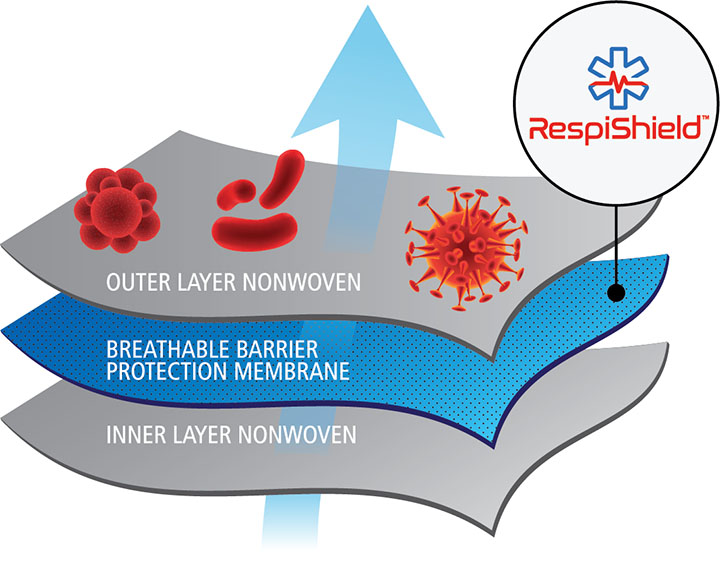

Celgard has long delivered highly engineered products with proven quality and performance. The new RespiShield™ membrane leverages the company’s technical capabilities and the unique polyolefin molecular properties created by its patented manufacturing process.

The key to the performance of RespiShield™ membranes is found in its pores – their shape, their size, their uniformity, and the polyolefin materials they are made from. The result is a one-of-a-kind membrane that offers an optimal combination of viral protection, breathability and lightweight properties.

Viral and other barrier protection

Healthcare workers use PPE, such as surgical and non-surgical gowns and drapes, to protect both patients and themselves from the transfer of viruses and other microorganisms by blood and other biological fluids. Industry standards classify a gown’s ability to act as a barrier to penetration by liquids or liquid-borne pathogens into four levels.

- Level 1: Minimal Risk (ex: during basic care, as a cover gown for visitors)

- Level 2: Low Risk (ex: during blood draws, suturing, taking care of ICU patients, pathology lab)

- Level 3: Moderate Risk (ex: when inserting IV lines, taking care of Emergency Room patients or with trauma cases)

- Level 4: High Risk (ex: during surgery, when pathogen resistance is needed, when infectious diseases are suspected)

Certified third-party testing has shown that all RespiShield™ membranes achieve Level 3 blood barrier protection with some RespiShield™ membranes achieving Level 4 viral protection.*

The product’s ability to act as a barrier to blood-borne pathogens is twofold. The manufacturing process used to produce RespiShield™ membranes creates a product that is naturally hydrophobic, or liquid resistant. Additionally, the unique pore size and pore distribution within the membrane contribute to the creation of an excellent blood and/or virus barrier.

Breathable, lightweight & quiet

Celgard® RespiShield™ membranes have a porosity of more than 50% – meaning that they consist of more air than material. This high porosity allows for excellent airflow and moisture evaporation, making these membranes some of the most breathable on the market.

RespiShield™ membranes are also remarkably light. With a thickness of only 12-18 microns, they weigh in at less than 6 grams per square meter.

The thin, airy structure combined with polyolefin material properties also result in a quiet product.

Eco-friendly

Celgard® RespiShield™ membranes are produced using a solvent-free manufacturing process with a low carbon footprint. The polypropylene-based material is recyclable and completely perfluorocarbons (PFCs) free.

*All RespiShield™ membranes achieve synthetic blood protection (ASTM F1670) and some membranes achieve viral protection (ASTM F1671) per the CDC ANSI/AAMI PB70 standard in preliminary testing.

This content is sponsored by: