Interview with BP Sultania, Joint President, Ganesha Ecosphere Ltd, India

The demand for recycled polyester staple fiber (PSF) is growing in production of textiles and clothing with each passing day. This is happening due to increased consumer awareness on using apparels produced sustainably. Due to this awareness, various garment brands and retailers like H&M, Target, Zara owner Inditex, C&A, etc. have started using recycled PSF in their garments.

Recently, the European Union (EU) has also introduced a law that by 2030, textile products placed in the EU markets should be long lived and recyclable and to a great extent made of recycled fibers, free from hazardous substances and produced in respect of social rights and the environment.

The nonwovens industry is also expanding all over the world with exponential growth. It has increased by three to four times in the last 10 years, with still lots of scope for growth as nonwoven fabrics have now entered into all aspects of life like carrying bags, baby diapers, wipes, filters and many other products.

International Fiber Journal met with CEO BP Sultania, Joint President, Ganesha Ecosphere Ltd., based in Kanpur, India, on his company’s developments with the PET recycled polyester staple fiber marketplace. Ganesha Ecosphere recycled more than 40 billion bottles in last decade, and that figure is just multiplying day by day. The company focuses on yarn spinning, nonwovens, flame retardant fiber, fiber filling and spun yarn.

International Fiber Journal: Kindly provide a history about your company.

BP Sultania: India-based Ganesha Ecosphere Ltd. was established in 1988 by Shyam Sunder Sharma, a textile veteran with more than 50 years of experience. Ganesha Ecosphere was also the first Indian company to set up a PET recycled polyester staple fiber (PSF) plant in 1994 at Kanpur, in the state of Uttar Pradesh, with a small capacity of 4,200 tons per annum.

Initially, there was no awareness about recycled PSF in India among polyester yarn manufacturers. The biggest challenge before us was to educate and convince customers to buy recycled PSF. It took us nearly 10 years to fully utilize full capacity of our first plant, before embarking upon the first expansion project in 2006.

Once we started using the full capacity of our first plant, the recycled PSF production capacity was further increased by setting up another recycled PSF plant at Rudrapur in the state of Uttarakhand in 2006, and then another plant was set up again in the state of Uttar Pradesh in 2014.

IFJ: Share details about your manufacturing and annual capacity.

Sultania: Ganesha Ecosphere is mainly focusing on recycling PET bottle waste to convert the same into products like recycled PSF, spun yarns, filament yarns and bottle grade/textile grade chips, etc.

We have recycled PSF installed capacity of 111,600 tons per year, recycled bottle grade chips capacity of 14,400 tons per annum, recycled textile grade chips with an annual capacity of 14,400 tons and

recycled fully drawn yarn, whose yearly capacity is 2,700 tons. We also have a 25,600 spindles spinning mill, which produces recycled spun yarns.

IFJ: What made your company take up PET recycling?

Sultania: We have been recycling textile industrial waste into fibers, having installed small crimping and stretching machines since our inception. These were just locally made machines but it gave us an insight into the recycling business. There were very few PET recyclers in the world in the 1990s. The use of PET too kept on increasing and there were grave concerns on the disposal of post-consumer PET bottles. Keeping this in view, we decided to go in for a PET recycling project.

IFJ: What has been the gestation period for being able to produce the right quality of recycled PSF?

Sultania: Since this was totally a new technology, our biggest challenge was creating a domestic market for recycled PSF. With continuous efforts and market intelligence, we found some scope for use in a worsted spinning system as a substitute for wool fiber. Initially, although our quality was low but due to big price gap between wool and recycled fiber, it found acceptability, albeit on a small scale. But this gave us an incentive to put in more effort to produce the highest quality of recycled PSF, which took us around three to four years.

IFJ: What is the system for collection of post-consumer PET bottles waste?

Sultania: There is no formal municipality-controlled PET bottle waste collection system in India, but the entire system is handled by PET bottle bailors and aggregators, who buy waste collected by rag pickers, etc.

Ganesha has a well-organized PET waste collection system spread across India. We also have our own collection centers managed by the company or business associates. The PET bottle waste is supplied to us by around 500 bailor and aggregators, who have been associated with us since inception.

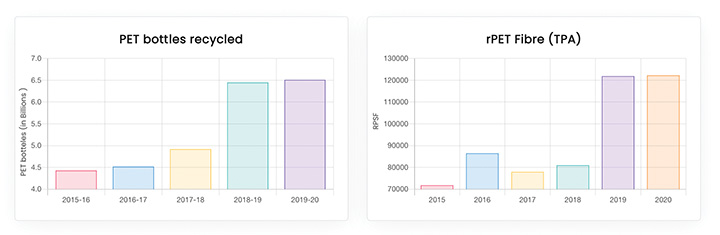

IFJ: How much post-consumer PET bottles are being recycled in India?

Sultania: India is successfully collecting and recycling around 90 percent of the total post-consumer PET bottle waste. The PET recycling industry had a turnover of around $500 million in 2015, which touched around $700 million in 2020 [1], growing at an annual rate of 8 to 9 percent.

IFJ: What are the core company products and solutions you offer for the market?

Sultania: The core product of the company is recycled PSF which is extensively used in yarn spinning, for producing nonwoven fabrics and is also used as filling for pillows and mattresses. Ganesha supplies a wide range of PSF in the range of 1 to 70 deniers in different cut lengths for various end users.

Ganesha has also introduced specialty recycled fibers like flame-retardant fiber, which offers protection from fire, anti-microbial fiber which offers 99.99 percent protection from bacteria and Coolfast fiber, which is a new generation specialty engineered fiber, with a unique combination of superior airflow and moisture wicking properties.

Ganesha also has in its portfolio biodegradable fiber, which is most suitable for single-use wipes and diapers, which ultimately head for landfills. But single-use wipes and diapers made with our biodegradable fiber, fully degrade in just one year, and help the waste return the organic components back to earth.

We also manufacture recycled short cut fiber for reinforcement in cement sheets, wall papers, batteries and air filters, etc. The addition of short cut fibers makes these products stronger.

IFJ: How much recycled content is being used by fashion brands?

Sultania: Clothing brands or retailers mainly use recycled PSF in garments which are blends of polyester fiber and cotton or viscose fiber. They use 40-50 percent recycled PSF in a single garment, while the rest 50 percent is either cotton or viscose fiber.

IFJ: How important is the sustainability factor for your company?

Sultania: Sustainability and circular economy are the hottest topics nowadays and we are very much pursuing it with passion. The recently introduced bottle-grade recycled chips is an example of circular economy. The virgin bottle grade chips, which are converted into PET bottles and discarded after use, are collected and then recycled into bottle-grade flakes and chips for use, again in the manufacture of PET bottles, thereby completing the cycle of circular economy.

Ganesha also has a Global Recycling Certificate issued by the Control Union, which confirms that our PSF fibers are 100 percent recycled. We also supply dope dyed fibers and yarns, wherein we obtained ZHDC certificate from our dyes suppliers, which confirms that the dyes are safe and free from harmful metals and are environmental friendly.

We also hold an OEKO-TEX Class 1 certificate and SEDEX 4 Pillar certificate, in compliance of social and environmental responsibilities. We also offer DNA-certified fiber which helps the end user consumer to identify that the garment has been manufactured from recycled fiber.

IFJ: What is the advantage of the products that you offer vis-à-vis those offered by the competition?

Sultania: Ganesha offers a full basket of products to customers for different segments and end use like conventional yarn spinning, nonwovens, fiber fill as well as various specialty fibers, all with environmental and sustainability certificates.

However, most of our competitors just focus on the conventional yarn spinning segment which gives us an added advantage to secure regular market orders from various segments, and operate our plants at full capacities, even if there is a slowdown in any one of the segments.

Until 2006, there were only three recycled PSF manufacturers in India, but it has now gone up to more than 40 manufacturers with an annual combined capacity of 1.2 million tons. Despite an overall massive increase in recycled PSF capacity in India, Ganesha has managed to retain its market share of around 15 percent.

IFJ: Please share details of your presence in the Indian domestic and export markets. Which industries do you cater to and what are the applications?

Sultania: We are exporting around 15 percent of our recycled PSF production to European countries like Germany, Spain, Italy, Portugal, Belgium, Poland and the UK. We also ship to the U.S., Nepal,

Bangladesh, Turkey and African countries. The rest is sold in the domestic market.

IFJ: Any planned capacity expansion or new investments in the near future?

Sultania: We are now expanding our recycled PSF capacity by 45,000 tons per annum in the southern part of India in the state of Telangana. Once the expansion goes online, our total recycled capacity will total 156,600 tons per annum. We are also increasing recycled bottled chips capacity by 28,800 tons per annum and will reach 43,200 tons per annum.

We are also increasing our yarn spinning capacity by adding 35,000 spindles which will go on stream by the third quarter of 2023. We are also setting up a line to manufacture recycled partially oriented yarn (POY) which will have a production capacity of 10,800 tons per annum.

IFJ: What are your expectations on the future growth and opportunities in the Indian as well as overseas markets?

Sultania: When considering just India, overall PSF production is 200,000 tons per month. Of this, virgin PSF output is around 100,000 tons and recycled PSF too is around 100,000 tons per month. This indicates that recycled PSF now has 50 percent Indian PSF market share.

We see consumption of recycled PSF to keep growing steadily, with growth in consumer awareness on using sustainable products. So, we are happy with the growth that recycled PSF has witnessed in the last few years, and this will continue in future too.

Moreover, increased consumer awareness to use garments produced sustainably has led to a higher use of recycled PSF in clothing. Due to this increased awareness, garment brands and retailers like H&M, Target, Zara owner Inditex, C&A, etc., also have started using recycled PSF in their garments.

Recently, the EU has also recently introduced a law that by 2030, textile products placed in the EU markets should be long lived and recyclable and to a great extent made of recycled fibers, free from hazardous substances and produced in respect of social rights and the environment.

We have inked a partnership with Moon Beverages Ltd., an authorized supplier of Coca-Cola India. The collaboration centers on utilization of recycled PET chips in food-grade packaging.

The nonwovens industry is also expanding all over the world with exponential growth. It has increased by three to four times in the last 10 years and there is still a lot of scope for growth as nonwoven fabrics have now entered into all aspects of life like carry bags, baby diapers, wipes, filters and many other products. With the increase in living standards, use of nonwoven products is going to increase with each passing day.

As per the directives of the Indian government, packaging units have to use minimum 30 percent recycled chips from the year 2025. This gives a very good growth opportunity to our bottle grade recycled chips segment where we have added new capacities.

In view of the above government directive, we have recently signed a contract with Coca Cola India to supply recycled PET resin. Furthermore, we have also inked a partnership with Moon Beverages Ltd., an authorized supplier of Coca Cola India. The collaboration centers on utilization of recycled PET chips in food-grade packaging. Due to all these factors, we foresee exponential growth for our recycled PSF, chips and flakes within the next few years.

IFJ: How do you see the future of Ganesha Ecosphere?

Sultania: Ganesha intends to increase PET recycling capacities by producing more value-added products. Keeping in view of more demand for recycled certified products, Ganesha intends to maintain its leadership not only in the Indian market, but also increase exports. Presently amongst top the 15 producers of recycled fiber in the world, our goal is to become the largest global recycled PSF maker in coming years.