Lauren Taylor and Oliver Dewey are pursuing doctorate degrees in Chemical and Biomolecular Engineering at Rice University where they study the processing of carbon nanotubes (CNTs) into high-performance fiber. Lauren’s research interests also include purification of CNTs for dissolution into chlorosulfonic acid (CSA) and application of CNT fibers for wearable textiles. She became interested in this field by her mother who taught her how to sew at a young age. When she was introduced to CNT fiber, she immediately saw that it could be sewn into fabrics to make wearable electronics, an entirely new area for the cf2 Group.

CNT fibers are on track to be the strongest synthetic fiber by the end of the decade. The fibers have exceptional properties due to the large aspect ratio (length of the CNT to diameter) of the constituent CNTs, high degree of alignment of the CNTs, and good packing density of the fibers.

Oliver learned fiber spinning early in his Ph. D, and he became especially interested in understanding the processes of fiber formation at the spinneret. He added inline microscopy capabilities to the spinning system to study the underlying mechanisms of coagulation, elongation, and breakage closely. He also built custom rheological equipment to characterize the superacid CNT solutions to better understand and optimize their processing.

7th Year Ph.D. Student

Rice University

Chemical and Biomolecular Engineering

6th Year Ph.D. Student

Rice University

Chemical and Biomolecular Engineering

Research overview

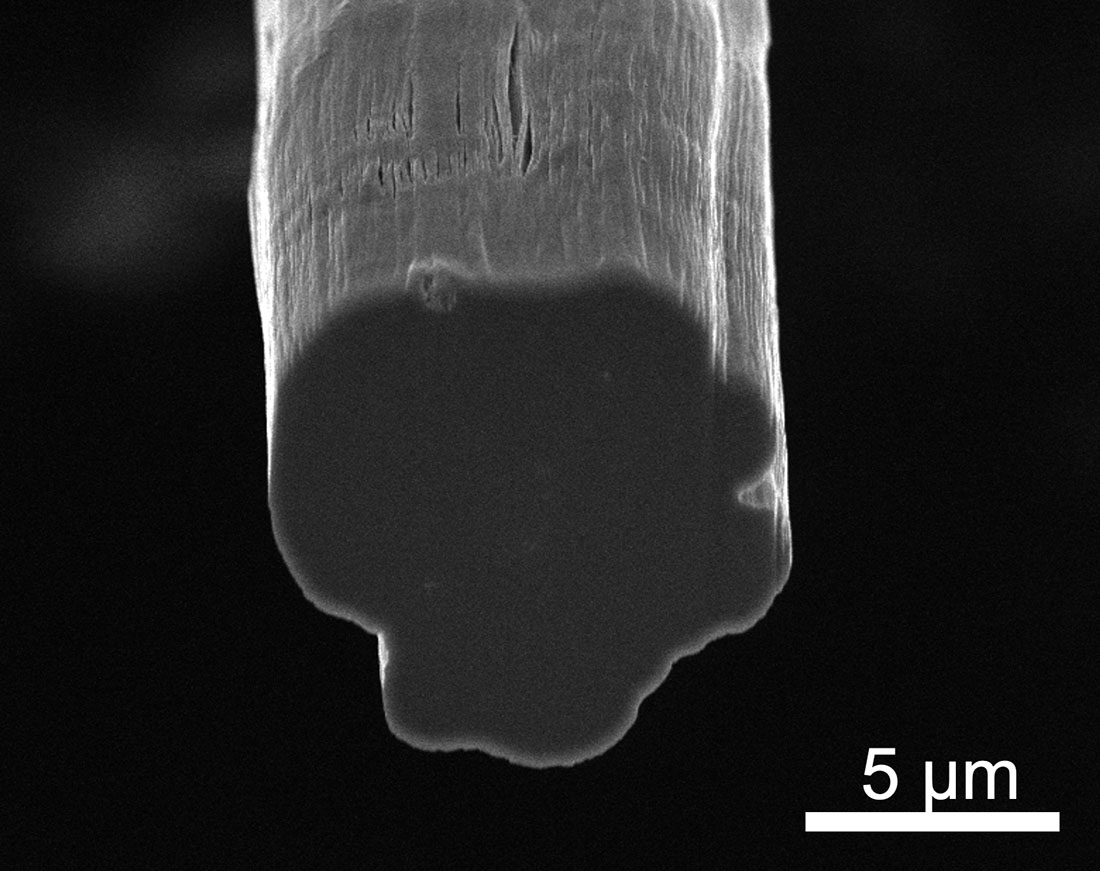

Lauren and Oliver have collaborated for four years on the production and characterization of high-performance CNT fibers. In their research, CNT fibers are produced through solution spinning. First, CNTs are dissolved into CSA to form a liquid crystalline solution. The solution is extruded into a coagulation bath of acetone where the acid diffuses away from the liquid filament and the CNTs hold together via strong Van der Waals forces. The solid fiber is then collected onto a rotating drum for characterization.

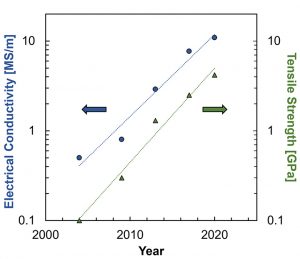

Their research efforts have developed significant improvements in the performance of neat CNT fibers. In their recent publication in Carbon, Lauren and Oliver report fibers with a tensile strength of 4.2 GPa, a Young’s modulus of 260 GPa, an electrical conductivity of 10.9 MS/m, and a thermal conductivity of 390 W/m K. These latest results continue an impressive trend for solution spun CNT fibers; electrical conductivity and ultimate tensile strength are essentially doubling every three years.

CNT fibers are on track to be the strongest synthetic fiber by the end of the decade. The fibers have exceptional properties due to the large aspect ratio (length of the CNT to diameter) of the constituent CNTs, high degree of alignment of the CNTs, and good packing density of the fibers. Interestingly, Lauren and Oliver highlighted that the enhanced properties uniquely position CNT fiber for adoption in numerous real-world applications, as no other material has the combination of conductivity, strength, and flexibility. These applications include biomedical devices, electronic fabrics, ballistic protection, and next generation wiring and cables.

Career goals

Lauren is about to defend her thesis and is excited to continue her academic journey as a Postdoctoral Fellow at the Princeton Center for Complex Materials. After completion of her postdoctoral studies, she would like to become a professor and study multifunctional fabrics. Lauren is passionate about supporting other women in STEM. She aims to help foster diversity in engineering by being a strong mentor for her students and volunteering for outreach programs for grade school children.

Oliver is focused on collecting the final data for the various projects that make up his thesis, with the aim of defending by the end of the year. He is beginning his hunt for a postdoctoral appointment at a university or national lab with the ultimate goal of becoming a professor. Oliver is particularly interested in working to mitigate climate change and improve environmental sustainability of human activities. He hopes to continue research after Rice in renewable energy and hopes to share his passion for sustainability through future outreach work.

As professors, Lauren and Oliver look forward to meeting up at conferences to discuss their latest research and reminisce about their time in graduate school together.