In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: March 13, 2024

Nonwoven Professionals Are Invited to Present at IDEA®25

INDA, the Association of the Nonwoven Fabrics Industry, announced a call for abstracts for IDEA®, April 29-May 1, 2025, Miami Beach Convention Center, Miami Beach, Florida. IDEA attracts thousands of nonwoven professionals from all functional areas spanning the entire supply chain. The deadline to submit abstracts is Friday, June 7, 2024.

The theme for IDEA25 is “Nonwovens for a Healthier Planet” highlighting nonwoven advancements in sustainability. Abstracts are being accepted via the INDA website: https://www.inda.org/idea25-call-for-presentations/

Product developers, designers, engineers, technical scouts, and marketing professionals accountable for their product’s environmental impact will attend IDEA. Presentations will focus on responsible sourcing, innovations in sustainability, and end-of-life solutions for nonwovens and its related industries.

A few examples of topics for consideration are:

RESPONSIBLE SOURCING

- Natural Fibers (Cotton, Hemp, Bamboo, Banana, Wood Pulp, Regenerated Cellulose, Wool, Fur, Chitin, Feathers)

- Polymers (Biopolymers, Regenerated and Recycled polymers, Unconventional and Alternatives to Traditional Polymers)

- Sustainable Chemistries (finishes, lubricants, adhesives, and additives)

INNOVATIONS IN SUSTAINABILLITY

- Process Improvements with Sustainability Impact (reduced waste, reduced energy, reduced water consumption)

- Product Design Improvements with Sustainability Impact (lightweighting, designs for end-of-life, “good enough” design)

END-OF-LIFE SOLUTIONS

- End-of-Life or Next-Life Considerations (compostability, biodegradability, recycling, advanced recycling and circularity)

Presenting is an opportunity for technical professionals to showcase pioneering research, innovative solutions, and expert insights with technology scouts. Abstracts must be submitted via the INDA website by June 7, 2024: https://www.inda.org/idea25-call-for-presentations/

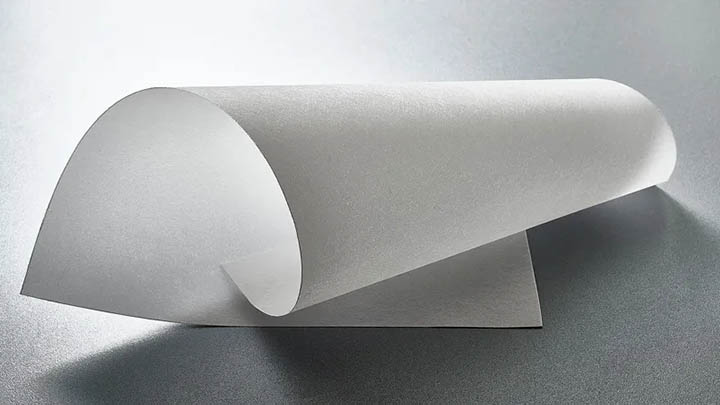

Freudenberg Launches Fully Synthetic Wetlaid Nonwovens for Filtration

Freudenberg Performance Materials has unveiled a new 100 percent synthetic wetlaid nonwoven product line made in Germany. The new materials can be manufactured from various types of polymer-based fibers, including ultra-fine micro-fibers. These unique wetlaid materials from Freudenberg are designed for use in filtration applications as well as other industrial applications. This product line rounds off the wide range of wetlaid nonwoven capabilities from the leading manufacturer of high-performance materials.

Customers in the filtration business can use Freudenberg’s new fully synthetic wetlaid nonwovens in both liquid and air filtration. Applications include reverse osmosis membrane support, support for nanofibers or PTFE membranes as well as oil filtration media. The new materials are suited to use in the building & construction industry or the composites industry.

Leigh Fibers Purchases Martex Fibers

Leigh Fibers’ owners have purchased the operating assets of Martex Fiber and rebranded the business as Revive Fiber.

Leigh Fibers and Revive Fiber will operate as separate but related sister companies under joint management as the largest textile recycler in North America.

With multiple production facilities in South Carolina and one in Brownsville, Texas, this investment expands capacity to meet growing production needs. All products will continue to be made in the U.S. while supporting industries throughout North America, South America and Europe.

“The acquisition of these assets will benefit customers of both companies. While the companies will remain separate, we have broadened and deepened our resources, improving our capabilities and expertise. Nobody else can provide the same breadth of products from recycled fibers, eco-friendly chemistry, toll manufacturing, and nonwoven solutions,” said Daniel Mason, co-owner of Leigh Fibers and the newly formed Revive Fiber.

The two companies provide a seamless solution for textile recycling, from high-volume to specialty custom fibers, across industries including automotive, apparel, bedding and acoustic insulation. A greater raw material base and production capacity will expand sourcing options for customers seeking quality recycled fibers.

Kimberly-Clark Introduces Hybrid Style Diaper in Brazil

Kimberly-Clark launched a hybrid style diaper in Brazil through the Huggies Eco Protect brand. The product includes a reusable diaper in adjustable sizes from small to extra-large, and is made from 100% washable fabric, as well as a disposable absorbent pad. When used together, the product reduces the volume of waste discarded in the environment by up to 28%, according to the company.

The Huggies Eco Protect line also features diapers with soft, plant-based materials, reducing the use of virgin plastic and using natural fibers with up to 12 hours of absorption.

Drylock Technologies Establishes Production Site in North Carolina

Drylock Technologies, a leading manufacturer of hygiene products, will create 113 new jobs in Rockingham County, North Carolina.

The company will invest $26.9 million, with the help of a $300,000 performance-based grant from the One North Carolina Fund, to establish its first U.S. production site for baby care in the city of Reidsville.

Based in Belgium, Drylock Technologies has produced private-label absorbent baby, feminine and adult care hygiene products for more than a decade with nine plants and 3,750 employees globally.