Not too long ago, deep in a cave in the Eurasian country of Georgia, archaeologists unearthed the world’s oldest textile fibers – flax (linen) fibers dating back 30,000 years or more. Early humans recognized the importance of bast fibers and used the plant to revolutionize the way they made baskets, ropes, string and ultimately textiles. Fast forward to modern day and bast fibers have once again been identified as a novel fiber source – this time for the global nonwovens industry.

The nonwovens industry is undergoing a period of rapid change spurred on by growing awareness of the environmental damage caused by single-use plastics. Industry, brands and consumers are searching for a truly natural fiber that does not sacrifice performance in favor of sustainability. Historically, bast fibers have played a small role in the nonwovens industry, but recent advancements in fiber processing and innovation now allow these fibers to become more prominent in nonwoven fabric production.

Future of nonwovens

The market for natural fibers is set for rapid growth between now and 2030. This step change in demand is being driven by the combined forces of global plastics legislation, strong consumer preference for natural products and ambitious goals being put in place by major brands to decarbonize and eliminate plastic from their supply chains.

This reduction in plastic consumption is bound to increase the use of manmade cellulosic fibers (MMCFs). Viscose, at the time of writing, seems unlikely to be included as a plastic under the European Union Single-Use Plastics Directive, which is welcome news for much of the industry. However, several non-governmental organizations (NGOs) have recently expressed concerns about increased demand for MMCFs creating untenable pressure on global forest resources. These NGOs are calling for alternative natural sources of fiber and cellulose, particularly from annual agricultural crops such as hemp and flax.

Why choose bast?

Bast fibers – including hemp, flax, jute, kenaf and others – are an excellent alternative to MMCFs and an easy addition to standard crop rotation cycles. They are fast-growing annual crops that can be grown in almost all climatic zones and are powerful carbon sequesterers. These crops produce large volumes of biomass per hectare with minimal requirement for chemical inputs or irrigation. They are also proven to be beneficial for soil health, improving yields for following wheat and soybean crops. The use of these fiber crops does not displace food crops as the fiber is a by-product of both the food and construction industries.

The market for natural fibers is set for rapid growth between now and 2030. This step change in demand is being driven by the combined forces of global plastics legislation, strong consumer preference for natural products and ambitious goals being put in place by major brands to decarbonize and eliminate plastic from their supply chains.

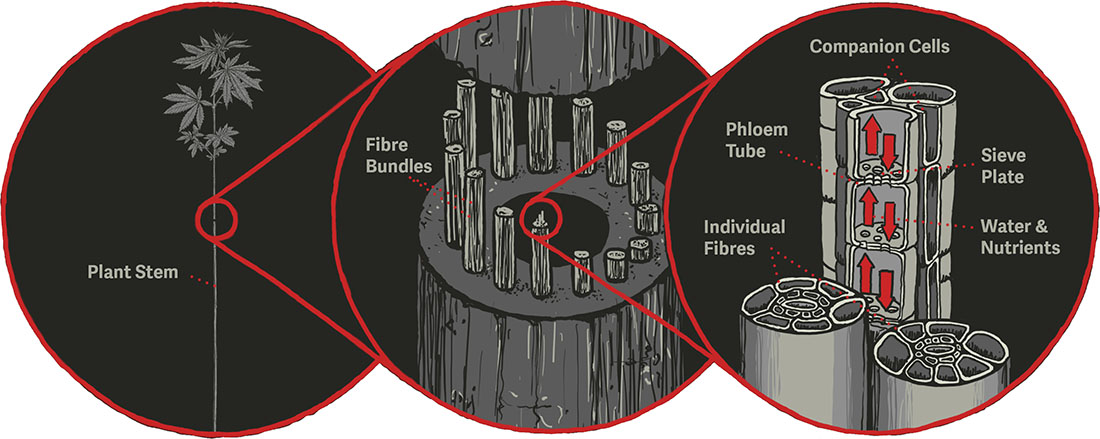

Plant transport tissues

Phloem fibers in bast plants are found just below the bark and are responsible for the translocation of soluble organic compounds, primarily liquid sugar, throughout the plant. In essence, these fibers are the nutrient highways of the plant and responsible for moving sap up and down the length of the stem. Turgor pressure within the phloem fibers resists the force of gravity and keeps the moisture where it is required.

When phloem fibers remain intact through the processing stage and not damaged via pulping or regeneration, the moisture management characteristics of the fiber can be transferred to the nonwoven substrate. This is especially important in wet wipe applications where the liquid in traditional synthetic and MMCF wet wipes is prone to leaching from the fabric and pooling in the bottom of the cannister. With bast fiber content wet wipes, this does not occur.

Supply chain management

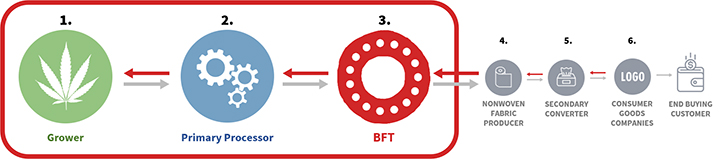

Bast Fibre Technologies (BFT) of Canada has taken a comprehensive approach to quality control and supply chain management to ensure nonwoven fiber standards are met.

Quality starts in the field

Bast fibers are an annual crop and fiber quality can be affected by geography, climate and agronomics. BFT ensures, through oversight of the raw material supply chain, that the harvested fiber meets the needs of the nonwoven industry. Mitigating raw material risk is critical to ensure fiber quality, stable pricing and continuity of supply.

Manufacturing technology

Once stripped from the plant, bast fibers are cemented together by glues and other substances that must be removed to individualize the fibers. Many companies around the world claim to be able to “degum” bast fibers, but the fiber quality from those suppliers rarely meets the exacting specifications necessary for nonwovens production.

Strict quality control measures must be in place to guarantee that processed fibers will be homogenous, regardless of raw material origin or processing location. BFT has identified and mapped more than 100 critical process control parameters that must be managed to produce a fiber that meets the industry’s specific requirements.

Raw bast fibers are very coarse, measuring well over 50 microns in diameter. Properly cleaned fibers are homogenous in color and length, free of microbial contamination and are approximately 15 microns in diameter.

Beyond sustainability

Too often consumers are asked to sacrifice performance in favor of environmental sustainability. By contrast, BFT of Canada, has developed a wide range of finishes and treatments that allows the fibers’ performance to be tailored to suit the needs of specific end-use markets. These proprietary fiber enhancements improve the fibers’ performance without sacrificing the environmental claims. Such treatments include cohesion enhancement, sanitizer compatibility, softness, color modification, antimicrobial and moisture management. BFT’s fibers are suitable for products ranging from industrial cleaning wipes to personal care and dispersible wipes.

Nonwoven fabric conversion

BFT has successfully demonstrated that its proprietary fibers can be processed on the major nonwoven conversion platforms without a decrease in efficiency or quality. There are, of course, variations in fiber blend ratios that are dependent on the nonwoven platform in use, but BFT has shown that its fibers can run from minority blends through 100% bast fiber concentrations. Fabric strengths of MD 40N+ and CD 20N+ are possible in all blend ratios and on carded spunlace nonwoven lines.

Wetlaid formation has been tested in laboratory settings with positive results. Good formation and strength are achievable along with excellent dispersal characteristics. Bast fibers are particularly interesting in wetlaid applications, as they enable the formation of a 100% plastic and regenerated cellulose-free sheet that meets the requirements set by the International Water Services Flushability Group without contributing to marine microplastic contamination.

Bast fibers – including hemp, flax, jute, kenaf and others – are an excellent alternative to MMCFs and an easy addition to standard crop rotation cycles. They are fast-growing annual crops that can be grown in almost all climatic zones and are powerful carbon sequesterers.

Certifications

Sustainability is at the foundation of the BFT platform, and it is important that fiber innovations do not come at the expense of the environment. In addition to the required REACH and “Prop 65” compliance, BFT’s fibers and/or processes have been certified by Oeko-Tex, Flustix (plastic free), BPI (compostable), freshwater biodegradable and USDA 100% BioPreferred. BFT’s fibers are tree free, food safe and vegan friendly.

Race to replace plastic

Leading Certified Guaranty Companies have signed a treaty to lobby United Nations member states to develop a global treaty on plastic pollution. Many of these companies have made a public pledge to reduce or eliminate single-use plastics in their supply chains over the coming decade. This fundamental shift has highlighted the need for a truly natural fiber that runs well on nonwoven conversion equipment, meets the performance expectations of the consumer, is cost competitive, and can be composted at the end of its useful life.

Bast Fibre Technologies recognizes the important discovery those early humans made 30,000 years ago and is now building upon their achievements to deliver a truly natural and high-performance fiber to the global nonwovens industry.