Diamscope uses the light microscopy method to automatically scan and analyze fibers in water, measuring diameter (from 0.2 µm), curvature and length (less than 0.5 mm). The water helps disperse the fibers evenly and rapidly.

The whole measurement process takes less than two minutes to prepare the sample and measure up to 20,000 fiber snippets. The system is self-cleaning and self-contained, and the water is recycled in the system via three levels of filtration that will ensure minimum contamination.

Diamscope is ideal for measuring glass, ceramic and synthetic microfibers for research and quality control. For fibers with a high standard deviation of diameter Diamscope provides the only fast and accurate way to measure diameter distribution.

Principle of Diamscope

Fibers are prepared using the cutter and dropped into the open bowl with 120 ml of distilled or deionized water, where a magnetic stirrer is employed to disperse the fibers.

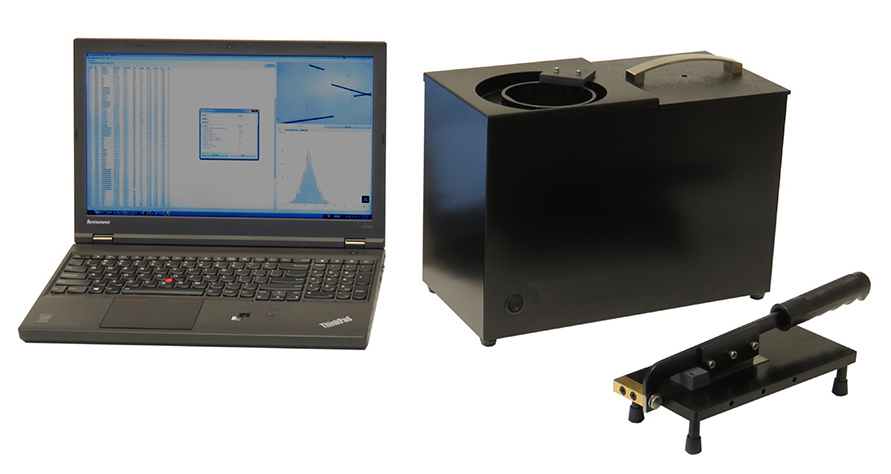

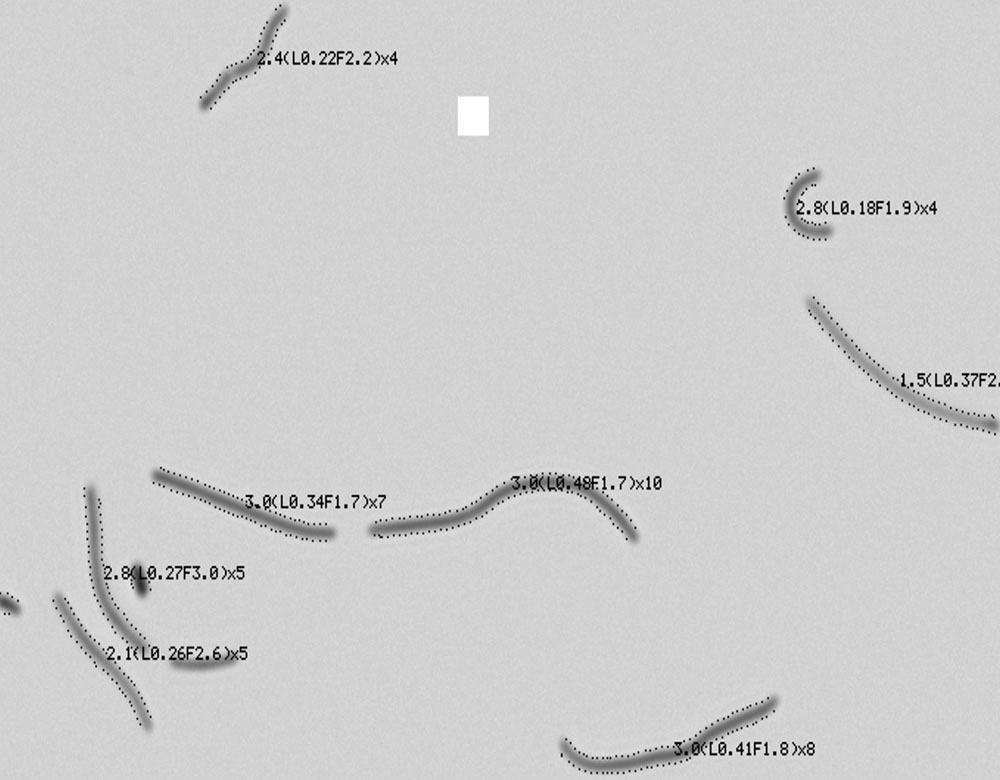

The individual fibers then pass through a gap between a right-angled prism and a glass window, where high-resolution images of the fibers are digitized using light from a strobed light-emitting diode (LED) source and customized optics. The specialized software analyzes and measures each image in less than 10 ms (Figure 1).

A proprietary sub-pixel algorithm developed in 1990, which is also used in all Optical-based Fibre Diameter Analyser (OFDA) products, is essential to the accurate measurement of diameter over a wide range of focus and light levels. The OFDA instruments are an established standard for the measurement of fiber diameter and the textile industry.

Key Benefits

The main advantage of Diamscope over other diameter measurement systems such as airflow, manual microscope and scanning electron microscope (SEM) is the ability to measure thousands of fibers in a short amount of time, giving a more accurate mean and distribution.

Distribution is a key factor in fiber performance and can only be accurately represented with a sufficient number of measurements (thousands, not hundreds).

Some glass and ceramic wool fibers produce multiple peaks in the distribution.This is caused by the spinner type and age and is a good indicator of spinner wear.

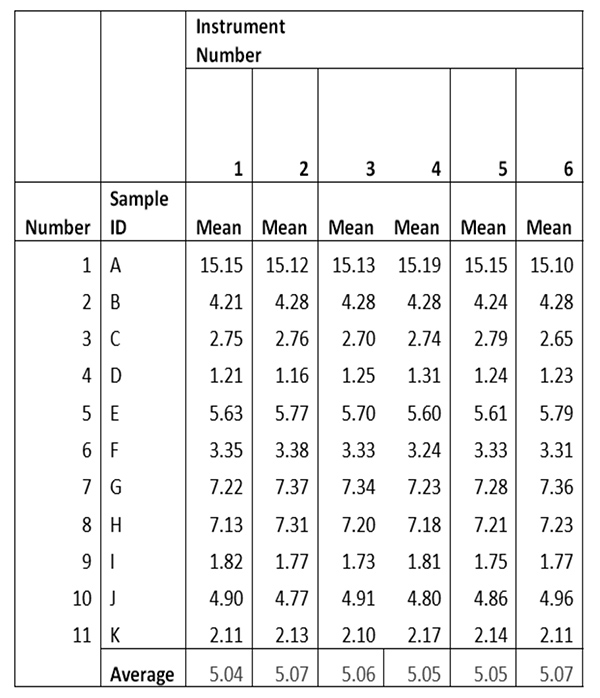

Diamscope measures fiber diameter from 0.2–150 µm using a single calibration without the need to change the lens. The solid-state light source and uniquely designed measurement system means there are no blockages and require minimal maintenance, and Diamscope has good reproducibility (Figure 2).

Fibers are suspended in water while being measured, which eliminates the common problem of broad-side biased measurements with microscope slide systems. (Fibers lying on a microscope slide tend to lie on their broad side.)

Fiber preparation is quick, easy and superfine fibers are not lost. When the fibers are cut on the Diamscope cutter, the superfine fibers are held together with all the other fibers and dispersed quickly when placed in the water. Other methods that depend on gravity for the fibers to fall on the glass slide will lose a lot of the superfine fibers as they are lost floating off into the air.

There is no operator bias in the measurement; with manual systems the operator often skips fused and damaged fibers to measure. Operators can be trained quickly to use the Diamscope system, unlike other systems that require long training and experience.

Diamscope has a small footprint and also does not need the samples to be dried before measurement.

Fiber Curve Measurement

At present, curve measurement in glass fibers is new and the subject of research since a high-speed curve measurement

device has not been previously available. However, a number of papers are available from BSC Electronics that discuss OFDA curvature measurement of sheep wool.

Fiber curvature is the measurement of the degree of bend of the fiber snippet in degrees per mm. Mean values range from 1°/mm to more than 100°/mm. Fiber curvature has a good correlation with bulk and therefore can predict insulation and compression recovery properties.

Fiber Diameter Distribution

Fiber diameter distribution is the histogram of diameter of the individual fibers in a sample. For most animal fibers, cotton and synthetic fibers the histogram is stored in a 1 µm bin size. To allow more accurate histograms of ultrafine fibers, Diamscope stores diameters in a bin size of 0.2 µm. The premium segment of the textile industry has moved away from using airflow measurement, which does not provide diameter distribution.

Using glass fiber for filtration, Bauer states that diameter distribution contributes appreciably to media performance properties, most notably filtration efficiency and pressure drop.

Fiber samples with the same mean diameter can behave very differently with different diameter distributions. For example, 1 m of yarn with a mean diameter of 10 µm and a standard deviation (SD) of 4 µm will weigh 11.5% more than 1 m of yarn with the same mean diameter and a SD of 2.

Diamscope has been developed by BSC Electronics, a supplier of wool and cashmere fiber measurement instruments (OFDA) used in more than 30 countries.

BSC has been designing and manufacturing fiber measurement instruments for over two decades using the latest digital video technology.

For more information contact:

Cottonscope Pty. Ltd.

Tel:+61 8 9316 9499

Email:info@diamscope.com

Website:www.diamscope.com