Reports abound on the issue of textile materials and waste and the implications for the environment. Most companies serving the industry have research and development teams attached to tackling their part in the bigger environmental picture.

This is essentially what led Andrea Ferris and her team to invent CiCLO® technology, which enables polyester and nylon fibers to eventually biodegrade if they unintentionally end up polluting the environment. Inspired by a crisis of conscience as long-time workwear industry professionals, in 2012 the team set out to create a better polyester for their own clients, and then realized it was too beneficial to the environment to keep it from the textiles industry at large.

Over 60% of today’s textiles are made with synthetic fibers: from clothing and carpets to pillows and towels, and more. These synthetic fibers – largely polyester and nylon – are plastics which, when fugitive in the environment, can remain indefinitely because they are not inherently biodegradable.

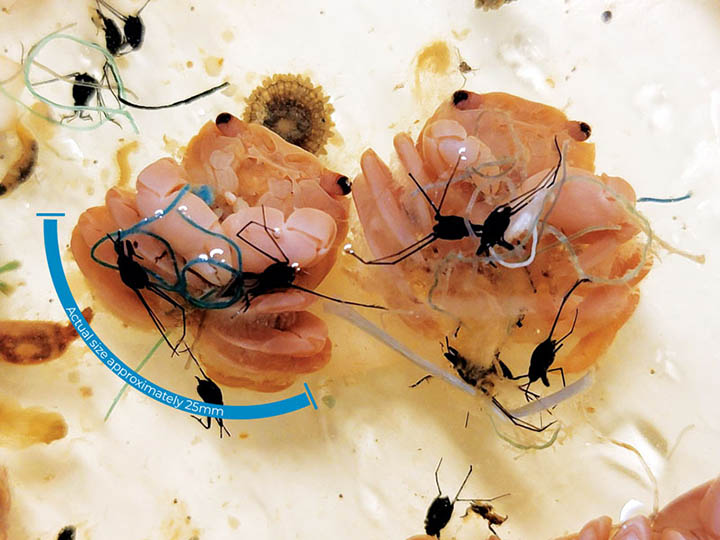

Considering that an average household generates approximately 44 pounds of dust a year, 13 of which consists of microfibers from synthetic clothing, carpets and furniture – the environmental impacts to the Earth can be staggering. In addition to dust, tiny fibers are shed from almost all fabrics during manufacture, use and care. Studies show that microplastics (i.e., particles <1 mm) present in the marine environment may fall into the optimal range of prey size for a wide range of marine organisms and can jeopardize different levels of biological organization, thus representing a potential threat to the conservation of biodiversity and ecosystem function.

After understanding more about the impact of polyester on the planet, they set out to reduce the environmental impact of the workwear they designed and supplied to major brands, and eventually created a whole new company to support commercialization of the technology. While these innovators are generally known as the “CiCLO® team” because the CiCLO® brand has grown to be so well recognized, Intrinsic Advanced Materials (IAM) is the company established in 2018 to scale it. IAM is a joint venture between Intrinsic Textiles Group, a Silicon Valley startup that spun out of a workwear company, and Parkdale Advanced Materials, the innovative fibers and yarns division of Parkdale, Inc., the world leader in the manufacture of spun yarns.

Gaining attention, we caught up with Co-Founder and Co-Inventor, Andrea Ferris, who also serves as CEO of IAM, to discuss the current status of CiCLO’s technology.

International Fiber Journal: Explain the origins of CiCLO® technology.

Andrea Ferris: It’s actually a neat story. The idea for CiCLO® – which didn’t have a name when we first had the idea – emerged over a decade ago in 2012. I was working for a uniforms and branded merchandise company owned by my now business partners, Alan McIntosh and Wayne Beasley, where we offered everything from the design to manufacturing to delivery to customer. It was around that time when research began to emerge on the shedding factor of textiles. The uniforms industry is heavy in polyester, due to its great performance attributes, affordability and availability. Almost all fabrics shed to some extent, and with polyester being plastic, it is shedding plastic into the environment. Once tiny fibers are fugitive in the environment, they cannot be recaptured. This was concerning to us.

We researched to see if there was an off-the-shelf fix for this problem but came up empty handed. However, we learned a lot about the science behind biodegradable plastics on our journey and set out to invent a tailored biodegradable solution specifically for textiles; a technology that allows polyester to maintain the durability and performance characteristics that we choose it for, but that enables it to eventually biodegrade like natural fibers when it winds up in the environment. Sounded really easy at the time! We hired our Chief Scientist and got to work.

After CiCLO® polyester fully bio- degraded in a 3.5 year third party lab study (versus only 6% for conventional polyester), we recognized we’d invented something important for the earth and were compelled to make it available beyond our own clients. We created the CiCLO brand for our newly discovered sustainable textile technology and spun off a separate company to commercialize it.

Because we initially developed it for our own use, we knew which boxes to check in research and development. The end products had to maintain performance and durability. Spinning efficiency had to remain high. Dye processes had to remain unchanged. Chemistry had to be 100% safe for those handling it, and those wearing it. The technology had to last the life of a garment and never wash off.

Yet, the end products shouldn’t persist forever in the environment like conventional polyester.

Research shows that synthetic fibers that shed from textiles are the #1 microplastic source in all environments across the globe.

IFJ: How have you seen the view of microplastics change through the years?

Ferris: In 2012, there was emerging news about the shedding of textiles being identified as a source of microplastic pollution in the form of little fibers, commonly referred to as microfibers. Now, there are textbooks dedicated to the topic of microfiber pollution and more research and news published practically daily. Research shows that synthetic fibers shed from textiles are the #1 form of microplastic pollution in all environments across the globe. Synthetic microfibers account for 35% of the microplastics found in the oceans. Government agencies like the EPA and NOAA, state legislators, NGOs, brands and manufacturers are all researching this massive problem and seeking solutions.

In 2018, The Ellen MacArthur Foundation published The Circular Fibres Initiative, a comprehensive report that calls out many problems within the textiles industry, including pollution caused by synthetic textiles. The authors estimate that the amount of synthetic microfibers entering the oceans annually is equivalent in weight to 50 billion plastic bottles. These very small fibers and hard to see, but they are everywhere and cannot be recaptured once they’re in the environment.

IFJ: Tell us more details about the progression from idea to spinning off a new company.

Ferris: When we started the journey in 2012, we didn’t even know the ‘ins and outs’ of how fiber was made or what conditions were required for materials to biodegrade. We had to learn everything from scratch, which was fun and insightful! We visited compost facilities, landfills, waste water treatment plants and biodegradation testing labs. We hired landfill and marine plastic pollution experts. We wanted to understand the realistic best-case solutions to create biodegradable polyester by considering pollution and end-of-life problems.

In 2016, Intrinsic Textiles Group was spun out of the workwear company, and the technology was launched under the brand name CiCLO® in the summer of 2017. It was also around that time when we met our now joint venture partner, Parkdale Advanced Materials, the innovative fibers and yarns division of Parkdale, Inc., the world leader in the manufacture of spun yarns. Our joint venture creates a wonderful balance of stability and agility. We have this stellar combined team of resources, including R&D, brand protections, marketing, PR, manufacturing, fulfillment, customer service and business development … it is a fantastic partnership.

IFJ: Tell us more about the brand CiCLO.®

Ferris: CiCLO® translates to “cycle” and we chose the word for our brand because CiCLO technology is part of the circular economy. It was very important for us – as we were creating this technology to help plastic biodegrade – that the brand name didn’t imply it fits into the current linear “take-make-waste” economy, or the idea that because it is biodegradable it’s intended to be disposable. The intent of CiCLO technology is to apply it to durable textiles where the use of plastics like polyester and nylon are necessary, and for those products to be utilized for a long time, hopefully recycled someday, then eventually return to basic natural elements when they end up in the environment.

IFJ: What would you like to see people do with these products when they are done with them, like say, a pair of jeans?

Ferris: Repair, reuse, hand down or recycle! We hope to eventually see an infrastructure in place for all textiles to be recycled. CiCLO® polyester and nylon can be mechanically or chemically recycled, just like conventional synthetics.

IFJ: What kind of R&D for biodegradability took place in development of CiCLO®?

Ferris: To test for biodegradability, we contracted with third-party labs around the world, including Intertek and Bureau Veritas, who use internationally recognized ASTM and ISO Test Methods designed to study the biodegradability of plastics in various environments. We compare CiCLO® polyester versus a comparable conventional polyester. The tests are based on “all things equal.”

At what rates do these two things biodegrade if they wind up in the same environmental conditions? We choose Test methods that measure the rate and extent of biodegradation in environments where synthetic microfibers are prolific pollutants, including landfill conditions, soil, wastewater treatment plant sludge and natural sea water.

Microfibers shed from textiles are transient, so it makes sense to test in various environments. For instance, shedding during home laundering is one major pathway that is well established. From a washing machine, they move onto wastewater treatment plants. Studies show that 65% up to 99% of synthetic microfibers can get trapped in wastewater treatment plant sludge. Sludge is often used for landfill cover or as a soil amendment. And since the ocean is downhill from everywhere, huge amounts of synthetic microfibers are polluting the ocean.

IFJ: How many iterations of your formula did you develop before the final one? And how does it now get into the marketplace?

Ferris: During our R&D iterations, we looked at about 15 different formulations, looking for active ingredients that could compound well together, that are safe once compounded into our final product, could spin efficiently, and allow the finished fibers to biodegrade at greatly accelerate rates. We looked at the all these different formulations side-by-side to decide on which are best, based on their performance in various environments, and narrowed it down to our final chemistries. CiCLO® technology is patented around the globe.

We sell the CiCLO® chemistry to our global network of CiCLO® Certified Manufacturers of polyester and nylon fiber and yarn manufacturers. They add CiCLO to conventional or recycled polyester and nylon during melt extrusion.

IFJ: How do you help your customers and brands understand their best use of CiCLO®?

Ferris: We are highly engaged with end brands to help them understand how the product works, how it’s added, safety and efficacy. We regularly advise on the best supply chain partners to get CiCLO® into their products and help with any testing required. It’s also important for retailers and brands to understand how to market products using CiCLO® fibers to end consumers, so we offer responsible marketing guidelines, and our marketing team works closely with customers to support them in whatever capacity is necessary.

As of today, at least 50-60 brands have products with CiCLO® fibers for sale at retail. In development, we are working with hundreds of interested manufacturers and brands.

IFJ: What markets you’re working in?

Ferris: The CiCLO® brand and solution is specific to the textiles industry, and includes everything from apparel, accessories, home textiles, medical textiles, filtration, fiber fill, geotextiles and more. Consider anywhere that polyester and nylon are being used … those are the markets we’re working in today.

Over the last several years we have met with hundreds of brands, and I’ve yet to come across a brand who doesn’t want to do better than they’re doing today. The textiles industry is moving towards much better days and implementing good solutions.

IFJ: What is your vision and mission for the company now?

Ferris: The mission for CiCLO® technology is to make the greatest possible contribution towards mitigating synthetic microfiber pollution in the environment. Our vision for the future is that all synthetics will utilize CiCLO® technology. There’s no excuse for not using CiCLO® technology to manage the unavoidable microplastic pollution caused by synthetic textiles. As a company, IAM is working on sustainable solutions for other sectors beyond textiles, but nothing I can share with you today. You can expect more smart products commercialized in the near future.

IFJ: Do you see the textile industry adopting a circular economy anytime soon?

Ferris: Over the last several years we have met with hundreds of brands, and I’ve yet to come across a brand who doesn’t want to do better than they’re doing today. The textiles industry is moving towards much better days and implementing good solutions. The fact is that for sustainable materials to be adopted, there must be the business case behind it. We could come up with better materials all day long, but if they’re not available globally and affordable, they’re not going to be adopted. As technology and materials inventors, we see it as our job to make products that meet these requirements and can be easily implemented.

IFJ: Do you have any final comments?

Ferris: I hope people understand that microplastic pollution is not just a waste issue. It’s tied into climate change and is a hazard to human health. There is research emerging about how microplastics in the oceans are inhibiting the ocean from doing its job of sequestering carbon from the atmosphere. So all of these combined add up to a very complex problem that is going to require many solutions.

CiCLO® technology is one of these solutions, and we’ve made it easy for manufacturers and brands to adopt.