In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: April 29, 2024

Elevate Textiles Names Jeffrey P. Pritchett CEO, Director

The Board of Directors of Elevate Textiles, a global provider of advanced, high-quality products and mission critical textile solutions, announced that Jeffrey P. Pritchett will join the company as chief executive officer and member of the Board of Directors on April 23.

Pritchett joins Elevate with more than 25 years of multi-industry global leadership experience in both public and private companies. He most recently served as senior managing director and senior operating executive of Cerberus Operations and Advisory Company LLC, an affiliate of Cerberus Capital Management L.P. He also held numerous Cerberus portfolio company board and leadership roles.

Earlier in his career, he served as chief operating officer and on the Board of Directors at Champion One LLC, executive vice president, chief financial officer and head of Global Operations at InnerWorkings and held senior leadership positions at Vertis Communications, including senior vice president and chief financial officer. Before that, he held various leadership positions at General Motors and Delphi Automotive.

Cone Denim Introduces COLOURizd™ Sustainable Color Technology

Cone Denim® launched COLOURizd sustainable alternative technology for denim at the Kingpins Show Amsterdam, in April. This technology, developed by COLOURizd LLC, allows for a wide range of colors and textures while minimizing processing steps, resulting in a more sustainable and efficient approach to textile coloration.

“Cone Denim is excited to launch this unique innovative color technology,” said Cone Denim Director of Innovation Caitlyn Holt. “Not only is this a first for Cone, but it is new to the industry. This technology will allow us to have a quantifiable impact with unprecedented natural resource savings per yard produced.”

COLOURizd’s revolutionary QuantumCOLOURTM technology transforms textile coloration by directly infusing pigments and a binder into the yarn fibers. This advanced process enhances the yarn with vibrant colors, can create visual texture, and also eliminates the need for traditional dye baths and lengthy wet processing. By doing so, it significantly reduces environmental impact, paving the way for a new era in sustainable fashion. It is bleach-safe and provides excellent shade matching and color consistency.

Fuze Technology gets EPA Approval for Antimicrobial Product

Fuze Technology recently announced the Environmental Protection Agency’s (EPA) registration and approval for its products used in textiles and surfaces for antimicrobial effects, as well as lifetime durability of its application.

“This is huge news for Fuze and for the textiles industry,” said Andrew Peterson, Fuze CTO. “The EPA has reviewed our product and verified that it is an antimicrobial that is retained by the fabric for more than 100 washes. That is a first in the industry.”

The EPA’s approvals uniquely position Fuze in the market, making Fuze the only antimicrobial that can last the life of the textile it is applied to. Fuze uses its patented process to create its products that are applied to fabrics using various application methods.

In addition to its antimicrobial features, Fuze’s technology leads with its chemical-free, anti-odor capabilities which also promote moisture wicking and significantly faster drying times, while not disrupting the fabrics look or feel.

Albany International to Shutter Facility in South Korea

Albany International Korea, Inc., an affiliate of Albany International Corp., announced its plan to discontinue manufacturing at its operations in Chungju, South Korea, and to transfer production to other Albany International manufacturing facilities.

This action will enable the Company to align forming fabric capacity with the local market demand and the needs of customers. This initiative to streamline operations is driven by existing and anticipated market conditions, and in no way reflects on the performance of the 76 affected manufacturing employees, who will be offered separation and outplacement assistance. The company remains committed to the local papermaking industry and will continue to provide customers with strong expertise in Product Application, Sales and Marketing, Service through the current Sales, Service & Application teams located in South Korea.

The transfer of production will be supervised by technical and manufacturing personnel to ensure continuity of customer supply and will be completed by July 2024.

INDA Honors Three Nonwoven Industry Professionals with Lifetime Awards

INDA, the Association of the Nonwoven Fabrics Industry, announced three worthy recipients for the INDA Lifetime Service Award and Lifetime Technical Achievement Awards.

David Powling, Paul Latten and Arnold Wilkie are being recognized for their key contributions to the advancement of the nonwovens industry and INDA.

“It is our pleasure to recognize David, Paul, and Arnold with these well-deserved awards. INDA appreciates their contributions in advancing the nonwovens industry and being advocates for INDA,” said Tony Fragnito, INDA president and CEO. “These Awards honor individuals with long-established records of service and technical achievement. All three have given their best both personally and professionally to the nonwovens industry and INDA.”

Powling and Latten will receive their awards at the World of Wipes® (WOW) International Conference, June 18 beginning at 4:30 p.m. Wilkie will receive his award at the RISE® Conference, October 1 at 4:30 p.m.

Kimberly-Clark Invests in Peru

Kimberly-Clark announced plans to invest in a new diaper production line at its Santa Clara Ate plant in Peru. The investment which will be complete later this year will meet demand for diapers in Peru and other Latin American countries.

Kimberly-Clark, the maker of Huggies diapers, is looking to strengthen its business in the country, where it also makes toilet paper at plants in Ate and Puente Piedra, and is active in other baby care categories including wipes and shampoo. Currently, Huggies’ marketshare in the country exceeds 50%.

Local news reported that the company is looking to achieve better cost efficiency to satisfy local buyers that are facing a harsher economic environment. The company will increase its offerings of smaller-size and accessible products, in addition to offering more products in smaller packages.

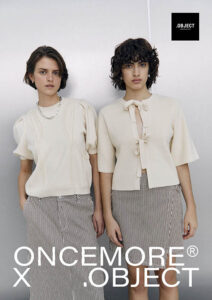

.OBJECT expands its fabric portfolio with OnceMore®

.OBJECT will expand its fabric portfolio with OnceMore® in its latest Spring collection set for release in April. OnceMore® enables a fabric made out of recycled textiles and wood from responsibly managed forests.

Danish fashion brand .OBJECT, owned by global fashion company BESTSELLER, and OnceMore® from Södra, the Swedish forest cooperative, join forces in .OBJECT’s latest collection. Rooted in a philosophy that celebrates creativity and beautiful quality, OBJECT’s collaboration with OnceMore® heralds a new chapter in their journey, weaving the innovative OnceMore® recycled fibre into their fabric portfolio.

OnceMore® stands at the forefront of textile innovation as the premier global solution for the large-scale recycling of blended fabrics. This pioneering process transforms textile waste and merges it with wood sourced from sustainably managed forests to produce a high-quality textile pulp, that then become viscose.

Indorama Looking to Close Dutch Polyester Plant

Europe’s polyester production crisis is deepening, and Indorama Ventures is taking steps to shutter a large polyethylene terephthalate (PET) plant in the Netherlands. The European Commission is attempting to stem further production cuts by imposing long-term antidumping duties on imports from China.

Indorama is entering a consultation process with employee representatives at its site in Rotterdam “to evaluate the possible future for production activities”—language that is often a harbinger of a plant closure. The site has an annual capacity for 426,000 metric tons (t) of PET and 700,000 t of the raw material purified terephthalic acid (PTA).

FullCare Medical Starts Medical Garment Production in Kenya

FullCare Medical has launched a new medical garment production facility in Tatu City, the 5,000-acre mixed-use Special Economic Zone (SEZ) in Kenya.

The FullCare Medical facility represents an investment of USD 30 million and employs 1,800 Kenyans in the first phase. In subsequent phases, the company plans to employ up to 7,000 Kenyans.

“Our selection of Kenya and Tatu City SEZ for our investment reflects our belief in the transformative power of collaboration. This state-of-the-art facility, leveraging cutting-edge solar technology for sustainable manufacturing, is poised to export USD 60 million of medical goods annually while catering to the local market’s needs,” said Lu Jianguo, Founder of FullCare Medical.

“Tatu City SEZ is attracting record foreign direct investment to Kenya. As Kenya’s first mixed-used SEZ, Tatu City has already attracted USD 2.5 billion in investment from more than 78 businesses — many of them global leaders in their fields, from healthcare and food and beverage production to call centers and software engineering. These investments are creating many thousands of much-needed jobs for Kenyans,” said Stephen Jennings, Founder and CEO of Rendeavour, the owner and developer of Tatu City.

The International Finance Corporation, the investment arm of the World Bank, provided USD 100 million in financing to FullCare Medical for its Africa expansion.

The FullCare Medical facility represents one of the most significant foreign direct investments in Kenya in recent years, setting the benchmark for dynamic and entrepreneurial Chinese companies in Africa.

Kimberly-Clark to Sell PPE Business to Ansell for $640 Million

Kimberly-Clark will sell its personal protective equipment business to Ansell for US$640 million in cash, agreeing to a deal that the Australian company’s chief executive said had been under consideration for years.

Ansell said it would acquire from Kimberly-Clark a business that designs, markets and sells gloves, eyewear and other apparel under the Kimtech and KleenGuard brands. Kimtech products are targeted at the scientific market, while KleenGuard is sold to industrial users. The deal comes as U.S. hospitals and healthcare buyers pivot back toward foreign-based buyers of personal protective equipment, after sales got a big boost during the early phase of the Covid-19 pandemic. Domestic mask producers, which had bulked up production over recent years in response to gummed supply chains and Covid-related demand, have been left with plants sitting idle, unfinished or operating below capacity.

The industry has also grappled with slack demand in recent years as laboratories, hospitals and clinics built up large stocks of gloves and other PPE equipment during the pandemic that they took time to run down.

Last month, Kimberly-Clark outlined plans to reorganize its business and overhaul its supply chain in a bid to rein in costs and streamline operations.

The maker of Kleenex tissues and Huggies diapers said it expected to book about US$1.5 billion in restructuring and reorganization charges over the next three years. It plans to reorganize into three businesses: North America, International Personal Care and International Family Care and Professional.

For Ansell, the deal represents an opportunity to double down on PPE and create savings through building a larger business, including in supply chains and organization. The Australian company already sells products to healthcare and industrial companies under brands that include TouchNTuff and HyFlex.

Ansell stated the transaction implied a valuation of the Kimberly-Clark PPE assets of 9.7 times earnings before interest and tax, ahead of any savings and tax benefits. It expects to close the deal between July and December.

Ansell added it would raise up to 465 million Australian dollars (US$306.0 million) to fund the acquisition and take on US$377 million in additional debt. The equity raising comprises a A$400 million fully underwritten placement of new shares to institutional investors, and up to A$65 million from a share-purchase plan.

NILIT Goes Circular with SENSIL®

NILIT, the global market leader, and a producer of high-quality Nylon 6.6 for apparel and owner of the SENSIL® brand recently introduced SENSIL® Flow, a new approach to Nylon 6.6 circularity that enables yarn, fabric, and, ultimately, apparel recycling to eliminate waste and further reduce apparel’s environmental impact. SENSIL® Flow is more than just a sustainable performance product. It is an innovative approach that engages the entire supply chain to truly attain circularity through product design and partnership.

“Our mission to create a more sustainable textile industry requires a shift in mindset throughout the value chain,” said Ilan Melamed, NILIT General Manager. “SENSIL® Flow represents an out-of-the-box approach that directly enables yarn and fabric recycling and lays the groundwork for apparel recycling and is part of a broader circularity mission for NILIT. Such a significant industry transformation can only be attained through deep partnerships that create innovative products and processes, visionary designs, and a collaborative reconfiguration of the value chain itself.”

“According to industry experts, more than 90 million tons of apparel end up in landfills each year,” said Michelle Lea, NILIT’s Chief Marketing and Sustainability Officer. “Only about a fifth of discarded clothing is reused or recycled. The SENSIL® Flow approach eliminates waste throughout the production chain and enables brands to design apparel that lasts longer and, at the end of an extensive life, can be more easily recycled.”

EDANA to Hold New Innovation Forum in June

EDANA will organize its first innovation forum in June 2024, focusing on innovation across all nonwovens applications. The inception of this new event emerged from the merger of two long-standing EDANA events: the International Nonwovens Symposium (INS) and the Nonwovens Innovation Academy (NIA). Historically, the nonwovens sector has been synonymous with innovation, furnishing society with adaptable materials that benefit daily routines, spanning healthcare, construction, filtration, household, and civil engineering among other sectors.

EDANA believes that convening the nonwovens industry at events is critical for the industry and can facilitate collaborative efforts for progress, while still safeguarding proprietary business data and respecting intellectual property. Open innovation not only breaks barriers but also streamlines costs, saving valuable time and resources by infusing diverse ideas into the innovation process and accelerating groundbreaking solutions. This is why in 2023, EDANA reviewed and strengthened the event offering to introduce the EDANA Innovation and Sustainability Forums.

Japan: Oji Holdings to Stop Producing Baby Diapers

Japanese diaper maker announced that it will stop producing diapers for babies in the country and, instead, focus on the market for adults. Oji Holdings is the latest firm to make such a shift in a rapidly ageing Japan, where birth rates are at a record low.

Sales of adult diapers outpaced those for infants in the country for more than a decade. The number of babies born in Japan in 2023 – 758,631 – was down by 5.1% from the previous year. It was also the lowest number of births on record in Japan since the 19th Century. In the 1970s, that figure stood at more than two million.

In a statement, Oji Holdings said its subsidiary, Oji Nepia, currently manufactures 400 million infant diapers annually. Production has been falling since 2001, when the company hit its peak – 700 million nappies.

Ontex Completes Divestment of its Algerian Business

Ontex, a leading international developer and producer of hygienic products and solutions, announced that it has completed the divestment of its Algerian business to Hygianis SPA, its local distributor for more than 20 years. The transaction includes Ontex’s production facility and business in Algeria, as well as related exports to certain neighboring countries.

Gustavo Calvo Paz, CEO of Ontex, said: “With this transaction, we make further progress in becoming the number one trusted partner for retail and healthcare brands, allowing us to focus even more on the strategic roadmap for our Core Markets of Europe and North America, where we have significant growth and margin improvement potential. I wish the full team of Algeria the very best while writing this new chapter of their story!”

The cash proceeds prior to taxes and transaction costs are approximately €25 million and remain subject to customary post-closing adjustments.

Bob Poovey, Champion Thread Founder, Dies at 82

Robert “Bob” Lee Poovey III, the founder of Gastonia, N.C.-based Champion Thread Company (CTC) in 1979 and continued to work at the company into his 80s, died March 28, 2024, at the age of 82.

Poovey managed a project to install a state-of-the-art, eco-friendly dyehouse at the company last year, which his son Matt Poovey, the company’s president, said is “nice little cherry on top of a long, 60-year career.”

GTT Expands PFAS-Free Finishing to South Korea

US-based textile treatment specialist Green Theme Technologies (GTT) is broadening its water and PFAS-free finishing platform into the South Korean market through a partnership with functional textile manufacturer, Hwasung International.

Hwasung International will become the inaugural Korean mill to offer GTT’s advanced Empel brand of dry-finishing formulations. These formulations have undergone rigorous testing and certification to ensure they are entirely free of PFOA and PFOS chemicals, commonly known as PFASs, by Bureau Veritas.

The collaboration between Green Theme Technologies and Hwasung International is a milestone in promoting environmentally friendly textile treatments in South Korea. By introducing PFAS-free finishing solutions, both companies are contributing to the industry’s shift towards sustainable and safer manufacturing practices.

Autoneum Expands Presence in Asia

Autoneum is expanding its production capacities in Asia with two new plants in Changchun in the Chinese province of Jilin and Pune in Western India. The expansion is in line with the Company’s strategic focus on future profitable growth with a special emphasis on Asian growth markets.

The world’s largest automotive market Asia is one of the most important sales regions for vehicle manufacturers and suppliers as well as a pioneer for new forms of e-mobility. Autoneum already supplies both international and local vehicle manufacturers in Asia with multifunctional lightweight components for noise and heat protection, supporting them in their commitment to sustainable mobility. Autoneum is expanding its production capacities in the key automotive hubs of China and India to increase its presence and thus its proximity to customers in these important production centers.

Autoneum’s new plant in China, which will be operated as a joint venture, will be located in Changchun in the northern Chinese Jilin province, which is one of Asia’s largest car production centers. The proximity to key local and international vehicle manufacturers makes Changchun a strategically important and attractive location for Autoneum. The plant will help to increase market share with European, Japanese and Chinese car manufacturers with products for light vehicles and also support the expansion of the Company’s business with components for commercial vehicles in this region.