Crescoating Infuses Textiles with Antimicrobial Properties That Don’t Wash Out

The paradox of hospitalization is that the very places patients go to improve their health can make them sick. Healthcare-associated infections (HAIs) are a major public health threat in the United States, with one in 31 patients getting infected during or after receiving treatment in hospitals. A new Crescoating technology creates self-disinfecting fabrics that are as safe for the environment as they are for people, holding the promise of significantly reducing HAIs, which could save many lives and billions of dollars annually.

COVID-19 Worsened HAIs

Hospitals are full of textiles – uniforms, patient gowns, bedding, carpet, furniture, towels, curtains – all harboring microorganisms and facilitating the spread of HAIs, including COVID-19. More than one million U.S. healthcare workers contracted COVID-19 as of March 18, 2022, the Centers for Disease Control and Prevention (CDC) reported.

Cleaning and disinfectants prove insufficient in preventing contagion, with a study finding that a newly cleaned uniform had similar rates of bacterial contamination after an eight-hour shift as infrequently washed physicians’ white coats.

The COVID-19 pandemic contributed to a rise in HAIs. For example, central line-associated bloodstream infection (CLABSI), catheter-associated urinary tract infections (CAUTI) and ventilator-associated pneumonia increased by 47 percent, 19 percent and 45 percent, respectively, in 2020. In addition, the CDC also reported that infections associated with methicillin-resistant Staphylococcus aureus (MRSA) increased in 2020.

This is particularly troublesome for nursing homes, where some of the leading causes of deaths are respiratory infections, urinary tract infections (UTIs), gastroenteritis, sepsis and skin diseases, which involve drug-resistant pathogens. These hot spots for life-threatening infections need better protection for residents and workers.

Silver Nanoparticles Are Toxic, Do Not Last

The textile industry has had a growing interest in silver nanoparticles because of their antimicrobial properties. The silver market share of antimicrobial textiles increased from 9 percent in 2004 to 25 percent in 2011, progressively replacing synthetic organic compounds. The most common methods of incorporating metal and metal-oxide nanoparticles into textiles include spraying of a nanoparticle solution, layer-by-layer deposition with polymers or polyelectrolytes, sonochemical coating, plasma deposition and electrospinning.

The problem is these surface coatings are subject to leaching, with silver nanoparticle emission as high as 80 percent during the first wash. In addition, silver has demonstrated toxicity in environmental systems and disruption of biological treatment processes in municipal and industrial water treatment facilities.

Zinc Does Not Harm Human or Environmental Health

Metal nanoparticle-coated textiles have been proven to possess antimicrobial properties but have not been widely adopted by healthcare facilities due to the loss of functionality and environmental pollution from leaching. Yet zinc nanocomposite textiles don’t have such downsides. They are hypoallergenic, nontoxic, maintain their antimicrobial properties for the life of the fabric and do not require high-capital investments for their manufacture.

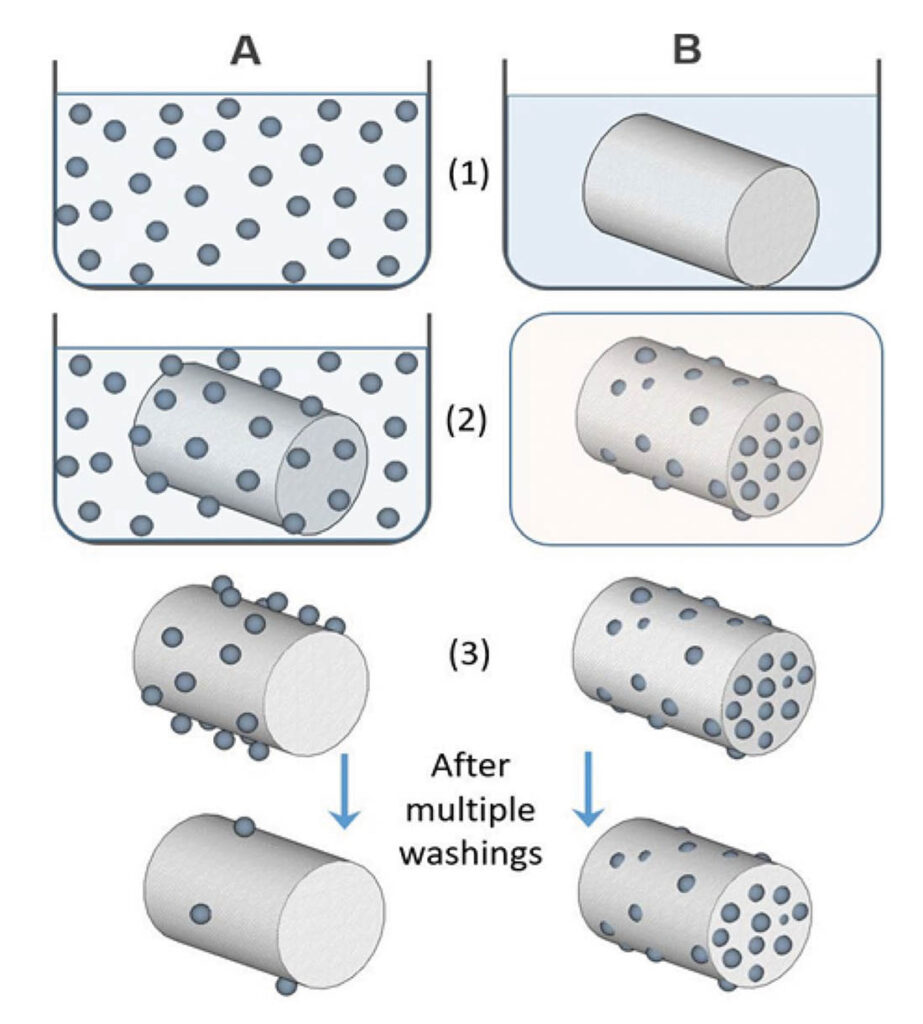

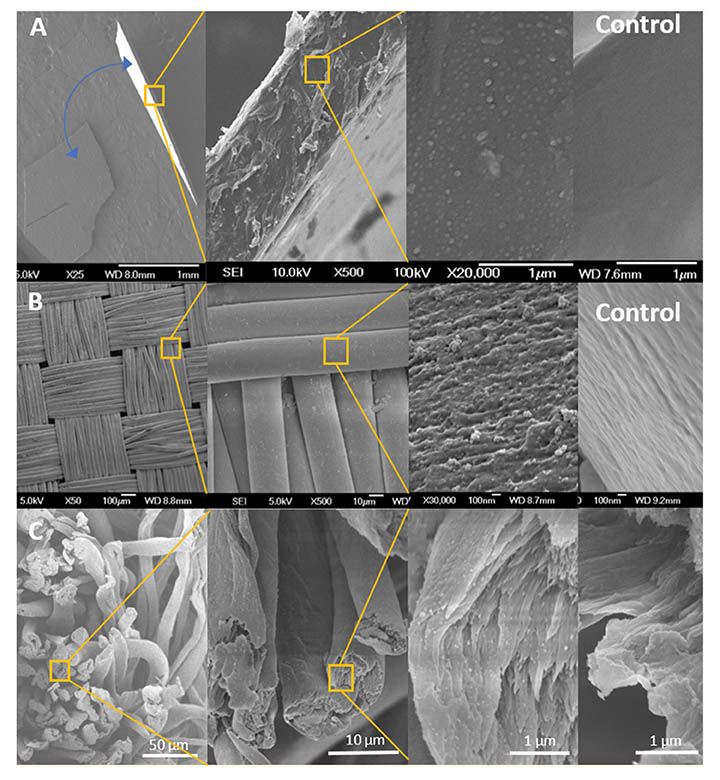

This is all made possible by a new Crescoating (Figure 1) process that was developed and incubated at the University of Minnesota in which zinc nanoparticles are grown directly on and within the bulk of polymeric materials to form safe and durable nanocomposites (Figure 2). The zinc nanocomposite textiles show unprecedented nanoparticle retention that remains intact even after 100 laundry cycles. That means there is no loss in antimicrobial performance and nanoparticles are not emitted into effluent. Another benefit of Crescoating is that it has been shown to work equally well with natural and synthetic textiles (Figure 1).

Metals have been shown to have strong antimicrobial properties. In this case, zinc was chosen because it is Generally Recognized as Safe (GRAS) by the U.S. Food and Drug Administration (FDA) and is commonly used in commercial products ranging from food to cosmetics. Zinc is considered an eco-friendly choice because it does not harm human or environmental health.

Why zinc nanoparticles are so effective in fighting dangerous microbes has not been clearly studied. However, previous studies suggest that their photocatalytic properties generate hydrogen peroxide, which penetrates the membranes of microbes and kills them. There have been fewer studies on the antimicrobial efficacy of these textiles on fungal pathogens. However, the test results indicate that these novel nanocomposite textiles are also highly effective in antifungal applications.

The Simplicity of Crescoating Belies Its Durability

Claros Technologies’ proprietary Crescoating technology is highly versatile. The process can be adapted to various fabrics, including silk, synthetic polyester, nylon-cotton and polyester-cotton blends. The first step is soaking the textiles in an aqueous ionic precursor solution of zinc salt for 30 minutes at room temperature. They are then heated in a convection oven at 100 degrees Celsius for four hours to evaporate water and spur seed formation and nucleation of the nanoparticles. The size of the particles range from 5 to 500 nanometers (nm). Unbound precipitate is washed away by following the American Association of Textile Chemists and Colorists (AATCC) LP1: Home Laundering method.

Crescoating improves the durability and longevity of the nanocomposite textiles compared with conventional surface-coated products, which lose their nanoparticles over time from washing.

Testing Finds Nearly 100% Antimicrobial Effectiveness

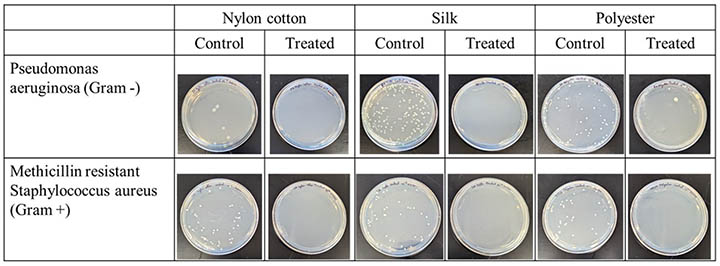

The AATCC’s Test Method 100–2004 was used to test the antibacterial and antifungal properties of polyester, silk and nylon/cotton (50:50) textile swatches obtained from Testfabrics Inc. and Rockywoods Fabrics, LLC, all of which had undergone the Crescoating process.

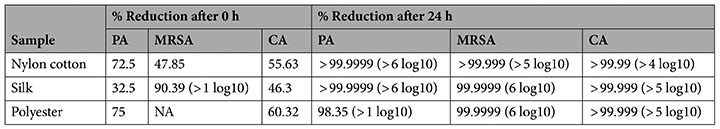

The results have been separated into two categories: a “before washing” test conducted on swatches that have been machine washed soon after treatment and an “after washing” test with swatches that were subjected to more laundering cycles by a third-party testing company. The fabric used was nylon-cotton blend and the tests were conducted on the bacterial species Staphylococcus aureus (MRSA) (Gram-positive) and Klebsiella pneumoniae (Gram-negative) and the fungal species Candida albicans.

“Before washing” antimicrobial test. The fabric samples were inoculated with suspensions of bacteria in nutrient broth and rinsed. One set of samples had no incubation period and another set had a 24-hour incubation period. The eluted solution from the inoculated fabrics was then plated and incubated for 24 hours at 37 degrees Celsius. Bacterial growth was quantified through colony counting on plates (Figure 3).

The same procedure was followed for tests using Candida albicans. Although AATCC recommended antifungal tests for textiles differ from that of bacteria, the growth cycle of Candida albicans resembles that of bacteria, which enables antifungal testing using this modified version of the AATCC Test Method 100–2004.

The best and most consistent results were found with the samples that had undergone a 24-hour incubation period. The 24-hour elution results showed significant microbial reduction ranging from 98 percent to greater than 99.999 percent in samples treated with zinc nanocomposite textiles compared with untreated controls. The percentages obtained are higher than or similar to those reported for antimicrobial cotton fabrics using silver nanoparticles and those using siloxane sulfopropylbetaine against Gram-positive S. aureus and Gram-negative bacteria.

“After washing” antibacterial test. Zinc nanocomposite polyester-cotton fabric was then machine washed 50 times per AATCC Home Laundering method and the antibacterial properties were assessed by Vartest Laboratories, LLC. The nanocomposite textile exhibited more than 99.999% bacterial reduction for both Klebsiella pneumoniae and Staphylococcus aureus after 24-hour incubation (Table 1) even after 50 laundering cycles.

Crescoating technology is a promising process to manufacture zinc nanocomposite textiles that kill more than 99.999 percent of bacteria and fungi.

Third-party Testing Verifies Unmatched Durability

A third-party testing company, Pace Analytical, LLC, tested the retention of zinc nanoparticles in the textiles after several wash cycles. Samples of several types of nanocomposite cotton fabrics were subjected to the synthetic precipitation leachate procedure (SPLP). These fabrics were washed once after manufacturing to remove loose nanoparticles from their surface. The study found that the highest zinc leaching of 106,000 microgram per liter (μg/L) occurs after the first post-fabrication wash for one of the cotton types. Subsequent testing based on the EPA 3010A preparation and EPA 6010B analytical method was then applied to study the leaching of zinc nanoparticles from the fabrics. The results show significantly lower leaching after every subsequent wash cycle.

The tests prove that the nanocomposite fabrics made using the Crescoating method are highly durable. The highest initial leachate concentration is found to be much lower than 250,000 μg/L, which is the soluble threshold limit concentration (STLC) value for California, the state with the strictest limits. Based on this limit, it can be concluded that the concentration of zinc leaching from the fabrics after each laundering cycle is not significant enough to pose a health or environmental hazard. The different values of leaching observed for the three different cotton types could be a result of differences in their fiber sizes and pretreatment processes.

The Zinc nanocomposite cotton fabric was washed 100 times. These samples were tested against the Gram-positive Staphylococcus aureus bacteria according to AATCC test method 100. The results from the 24-hour elution samples show greater than 99.999 percent reduction – better longevity and durability than any other antimicrobial textiles.

Zinc Nanocomposite Textiles Are Hypoallergenic

Zinc nanocomposite textiles were found to be nontoxic and antimicrobial, but it needed to be determined whether they irritate skin. Evalulabs, LLC, conducted the Human Repeat Insult Patch Test (HRIPT) to determine whether these antimicrobial nanocomposite fabrics were safe to use as clothing. The tests were conducted after obtaining informed consent from 50 human subjects and was carried out under the supervision of a licensed dermatologist. The results prove that the fabrics are nonirritating and hypoallergenic to human skin.

The Future Is Now for Antimicrobial Textiles in Healthcare

Crescoating technology is a promising process to manufacture zinc nanocomposite textiles that kill more than 99.999 percent of bacteria and fungi. These textiles are hypoallergenic and do not lose any antimicrobial functionality over 100 laundering cycles. Equally important, zinc is safe for people and the environment. And the fact that Crescoating does not require high-capital investments means that widespread adoption is feasible. Zinc nanocomposite textiles show tremendous promise for use

in medical settings and nursing homes such as linens and surgical gowns, aiding the fight against HAIs and disease transmission.