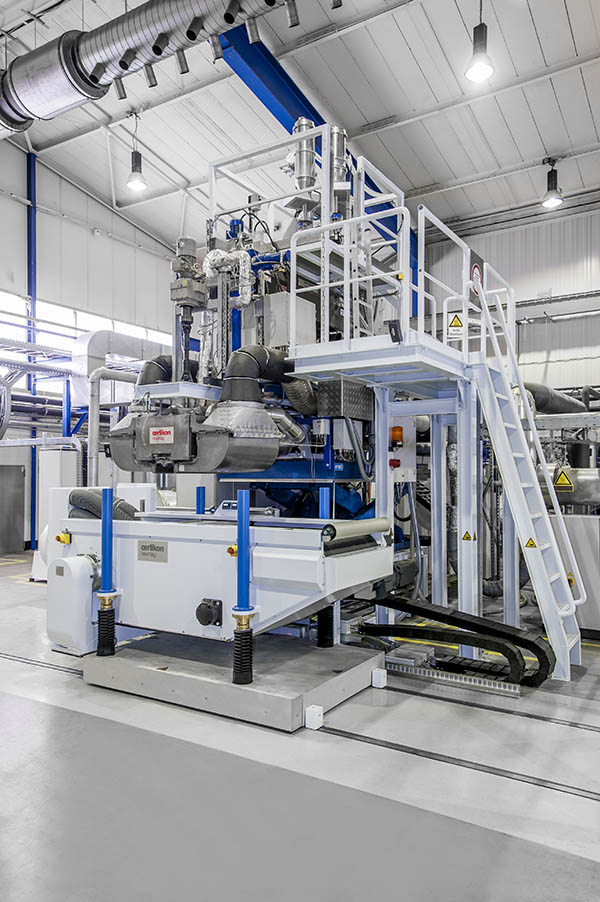

Oerlikon Neumag’s meltblown pilot plant

Almost 500,000 tons of nonwovens are currently used annually in the production of filters, which corresponds to approximately 10% of current worldwide industrial nonwovens manufactured. Here, the filter market is split into two areas: air and liquid filtration. While in excess of 170,000 tons of nonwovens were manufactured for gas/air filters in 2015, the volume for liquid filters was almost double at around 295,000 tons.

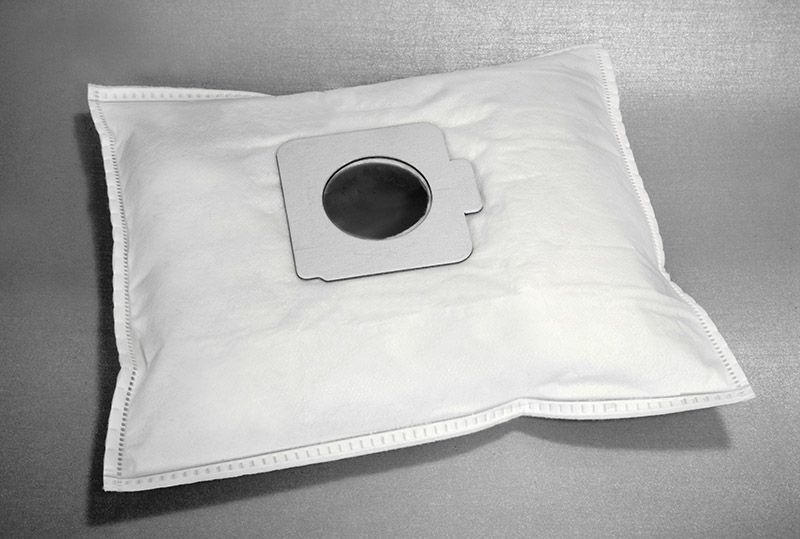

Depending on the specific application, the demands on filters are extremely high. To this end, high-efficiency particulate air filters for clean rooms must, for example, filter < 1µm particles from the air with virtually 100% efficiency. Filters must achieve their separation performance with the lowest possible pressure drop – in other words, filter resistance. Pressure drop is one of the most important quality features of filters: the lower the pressure drop, the more energy efficient the filter of the corresponding filter class is. A good example is vacuum cleaner filters. The class in the case of vacuum cleaners depends on the energy consumption, which is also influenced by the vacuum cleaner filter. If the filter is too dense, the vacuum cleaner draws more electricity and the energy consumption increases.

Comparison of two technologies

Highly efficient filters can either be manufactured from synthetic fibers or glass fibers. Today, filters in the HEPA and ULPA filter classes (the classes with high filter separation performances) in particular are still produced using glass fibers. Here, synthetic filters offer benefits: glass fiber filters achieve their separation performance only by means of the fineness of the pores. That is why the pressure drop is relatively high. In contrast, filters manufactured from synthetic fibers can be electrostatically charged. For this reason, their pores can be comparatively larger, which in turn considerably reduces the pressure drop. Furthermore, glass fiber filters harbor the risk that glass fiber particles can be released, which end up in the clean air, result in contamination and could be breathed in.

Efficient filters made from meltblown nonwoven materials

Meltblown technology is one of the most efficient methods for producing very fine and highly separating filter media made from synthetic fibers. Depending on the application, the pore size of a meltblown nonwoven material ranges from 5 to 40 µm. Here, smaller pores increase the mechanical filtration performance, albeit at the expense of higher pressure losses. The fineness of the meltblown fibers used for filter media lies in the 200 to 2,500 nm range. However, even fibers with nanoscale fineness are often not sufficient to filter the finest particles from air or liquid flows. For this reason, the nonwovens are treated online or offline; for example, they are electrostatically charged to increase their filter performance.

Electro-charging for superior filter separation performance

The filter efficiency can be considerably increased by means of so-called electro-charging – where the nonwovens are electrostatically charged. There are two options for charging nonwovens for industrial applications: triboelectric charging or corona charging. Today, corona charging is the method predominantly used.

Oerlikon Neumag, one of the leading manufacturers of meltblown systems, is currently developing its own concept for electrostatic charging of meltblown nonwoven materials. This distinguishes itself from concepts currently available on the market due to its high flexibility with regards to charging the most varied nonwovens. Users can freely choose from a large number of variation possibilities and set the optimum charging method depending on the filter application. This multifunctional charging unit operates on the basis of corona charging and is suitable for thick and thin nonwovens with low and high basis weights. Initial laboratory trials have shown that the Oerlikon Neumag charging unit can also be used to manufacture EPA- and HEPA-class filters. For example, an H14-class filter with an efficiency of 99.995% at a pressure drop of less than 100 Pa has been produced.

Meltblown process for numerous polymers

The polymers used for manufacture are just as diverse as the applications for the filters. The spectrum ranges from PET, PLA, PBT polyesters, PA and polyolefins (PP, PE) all the way through to special polymers such as PPS and TPU. All these and further raw materials can be spun using the Oerlikon Neumag meltblown process. This process is characterized by its constant melt pressure distribution and simultaneously consistent dwell time across the entire width of the spinning beam, which in turn ensures particularly homogeneous nonwoven properties and basis weights. Furthermore, the innovative guidance and distribution of the process air outside the coat-hanger distributor offered by the Oerlikon Neumag technology prevents so-called hotspots. As a result, even extremely sensitive raw materials can be reliably processed into high-quality nonwoven media.

In-house R&D Center for innovative development

As a high-tech company with a clear commitment to research and development, Oerlikon Neumag is dedicated to continual innovation. At the comprehensively equipped meltblown R&D Center, the processes and the machine technology – along with the manufacture of application-optimized nonwovens – are continually tested and further developed. The pilot line has a spinning width of 550 mm and comes with additional equipment. A comprehensive range of testing devices and tools is available for analyzing nonwovens. By contacting the Oerlikon Neumag sales department, customers can also utilize the laboratory for their own product development and optimization.

Summary

The trend in filtration applications is very clearly increasingly focusing on ever more efficient filter media with minimum pressure drop. The Oerlikon Neumag meltblown technology is particularly suitable for this. This is also underlined by the orders placed with the Neumünster-based systems manufacturer by leading meltblown nonwoven material manufacturers over the past few months.

The overwhelming share of the filter media still used today is produced from multi-layer nonwoven laminates. Here, manufacturers generally have to resort to nonwovens that are available on the market. By using the Oerlikon Neumag meltblown technology, these filter media can be directly manufactured in a single-step process, whereby the producer then has complete control over the raw materials deployed and lower manufacturing costs as well as being able to reliably and consistently fulfill the high quality requirements of its customers.

For more information contact:

Oerlikon Neumag

Email: sales.neumag@oerlikon.com

Website: www.oerlikon.com/manmade-fibers