.

“This edition has been a great success with the number of visitors higher than the previous exhibition in 2019,” said Ernesto Maurer, president of organizer CEMATEX. “At this ITMA, the transformation journey toward digitalization and sustainability has taken a huge leap forward. It has been a mega gathering with the presence of stakeholders of the entire textile and garment-making ecosystem. CEMATEX associations and their member companies, as well as all other exhibitors, are delighted with the results as the exhibition has surpassed all our expectations.”

Successful Event for Canadian Textile Industry at ITMA

A delegation of 35 companies and organizations from Quebec and Canada, bringing together over 100 executives from the technical textile and garment industries, attended ITMA 2023, the world’s biggest trade show in the area of manufacturing innovation and technology, from June 8 to 14, 2023, in Milan, Italy.

Organized by TechniTextile Québec, CTT Group, the mmode Cluster, Vestechpro and the Comité sectoriel de main-d’œuvre de l’industrie textile du Québec (CSMO Textile), the mission proved a tremendous success. It enabled business leaders to discover the latest technological advances, which are essential to keeping their manufacturing operations up to date.

The delegation brought together companies specializing in the development and production of technical textiles intended for the furniture, construction, environment, civil engineering, apparel, transportation, sports and leisure, and personal protection markets, as well as the industrial and medical sectors.

The growing demand for innovative technical materials, enthusiasm for buying locally, repatriation of some production operations previously carried out abroad and labor shortage are all factors prompting organizations to make major investments in automation and integrating cutting-edge technology into their manufacturing activities.

A survey of participants conducted after the trade show revealed that 90% of companies expect to invest millions of dollars during the next year to acquire new equipment. In 70% of cases, this equipment will meet new production needs, while in 50%, it will replace equipment at the end of its useful life. The figures clearly indicate that the industry’s growth is set to continue. These strategic investments are aimed at accelerating the transition to 4.0—a key initiative for improving the technical textile industry’s productivity.

Monforts Secures Orders from Central and South America

Finishing machinery specialist Monforts has secured a significant number of major orders from textile manufacturers in Central and South America recently, and was very pleased to welcome an unexpectedly high number of visitors from the region to its stand at ITMA 2023 in Milan from June 8-14.

Among new orders are those for three Montex stenters delivered to the AustralTex Group in Argentina and a further Montex range to denim manufacturer CIT in Brazil. Guatemala’s Global Textiles placed an order for its second Montex stenter, while Mexico’s Zentrix ordered its third and Avante, also in Mexico, has opted for its sixth.

Elsewhere, orders have also been placed for the delivery of three new Montex stenters to one of Pakistan’s major corporations, as well as a new Thermex dyeing range to nonwovens manaufacturer Orsa in Italy. Further orders – both for new machines and retrofit modules – are now anticipated following ITMA 2023, which attracted over 111,000 visitors to Milan.

Amba Projex Supports Growth for India’s Candour Techtex

Candour Techtex, a Melegaon JR Group company, is so happy with the latest coating and lamination line supplied by the UK’s Amba Projex it has immediately ordered a second, wider one to meet booming demand.

“We are very pleased with how this installation went,” said Amba Managing Director Barry Goodwin. “Our team installed the machine and got it running from Day One, producing three-pass blackout thermal linings and technical laminations to a quality never before seen in India.”

Based in High Peak near Manchester, BTMA member Amba Projex has over 40 years’ experience in the design and manufacture of special purpose technical textile machines, with coating and laminating installations around the world.

“We serve manufacturers in many different countries with an experienced network of agents on the ground and in India we are brilliantly supported by Jayessh S Nanavati and his team at Sainite Exports,” said Goodwin. “They have been instrumental in securing sales for us in India. We strive to provide the most effective machinery, on time and within budget and also provide consultation services for customers based on our extensive process know-how.”

Amba will be working closely with Candour over the next five years, to establish an Indian technical textiles powerhouse capitalizing on the UK technology provider’s long experience in the field.

Formerly Chandni Textiles Engineering Industries, Candour Techtex of the Malegaon JR Group assumed its new name in 2022 to reflect its focus on a wide range of technical textiles at its new plant in Malegaon in the Nashik District of Maharashtra.

The company was founded in 1986 and at its existing plant in Ankleshwar, Gujarat, produces an annual 1.2 million meters of light velvet fabrics mainly for the domestic market for apparel and light home furnishings. In 2020 it also began operations at a plastic molded components division in Gonde, Nashik, with a capacity of 4,500 tons per annum.

Kelheim Fibres: Change in Management Team

After nearly 30 years with the company, Matthew North, Commercial Director at renowned viscose specialty fiber manufacturer Kelheim Fibres, retired July 1, 2023. Throughout his long and successful career, he has played a significant role in transforming Kelheim Fibres from a supplier of standard fibers to the European textile industry into a supplier of predominantly customized specialty fibers for the hygiene, specialty paper, and textile industries.

Craig Barker, CEO of Kelheim Fibres, said, “On behalf of the entire team, I would like to express our gratitude to Matthew for his outstanding work over the past decades. His wealth of experience, calm nature, and British humor will be greatly missed. We wish him all the best for his exciting new chapter in life. At the same time, we wish Mark von der Becke and Dr. Marina Crnoja-Cosic much success in the new responsibilities they have now assumed.”

Mark von der Becke will assume the position of Sales Director and become part of the management team at Kelheim Fibres. The 48-year-old brings extensive experience in sales, marketing, and key account management. He has held various leadership positions in renowned companies such as Hoechst, Clariant, and DS Smith in Germany, Switzerland, and China. He is known for successfully developing and implementing strategy and change programs.

Dr. Marina Crnoja-Cosic, who has been serving as Director of New Business Development and a member of the management team at Kelheim Fibres since 2020, will take on the responsibility for marketing and communications. She has already proven herself as a dedicated and competent leader and will now drive the further development of the marketing strategy and communication with customers and partners.

PFNonwovens Achieves Continued Growth

Global nonwoven fabric manufacturer PFNonwovens celebrated its 5th anniversary marking significant achievements including expansion initiatives and commercializing innovative solutions which underscore its commitment to customers, consumers, and the planet. With a focus on supreme softness, customization, ultimate protection, and sustainability PFNonwovens continues to improve lives while driving a more sustainable world.

PFNonwovens expanded its production capabilities to meet increasing global demand for high-quality nonwoven fabrics and enhanced supply resiliency for the company and its partners. The latest investments deliver tailored solutions focused on supreme softness, customization, ultimate protection, and sustainability. PFNonwovens prioritize continuous investment in cutting-edge technology to achieve unparalleled production efficiency. As a result, they can manufacture materials with a lower weight per square meter, all while delivering performance and quality that matches or exceeds those of materials with higher weight per square meter. Some new innovative materials that have been developed are Acquisition Distribution Layers, Pants Waist-Belt Nonwovens for baby and Adult Inco as well as Fastening components.

In 2023, the company added the latest state-of-the-art Reicofil production line in the Republic of South Africa, enhancing its supply capacity in the region. Just a year before, in 2022, another Reicofil line was added in Hazleton, Pennsylvania, USA, reinforcing PFNonwovens’ commitment to serving the American market. This line combines R5 technology with high-speed texturing and aperturing methodology to serve the Premium product categories. Additionally, PFNonwovens introduced an advanced Aperturing / 3D Embossing line in Czech Republic, broadening its manufacturing capabilities to meet diverse market needs.

PFNonwovens’ commitment to sustainability is recognized through prestigious certifications. The Znojmo facility in Czech Republic holds the EcoVadis Gold certification, while facilities in South Africa, Egypt, and the United States have achieved EcoVadis Silver certification. These certifications affirm the company’s dedication to responsible and environmentally conscious operations.

PFNonwovens actively observes and encourages powerful sustainability trends. As part of its ongoing innovation efforts, PFNonwovens recently launched a groundbreaking nonwoven fabric based on 100% Bio Polymer, developed using the spunlaid technology. This advancement highlights the company’s dedication to providing sustainable materials that deliver exceptional performance, on par with petro-based resins, for the biggest and the most demanding nonwoven category, Personal Care. This innovative material delivers outstanding performance across all baby diaper applications.

PFNonwovens also embraces Mass Balance raw material sourcing, ensuring responsible and sustainable procurement practices. Additionally, PFNonwovens has obtained ISCC Plus Certifications in the Czech Republic, underscoring its commitment to sustainable sourcing and traceability.