Shafiq Islam developed a strong interest in textiles pursuing his undergraduate and master’s degrees in textile engineering in Bangladesh, while also working in the textile research and development sector.

3rd Year Ph.D. Student

University of Georgia

Department of Textiles, Merchandising, and Interiors

Nonwoven Functional Materials Lab

Professor/Advisor: Gajanan S. Bhat, Ph.D.

As an undergraduate, Shafiq’s main interest was technical textiles, nonwovens, and composites, and this is also the focus of his Ph.D. research at the University of Georgia (UGA).

UGA, founded in 1785, is one of the oldest public universities in the United States. This university is classified as R1 doctoral university, and the department of Textiles, Merchandising, and Interiors is one of the few remaining textile programs in the United States. The program provides the opportunity to research in diverse areas including nonwovens, composites, biomaterials, nanotechnology, smart textiles, sustainability and consumer satisfaction.

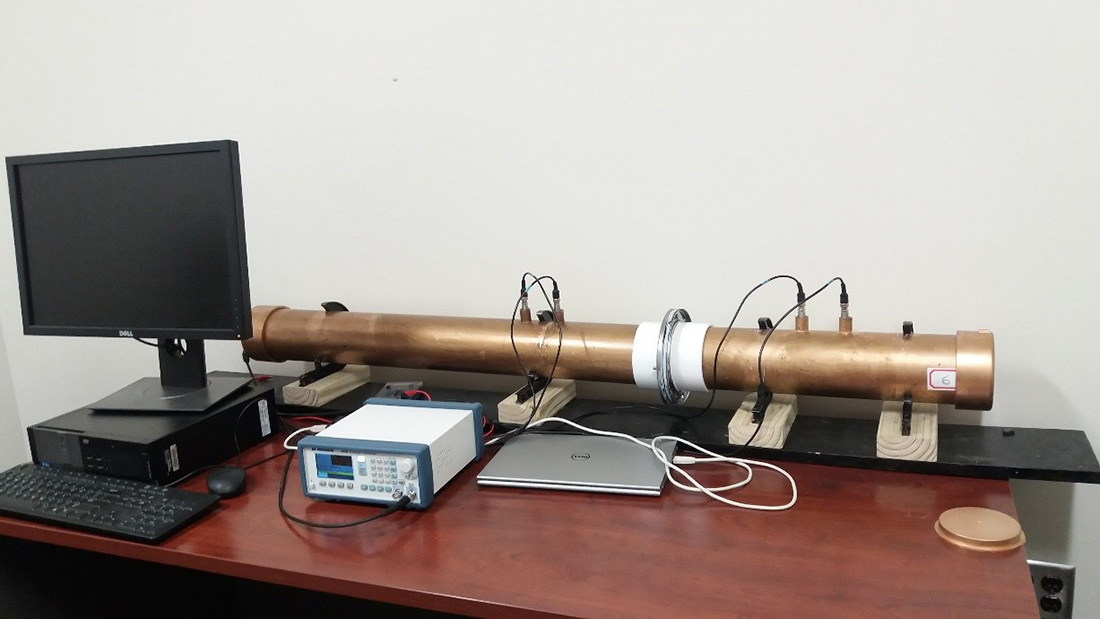

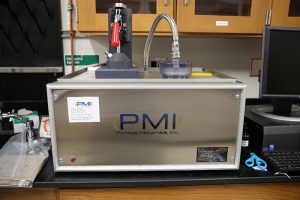

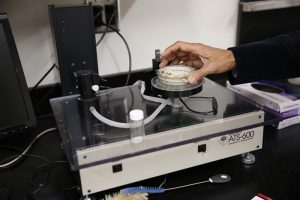

The Nonwoven Functional Materials Laboratory in this department, under the supervision of Gajanan Bhat, Ph.D., has several unique facilities to fabricate and characterize nonwoven-based products.

Research overview

Shafiq’s main research interests are the design and development of composite materials, and production of environmentally friendly, sustainable insulation materials from recycled textiles. Shafiq, working with industrial partners, has successfully demonstrated that recycled post-consumer textile waste can be converted to commercially feasible sustainable composite materials for the application of thermal and acoustic insulation by using nonwoven fabrication techniques.

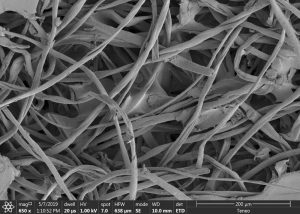

Shafiq is currently evaluating nonwoven-based insulation materials from recycled denim fabrics. For the preparation of insulation materials, waste denim fabrics were converted into fibers, and then mixed with a compostable thermoplastic binder fiber at different ratios.

Commercially available polylactic acid (PLA) and Sorona® were investigated as possible binder fibers. Fibers were mixed at different ratios and intimately blended nonwoven webs were produced using a laboratory card. The carded webs were hot pressed at different temperatures and pressures to produce composite panels for further evaluation.

Shafiq is evaluating the micro structure of the panels, as well as their thermal and acoustical insulation properties. These composites have shown much higher insulation properties than those that are currently commercially available.

Shafiq is also working on lifecycle assessment (LCA) of produced insulation materials and comparing them with those of commercially available products. Another desirable property of such composites is that of self-repairing. At present, Shafiq is investigating the possibility of incorporating the right ingredients to make self-healing composite materials.

Shafiq, working with industrial partners, has successfully demonstrated that recycled post-consumer textile waste can be converted to commercially feasible sustainable composite materials for the application of thermal and acoustic insulation by using nonwoven fabrication techniques.

Career goals

At present, Shafiq’s main target is to complete his Ph.D. degree within the next year. He has already published one paper and has submitted another research paper. His target is to conduct high-quality research in product development with in-depth fundamental understanding, and disseminate the findings of his research in a timely manner.

In the future, Shafiq’s interest is to continue his research in the areas of nonwovens and other textile materials. He also has an interest in teaching. Therefore, Shafiq wants to be a university professor actively involved in both education and research. In the next 10 years, he aims to establish himself as a leading researcher in the areas of fiber science and sustainable materials.