Welcome to the world of shredding and compressing – welcome to WEIMA! Our extensive range of size reduction machinery includes single-shaft shredders and four-shaft shredders as well as granulators, briquette presses, and draining and compression machinery. WEIMA manufactures single-shaft shredders and briquette presses for the nonwovens industry, allowing for the re-integration of nonwovens scrap into the production process while managing dangerous dust. This allows operations to increase safety and profitability while decreasing waste.

Adding a WEIMA machine to your operation can save you money in waste disposal costs, personnel, and sometimes even reduce your energy consumption each month. Green technology will reduce your operation’s environmental footprint as well. We offer in-stock machinery as well as custom units that will fit the exact needs of your operation and your application.

For more than 40 years our global operation has been focused on the art of shredding and compressing. We develop and produce in Germany and supply worldwide. Since the foundation of our company in 1986, we have delivered around 37,000 machines. As the world innovates, so do we. Destroy responsibly with WEIMA!

Technology highlights

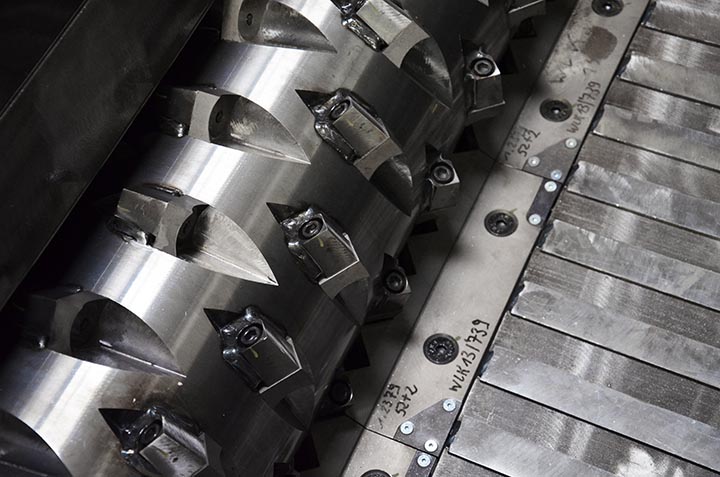

WEIMA’s machinery line for the nonwovens industry is aimed at maximizing your operation’s profits and safety while decreasing mess and excess waste. The WEIMA WLK single-shaft shredder series offers many custom options for the recycling and reintegration of nonwovens, including the F+ rotor, which is ideal for shredding filaments and fibers, as well as a chilled rotor to keep temperatures down during shredding. These shredders can easily be integrated into a nonwovens processing line and can help maximize profits by eliminating the need to purchase virgin materials as often.

The dust particles that are released when nonwovens are cut or shredded can be a burden on manufacturers. This dust can be both messy and extremely dangerous in production environments. Installing a briquette press at the discharge of the dust collection system can help eliminate dusting in the plant and increase overall safety. A dust collection system can pneumatically convey any residual dust into a covered briquette press by using a rotary airlock. This eliminates the need for an employee to spend time cleaning up and transporting the dust and keeps the nearby machinery functioning in a dust-free environment.

Featured benefits

WEIMA takes great pride in supplying the correct machine for the application, and we don’t believe in a one-size-fits-all solution. The systems design engineers at WEIMA will work closely with customers to ensure that the size reduction solution provided is the right one for the job.

- Shredders for reducing nonwovens to a homogenous size

- Chilled rotors available for materials with low melting points

- Compression technology for dust control – safety and health benefits

- Briquette presses can hook into an existing air system for a hands-off dust control process

- WEIMA engineers are always ready to specify the right size reduction system for the job

Handle your scrap where you make it! WEIMA shredders benefit the nonwovens and fiber industries by shredding waste as it is created! Hands-free dust control is made possible by hooking up a briquette press to an existing air system, creating a safe and clean working environment. With 40 years of experience and 37,000 machines sold worldwide, WEIMA has the know-how to provide the correct machine for your unique application.

This content is sponsored by:

Visit us at IDEA: Booth #3711