The use of technical textiles is quietly expanding in the US$850 billion global packaging market – an industry that is on the verge of a transformation with the arrival of new technologies and innovative and sustainable materials.

The packaging industry involves goods or products that are contained, carried, stored and/or protected. The sector includes flexible packaging materials made of textiles used for various industrial, agricultural and consumer products.

Packaging is estimated to account for around 15% by volume of the global technical textiles market. Textile packaging materials range from polymer-based bags for industrial packing to jute sacks for packaging grain and tea, and from heavyweight woven bags and sacks to lightweight nonwovens used to wrap food and industrial products.

Rise of polypropylene

Sacks and bags were traditionally manufactured from cotton, flax and jute, but increasingly they are made from polypropylene.

In the modern packaging market, especially in the food industry, lighter weight nonwovens and knitted structures are now being used for a variety of wrapping and protection applications, while tea and coffee bags are typically based on wetlaid nonwovens.

Meanwhile, vegetables, meat and fruit are frequently packed with a nonwoven insert to absorb liquids, while fruit and vegetable products that are sold loose are often supplied in knitted net packaging.

Producers of packaging textiles are now seeing growing environmental pressures for disposable and/or biodegradable materials that can be reused or recycled. Such demands are also likely to lead to a move away from less durable materials, such as paper, towards highly engineered nonwovens for packaging consumer products.

Nonwovens in particular are likely to benefit: the lightweight properties of materials such as wetlaid and spunbond nonwovens are increasingly being used in the food industry and for packaging medicines and electronic parts.

Market trends

Population growth and urbanization – and the rise of online trade and e-commerce – are increasing the trade in, and the use of, packaging. Products are also being consumed on the go, thereby increasing the need for food service packaging and different sizes of packaging.

According to Smithers Pira, the total global packaging market will continue to grow steadily at around 3.5% a year, reaching US$980 billion in 2022.

Paperboard packaging, of which 50% is made from virgin fiber, accounts for around US$300 billion a year, with an average annual growth rate of 3%.

Non-fiber based packaging, such as plastic, glass and metal packaging, is valued at US$460 billion – just over half of the total packaging market; plastic packaging alone accounts for around a third of the market.

However, many experts believe this industry is facing a transformation, with major players rethinking the use of packaging materials and their manufacturing processes.

A number of market trends for the textile packaging sector have been identified by the UK’s National Composites Network, including:

- hydrocarbon-free jute sacking to reduce the contamination occurring from oils applied during the processing of jute;

- moves toward bulk handling are leading to the replacement of small and medium-sized sacks by “big bags”, including antistatic bags to minimize the risk of explosion when transporting combustible materials, as well as bags with leak-proof seams or aluminum lining;

- growth of nonwoven products used as durable synthetic papers, such as for shipping envelopes, medical packaging, industrial bags, and military, electronic and inflatable packaging;

- nonwovens for food packaging, such as teabags, coffee filters and absorbent pads to reduce leakage and the spread of blood and other juices from meat packaging;

- narrow-woven polypropylene strappings are now growing in popularity as a replacement for metal straps, which can be dangerous when cut under tension;

- growth of net packaging owing to the overall movement of food as well as pre-packaging of food, such as fruit and vegetables, that has otherwise been sold loose;

- intelligent packaging, including functional packaging such as temperature, freshness and traceability markers, and security detectors.

Main products

The main technical textile products used for packaging are:

- polyolefin woven sacks with an estimated 50% by volume of all textile packaging;

- jute hessian and sacks (including food-grade jute bags) with an estimated 30% by volume of all textile packaging;

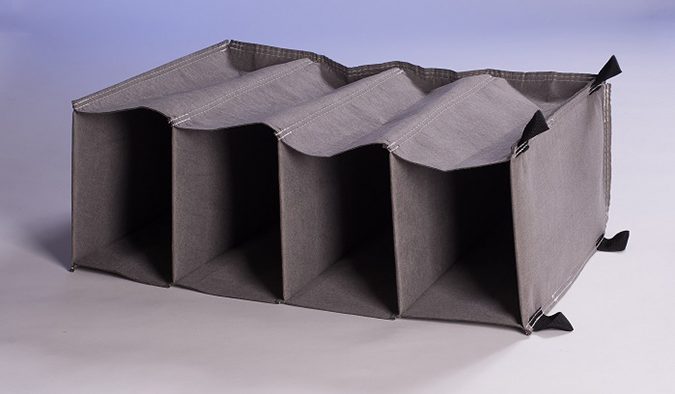

- flexible intermediate bulk containers (FIBCs);

- wrapping fabrics;

- leno bags;

- non-paper teabags and coffee filters;

- soft luggage products.

Woven sacks

Polyolefin woven sacks, generally made from high-density polyethylene or polypropylene (HDPE/HDPP), are versatile packing materials used extensively in the packaging of cement, fertilizers, chemicals, thermoplastic raw materials, grains, sugar, salt, cattle feed, etc.

Compared with other packaging materials, HDPE/HDPP offers the advantages of high strength, light weight, minimal seepage, moisture proof, durability and low cost as it can be reused.

Jute hessian and sacks

Jute fabrics and bags offer high mechanical strength, low cost, a soft surface with high frictional resistance to sustain high stacking of filled bags in storage and transit, and a porous structure that allows ventilation of, for instance, grain and vegetables.

Also known as burlap, jute hessian is a finer quality jute fabric that has been used for centuries as a packaging material for all kinds of goods. Hessian is used for bags and other uses, such as wrapping, wallcoverings, upholstery and home furniture.

Jute sacking generally refers to the coarser and heavier cloth, which is used primarily for sacks for packing materials. Jute sacking bags are particularly used in the cement industry and for storing agro-based products.

FIBCs

FIBCs, also known as jumbo bags, are similar to HDPE/PP bags, but are larger. They are a cost-effective packaging solution for shipping and storing dry bulk products and can be produced from either tubular or flat woven PP fibers; the fabrics can be coated or uncoated.

There are three main types of FIBC bags: panel type, circular woven and baffle type (square bags). The bags have capacities of 500-4,000 kg and a fabric weight of 180-275 g/m2. The FIBCs themselves can weigh 900 g to 3 kg, depending on the bag properties and weight to be carried.

FIBCs offer such benefits as low cost and ease of material handling, low weight for transport, no requirement for pallets compared with small bags, good chemical and organic resistance and recyclability; they can also be used for storage in open air if UV stabilized.

Leno bags

Leno bags are used for packing and preserving a wide range of vegetables and fruit. They are made of a woven net fabric from virgin PP with a color masterbatch.

Leno bags offer superior aesthetics, excellent mechanical properties, chemically inert, ease of handling and storage, reusability and recyclability. They can be a cost-effective solution and are suitable for dry-skin vegetables (e.g., potatoes, onion, garlic, etc.) and for cold storage.

Wrapping fabric

With a basis weight of 50-200 g/m2, wrapping fabric can be designed to be tear resistant, thin and lightweight with a high tensile strength. It is generally made from HDPE/HDPP or cotton canvas. Unlaminated HDPE/PP woven fabric is mainly used for wrapping paper rolls, paper bundles, steel coils, tires, yarn cones, etc.

A leading producer is Beaulieu Technical Textiles, which offers industrial packaging solutions in the form of rolls of coated or uncoated woven PP under the Durapack brand. These can be used, for example, for the packaging of technical textile rolls, such as wrapping around yarns or bulk fibers, wall-to-wall carpets and tufted carpets.

Teabags

Teabags are commonly made of filter paper or food-grade plastic, or occasionally of silk cotton or silk. Teabag filter paper can be a blend of wood and vegetable fibers, such as bleached pulp abaca hemp or lyocell. Heat-sealed teabag paper usually has a heat-sealable thermoplastic, such as polyvinyl chloride or a bicomponent fiber, on the inner side of the teabag surface.

Soft luggage

Light and flexible soft luggage comprises products made from woven fabrics such as polyamide and polyester. It includes upright suitcases, tote bags and duffle bags, which can be with or without wheels and handles, as well as handbags, backpacks, wallets, briefcases and other soft-sided luggage items.

European developments

Increasing environmental awareness among consumers and the introduction of packaging-focused regulations, such as the Single Use Plastics Directive adopted by the European Parliament in March 2019, have incentivized European companies to accelerate their development of alternative packaging materials.

In December 2019, the European Commission published a roadmap for its new Circular Economy Action Plan. This specifically mentions packaging, with actions that focus on microplastics, requirements on packaging, and bio-based and biodegradable plastics.

Meanwhile, an alliance to promote the role that fiber-based packaging can play in circular economies, thereby minimizing their environmental impact, has been established by the Brussels, Belgium-based Confederation of European Paper Industries.

Called 4evergreen, the alliance aims to increase awareness of the benefits of fiber-based packaging materials. It will also advocate for EU legislation supporting their design for recyclability, and will call for the development of optimized systems and infrastructure for their collection and recycling.

The 4evergreen alliance offers a forum to connect companies from across the supply chain for fiber-based packaging, from paper and board producers to packaging converters, brand owners and retailers, technology and material suppliers, waste sorters and collectors.

Reusable wood-based bags

Austrian cellulosic fiber producer Lenzing has developed a reusable wood-based bag in partnership with VPZ Verpackungszentrum. The bags have been used in the supermarkets of Swiss food retailer Coop and Austrian firm Rewe International.

Made from Lenzing modal fiber using Forest Stewardship Council (FSC) certified beechwood, the Packnatur reusable bags are soft, breathable, moisture-regulating, tear-resistant and waterproof. They feature a wooden drawstring stopper that is also made from FSC-certified beechwood. The cellulose bags are particularly suitable for packaging fruit and vegetables and can be used as a replacement for plastic bags.