Battery separators are vital to the function and performance of batteries. Fibers play a significant role as the base component of a nonwoven membrane that acts as an electronically isolating layer between cathodes and anodes in a battery. These fibers require insolating properties, high mechanical strength, as well as electrochemical insulating properties. The type of fiber and processing technologies utilized in fabrication of the separator can be designed and tailored to meet a number of specific applications. The separator acts as an electron insulator, while allowing ions to move between electrodes. As a result of performing this function, the separator prevents short circuiting from occurring.

Fibers are utilized in a broad range of battery types and can be fabricated through a number of nonwoven processing technologies. These types of fibrous structures hold enough liquid electrolyte to enable ion exchange, while also enabling the pores to close should the cell overheat. These materials can also be utilized in composite formats with membranes.

The following are essential properties that are dictated by the fibers and their associated structure(s).

- Permeability (uniform to current density distribution)

- Porosity (important for absorption of the electrolyte)

- Thickness (the space for the anode and cathode may be adversely affected if the separator is too thick)

- Moisture absorption (should be high)

- Electrolytic absorption and binding (Ion flow)

- Swelling (The separator must not swell)

- Shape and dimensional accuracy (short circuit)

- Chemical resistance (should be ensured)

- Dielectric strength (short circuit prevention)

- Thermal stability (has to be ensured)

- Tensile strength (separator must not contract)

- Pore size (should be as small and as uniform as possible)

- Curvature of the edges (the edges should be completely straight)

- Shutdown (as a safety feature)

Evolution of batter separators

The first battery separators utilized wood fibers. However, these fibers quickly deteriorated within the electrolyte. Separators were later manufactured from glass fiber mat, polyurethane and rubber. Currently, polyolefin separators, such as polyethylene (PE) and polypropylene (PP), are widely used in commercial battery separators due to their insulating properties, high mechanical strength, and excellent electrochemical stability. The past few years have witnessed significant progress in the development of biopolymer fibers for use as separators. Compared to synthetic materials, biopolymers are more sustainable/environmentally friendly, while still meeting all the core requirements of thermal stability and strength.

Carbon fiber is an emerging material that is expected to see significant increase in utilization in the electric vehicle infrastructure. These fibers will be employed in a variety of charging station components, and they can be incorporated into much of the charging station charging cords and wireless charging pads to increase strength, durability and safety.

Applications

All commercial batteries use separators, though different types of battery systems require different types of separators. The primary battery technology segments for battery separators include lithium ion and lead acid. Lithium-ion batteries are one of the most efficient available in the market and are widely utilized in automotive and consumer electronics. Lead acid batteries are the second most utilized battery technology; however, this is an older technology and not as efficient as lithium ion or other emerging technologies.

The primary application for battery separation today is linked to energy storage and transportation. Fibers can play an important role, not only in the production and use of the cell, but also in the end of life. According to the U.S. Department of Energy (DOE), “99% of lead-acid batteries in the U.S. are recycled, while only 5% of lithium Ion batteries are currently recycled.”

The lithium-ion battery industry lacks a clear path to large-scale recycling, as battery researchers and manufacturers have not traditionally focused on improving recyclability. Instead, they have worked to lower costs and increase battery longevity and charge capacity. Fiber advancements could play a significant role in simplifying the disassembly process, and thus aiding in sustainability initiatives related to battery separators.

The potential for carbon fiber

Carbon fiber is an emerging material that is expected to see significant increase in utilization in the electric vehicle infrastructure. These fibers will be employed in a variety of charging station components, and they can be incorporated into much of the charging station charging cords and wireless charging pads to increase strength, durability and safety. The scale of materials required for electric transportation infrastructure could enable the use of these materials in separator applications as well, due to the price and availability as commercialization of such technologies ramps up.

Parting thoughts

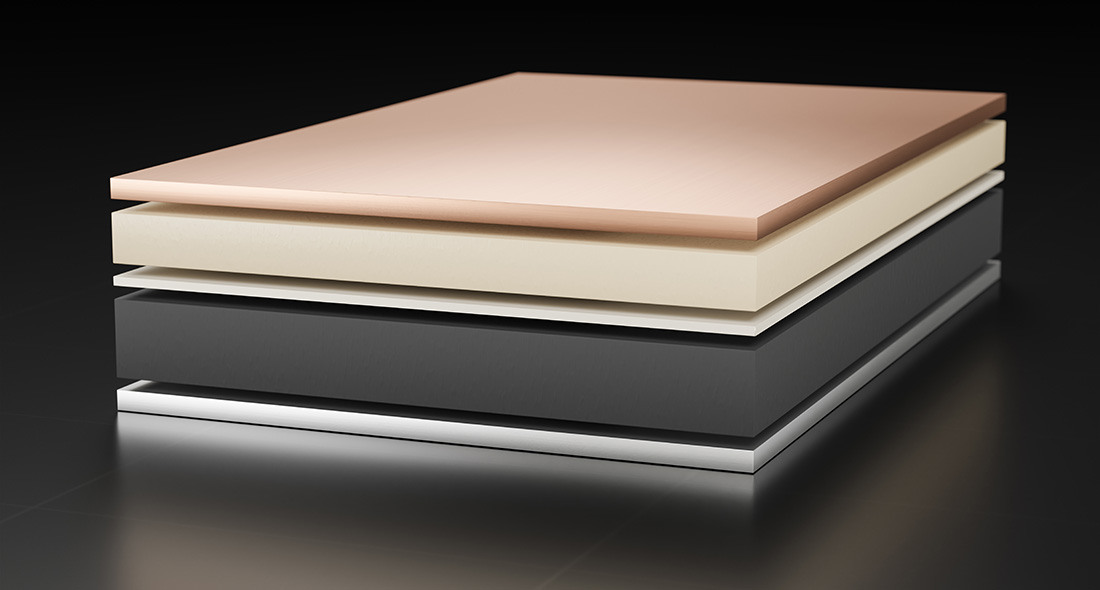

Battery production primarily uses carded nonwovens, wetlaid nonwovens, meltblown fabrics and spunbond fabrics as separators. These are usually still needled or hydroentangled to obtain certain properties, e.g., a larger surface by means of felting. Depending on the respective manufacturing process and field of application, nonwovens are subsequently further equipped in order to generate additional special effects – hydrophilization (increase in fluid intake capability) and ceramic equipment are just two options for increasing the efficiency of a battery.

The precise manufacturing processes required for battery separator technologies are aimed at achieving tightly controlled fiber formation, uniform pore structure, chemical stability, high wicking and absorbency, mechanical strength, and accurate control of thickness and weight. Nonwoven battery separators tend to be either wetlaid glass or meltblown polypropylene. Nanofibers can also be incorporated onto the nonwoven material.

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).