JOA designs converting equipment and specialized technologies for many categories of disposable, absorbent hygiene, medical and specialty products. Our state-of-the-art machine platforms—backed by 24/7 global support—are recognized for speed, quality and innovation.

Innovative converting solutions

Working with hundreds of clients worldwide, JOA solves some of the most intriguing production challenges for a variety of nonwoven products:

- Adult incontinence (pants, briefs, light incontinence)

- Baby diapers and pants

- Feminine hygiene

- Food pads

- Medical

- Face masks

- Specialty-purpose

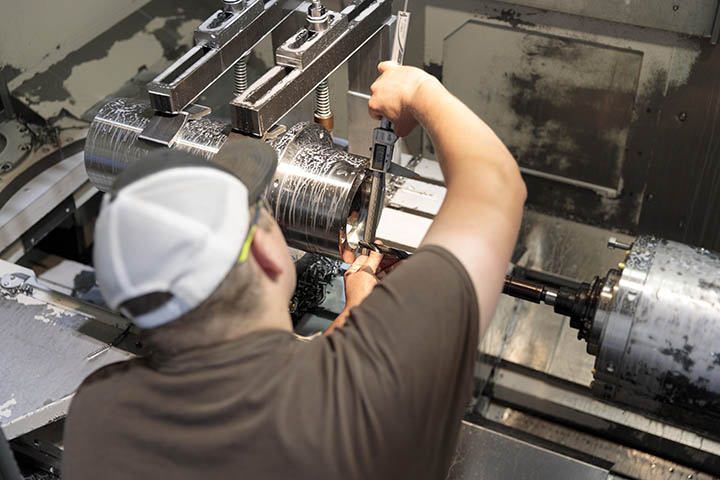

Unsurpassed process control

With critical machining, manufacturing and all assembly operations on-site, JOA maintains complete quality and process control. And with engineering teams dedicated to enhancing each platform, combined with expertise in a wide range of manufacturing processes, we help deliver what your consumers want—now and in the future.

Leverage decades of engineering expertise

Our engineers are dedicated to developing innovative manufacturing solutions. Bring us your ideas and we’ll make them a reality. We use proven process methodology and state-of-the-art instrumentation to solve the converting industry’s toughest product or process challenges. We can evaluate existing machines regardless of the original manufacturer and make recommendations for upgrades or modifications.

From designing custom solutions for unique products to delivering personalized support, JOA meets the most demanding requirements. Routine and emergency replacement parts can often be manufactured and shipped same day for both late model and legacy machines. Trust our close collaboration, from design through delivery, to deliver the optimal solution.

Upgrades and retrofits revitalize older machines

Give new capabilities to your legacy equipment, quickly and efficiently. Our upgrade kits integrate with virtually any machine—regardless of the original manufacturer. Our expert technicians evaluate your machine and recommend upgrades or modifications that reduce material waste, improve production speed and quality, automate time-consuming tasks and more.

Proven methodology

Since introducing automation to the disposable hygiene industry in 1932, JOA has perfected a system for developing repeatable, high-precision manufacturing processes. To ensure success, we deploy teams of six-sigma black-belt engineers in conjunction with Failure Mode Effect Analysis (FMEA) to mitigate customer risk.

Fast and secure machine assembly

Highly skilled JOA professionals assemble machines meticulously and on schedule. With our modular frame design, installation time and cost are minimized. In addition, our technicians perform a thorough cross-check after assembly, ensuring quick startup upon machine delivery. Private, enclosed assembly bays, on- and off-site, guard the confidentiality of your project at every step.

Personal and responsive support

We’re invested in your business and work to build relationships that last. Get 24/7 access to problem-solving professionals and on-site technical support at a moment’s notice. JOA technicians do whatever it takes to keep your machines up and running.

Visit us at INDEX: Booth #2551

This content is sponsored by JOA.