A view of the North American nonwovens market and material consumption

Annually, INDA produces the North American Nonwovens Supply report based on extensive research, producer surveys and interviews with industry leaders. The report provides an overall view of North American supply, including the key metrics of capacity, production, and operating rates, in addition to regional trade, through the year 2020.

Based on that data, operating rates in 2020 were two-sides of the same coin, as some end-use markets were completely shut-down for a few months, notably building and vehicle construction, and other end-uses were operating full-out … if they could. Producers were challenged by workforce and transportation issues. As a result, the overall operating rate only increased one-percentage-point over 2019. Additionally, as the operating rate is based upon tonnage, the increased demand for lighter-weight materials – medical apparel and fine-fiber meltblown – affected the total tonnage output, as some lines were running full-throughput of surface area, but not tonnage.

Production by raw material usage

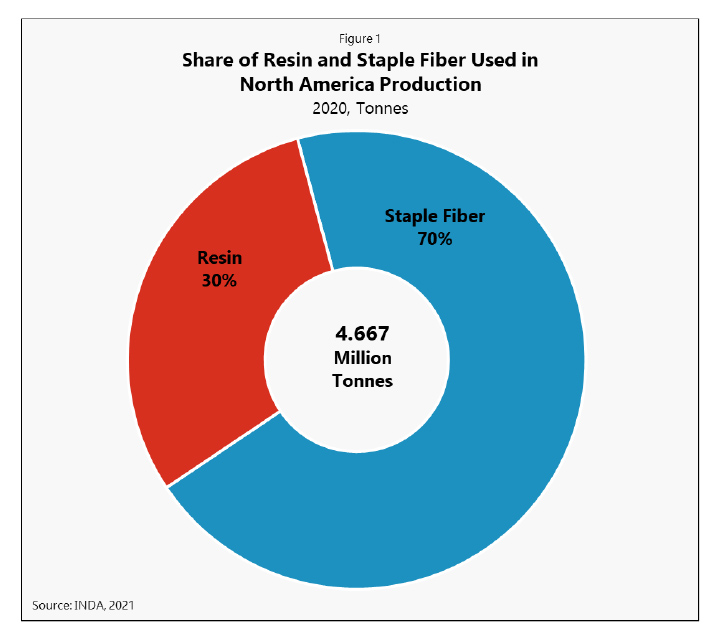

In 2020, the production of nonwovens in North America reached 4.760 million tonnes, 1.1% growth over the previous year. In 2020, the production growth outpaced that of capacity growth, resulting in the overall operating rate edging up to 86%. The figure below (Figure 1) displays the share of resin and staple fiber used in the North American nonwovens production, whether in the form of resins or fibers. Staple fiber represented 70% of the material usage in 2020. This is not surprising given that staple fiber represents 71% of the installed capacity base.

The share of the use of resin increased from 27% in 2019 to 30% in 2020, as the spunlaid production increased 8.4%. The production of the three web-forming processes using staple fiber declined 2.0% year-over-year.

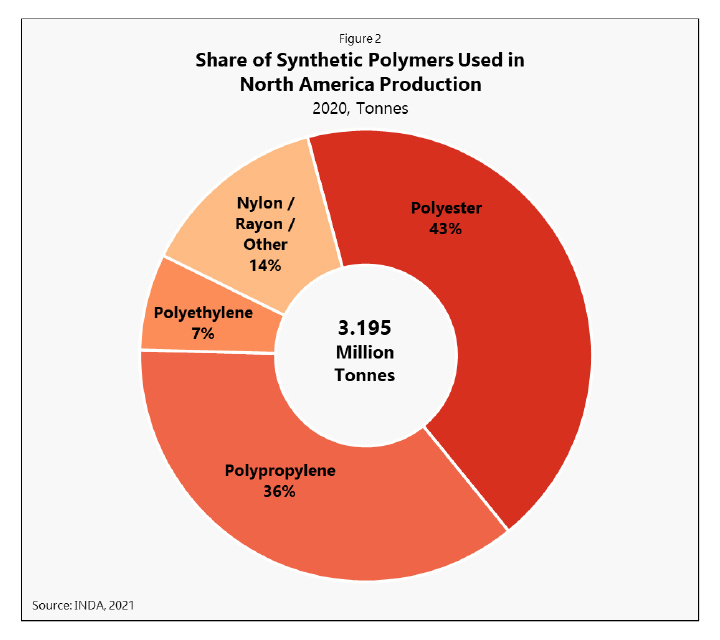

The raw materials used in the nonwoven production process can also be classified synthetic-based or natural. The next figure (Figure 2) displays the share of synthetic polymers used in the nonwovens industry, whether in the form of resins or fibers. Polyester is the most common synthetic polymer (43%), followed closely by polypropylene (36%). Polyester (PET) tends to be more used in the durable categories, and polypropylene (PP) in the disposable categories; as such, the share of PET declined by two percentage points from the previous year and PP increased by two percentage points.

Spunlaid resins

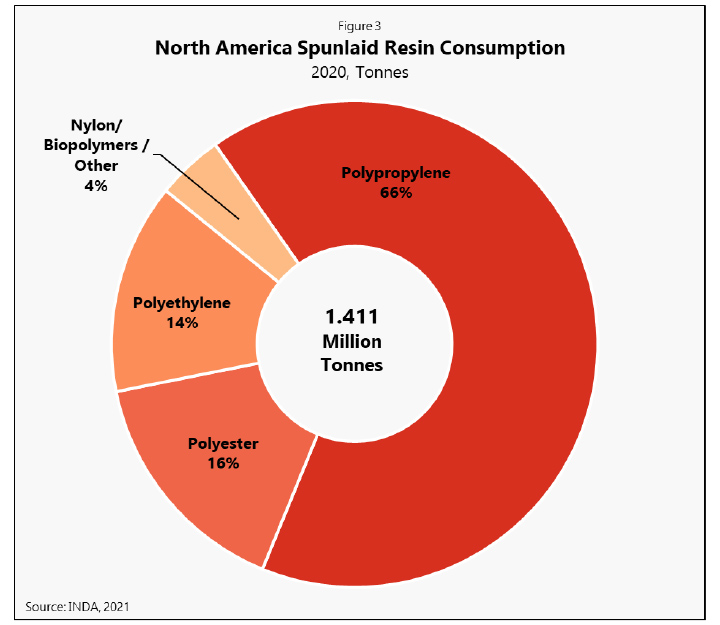

Resin consumption in the North American spunlaid processes was 1.411 million tonnes in 2020 (Figure 3). Polypropylene resin is the most widely used resin in spunlaid applications, accounting for two-thirds (66%) of the North American spunlaid market in 2020. Polypropylene has several advantages over other resins, and those advantages continue to drive its growth in new markets and maintain its dominant share position against other resins. Polypropylene has a specific gravity of less than one, lower than competing polymers; therefore, producers attain a higher yield per tonne using PP rather than competing resins. The PP melt-spinning process tends to have a wider process operating window than other polymers, resulting in easier processing. In addition, polypropylene has pleasant aesthetics of softness and pliability, and thus is used widely as coverstock in diapers, feminine napkins and disposable apparel. Polypropylene is also the predominate resin in the meltblown process.

The next most widely used resins are the polyester resins (PET ‒ polyethylene terephthalate and PBT ‒ polybutylene terephthalate) at 16% (Figure 3). Polyester is primarily used in spunbond materials, but a small volume of this resin is consumed in meltblown production. Durables are the principal end markets for spunbond polyester, with the exception of fine denier spunbond polyester for fabric softener sheets. Polyesters are also used in applications requiring higher temperature resistance, since polyester resins have a melt temperature in the 230 to 260-degree Celsius range.

Staple fiber

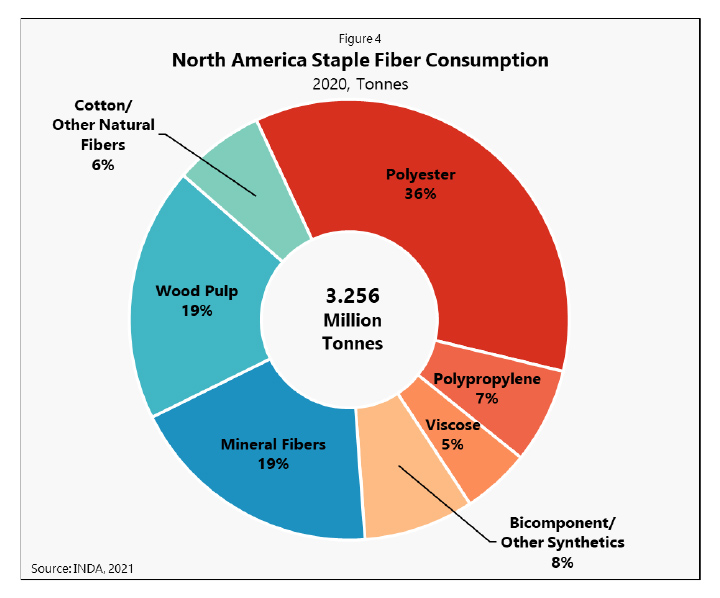

The North American consumption of staple fibers by the drylaid, wetlaid, and airlaid short-fiber nonwovens production was 3.256 million tonnes in 2020. The synthetic fibers (in shades of orange) accounted for slightly more than half (56%) of the staple fiber used (Figure 4). This was the same share as the previous year.

Polyester staple fiber accounted for 36% of fiber utilized by nonwoven producers in 2020 (Figure 4). In North America, the recycled share of polyester staple fiber consumption was 26% in 2020, up from 24% in 2019. While a large portion of the virgin polyester staple fiber can be attributed to the production of hydroentangled materials destined for the wipes industry, the transportation end use (e.g., carpeting, trunk liners, wheelhouse liners, underbody systems) consumes large volumes of fiber for heavier weight needlepunch products made of recycled polyester fibers.

Polypropylene staple fibers accounted for 7% of the staple fibers used in 2020 (Figure 4). While PP staple fiber usage has declined in the disposable market, in particular drylaid thermal bonded coverstock materials (only partly compensated by utilization of airlaid), this fiber continues to grow in supplying the durable nonwovens market. Most of the large durable end markets for PP staple fibers are needlepunch durables. The major markets that consume needlepunch PP include geosynthetics, vehicle components, and home/office furnishings (primarily indoor/outdoor carpeting, blankets, upholstered furnishings and bedding materials).

Viscose (rayon) staple fiber, including those of the lyocell process, accounted for 5%, mainly driven by the wipes and medical products industries.

Mineral fibers—including carbon, ceramic, glass, and metal fibers—extensively used in North America, primarily in the wetlaid process, accounted for 19% (in weight) of the staple fiber production in 2020. Glass fiber is made from extremely fine fibers of glass. It is a lightweight, extremely strong, and robust material. Glass fibers have applications in filtration, transportation, construction, electronics, wind energy, industrial, and others. Mineral fibers are also used in airlaid short-fiber and drylaid needlepunch processes.

Wood pulp, primarily that of southern bleached softwood kraft (SBSK) fluff pulp, consumed by airlaid short-fiber, drylaid hydroentangle, spunbond, spunlaid coform, and wetlaid processes accounted for 19% of the staple fiber production in 2020. Surprisingly, wood pulp is used in all the processes; approximately 50% of wood pulp is used in the wetlaid process (primarily for wipes and filter media), 27% in airlaid short fiber, 16% in spunlaid (primarily Kimberly-Clark’s coform and Berry Global’s Spinlace products) and 7% in drylaid hydroentangle.

Both cotton and natural fibers (such as jute, flax or hemp), together accounted for 6% of the staple fibers consumed in 2020 nonwovens production. Cotton is also used in many other domestic and personal care products, such as medical sponges, pharmaceutical coil, disposable wipes, tampons, cosmetic pads, beauty coils, jeweler padding and several other miscellaneous products. Although produced from a garnet or carding system, these uses are not generally counted as nonwovens production.

Staple fiber represented 70% of the material usage in 2020. This is not surprising given that staple fiber represents 71% of the installed capacity base. The share of the use of resin increased from 27% in 2019 to 30% in 2020, as the spunlaid production increased 8.4%. The production of the three web-forming processes using staple fiber declined 2.0% year-over-year.

Looking forward

While the North American economic and population forecasts are the basic building blocks of the North American nonwovens demand, like all aspects of life, the coronavirus pandemic has significantly impacted the nonwovens markets, in the short-term and, most likely, forever.

The nonwovens industry has responded to the pandemic and will continue to provide materials that keep the surfaces we touch clean, protect the air we breathe and provide a barrier to keep our bodies safe. Notably, the filtration, wipes, and medical/surgical nonwovens markets will experience increased demand through the next couple of years to meet the need for these protective materials.

The industry has also responded by investing in new assets to ensure the steady flow of these needed materials. Across the two-year period, 2020 and 2021, the nonwovens industry has publicly announced investments of $187 million. However, in the next two years, 2022 and 2023, the nonwovens industry has publicly announced investments of $318 million, funding incremental capacity additions and new lines.

It is a great time to be in nonwovens and will continue to be so through the next few years as demand and, correspondingly, supply to meet that demand continue to increase, and nonwovens continue to protect and improve our lives. We are in a business that is expanding faster than the economy as production growth exceeded U.S. real GDP for the seventh consecutive year. Production growth also exceeded capacity growth for the fourth consecutive year. The overall operating rate for the industry also improved for the fourth consecutive year.

North American Nonwovens Supply report

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).