In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: December 20, 2022

Dornbirn GFC call for papers

The Dornbirn Global Fiber Congress has issued a call for papers for the 2023 event, which takes place September 13-15 in Dornbirn, Austria. The program committee has defined the main themes of the 62nd event to be:

- Fiber Innovations

- Sustainability

- Circular Economy & Recycling

- Nonwovens & Technical Textiles

- Biomaterials & Biopolymer

- Smart Functional Surface

- Apparel & Sports

- Hometextiles

Interested parties can contact Austrian Fibers Institute with papers before the end of January 2023. Email: office@dornbirn-gfc.com

Hohenstein opens new testing lab in Shanghai

With the opening of another laboratory in Shanghai, China, testing service provider Hohenstein is growing its international network. Starting in the first quarter of 2023, the new textile laboratory in the Pudong District industrial park will supplement its Hong Kong laboratory capacity with testing and on-site inspection services in the hot spots of textile production.

The new laboratory will offer suppliers, manufacturers, brands and retailers a wide range of textile testing services. “Hohenstein stands for innovation and quality. We are very pleased to celebrate another milestone in our international expansion, while following these principles,” said Prof. Dr. Stefan Mecheels, who is the third generation to lead the family-run company. “No matter where the examinations, tests and analyses are carried out, all our laboratories work with state-of-the-art equipment and the same high standards.”

The laboratory locations in Germany, Hong Kong, Bangladesh, India, Hungary, and now Shanghai, offer shortened turnaround and sample transport times. In some locations, Hohenstein offers sample pick up services from the customer to the lab for testing. Mecheels emphasized, “Hohenstein is also aiming for customer proximity. Our goal is responsiveness and flexibility for our customers.”

Dow Jones Sustainability Index includes Gildan again

Gildan Activewear Inc. announced that it has been included in the Dow Jones Sustainability™ North America Index for its leading ESG practices.

This marks Gildan’s 10th consecutive year of inclusion in the DJSI. In 2022, Gildan was the only apparel manufacturing company included in the North American Index.

Gildan is also pleased to announce that for the third time it has been included in CDP’s Leadership Band in their 2022 Climate Change report. Gildan received an A- score for its environmental performance and the transparency of its environmental disclosures.

Lectra to acquire majority stake in TextileGenesis

Lectra announced the signing of an agreement to acquire 51% of the capital and voting rights of the Dutch company TextileGenesis.

As a major player in the fashion, automotive and furniture markets, Lectra contributes with boldness and passion to the Industry 4.0 revolution by providing software, equipment, data and services to brands, manufacturers and retailers.

Founded in 2018, TextileGenesis provides a Software as a Service (SaaS) platform that enables fashion brands and sustainable textile manufacturers to ensure a reliable, secure and fully digital mapping of their textiles, from the fiber to the consumer, and thereby guarantee their authenticity and origins. This solution ensures the traceability of TextileGenesis’ customers’ entire sustainable textile supply chain in order to meet the demands for transparency, driven by changes in legislation in a growing number of countries and by growing consumer awareness, thereby encouraging sustainable development.

Its innovative traceability mechanism, which addresses both ends of the textile value chain, as well as its network of partners for material certification, and its technology platform guarantee the exchange and tracking of reliable and secure data throughout a material’s lifecycle.

Several of the world’s most prestigious fashion brands as well as leading sustainable fiber producers are already convinced of the value of TextileGenesis’ innovative offer, which enables the connection of multiple actors of the sustainable fashion ecosystem on this platform.

Texas Tech’s Ramkumar to receive the Textile Association of India’s highest honor

Dr. Seshadri Ramkumar, FTA (Honorary), Professor, Nonwovens & Advanced Materials Laboratory at Texas Tech University (TTU), Lubbock, Texas, will be awarded the Textile Association of India’s (TIA’s) highest honor, “Honorary Membership” for 2023.

The TIA, perhaps the world’s largest professional association in the field of fiber to fashion supply chain with over 25,000 members, will bestow the honor to Dr. Ramkumar during its World Congress in Ahmedabad, India, Feb. 25-26, 2023.

Honorary Membership is the highest award bestowed by the association for people who have significantly contributed to the field as well as have advanced the sector by creating a new industrial landscape. The association has awarded this honor to stalwarts in the industry such as Dr. Vikram Sarabhai, who is recognized as the founder of India’s modern space, textile and management education sectors. Other dignitaries to receive the award include Mr. Kasturbhai Lalbhai of Arvind Industries; Mr. Dhirubhai Ambani of Reliance, who revolutionized the manmade fiber sector in India; and Dr. Vikram Sarabhai, the father of the Indian space sector, who studied under Nobel Laureate C V Raman, whose name is synonymous with Raman Effect.

Dr. Ramkumar collaborations over two decades in India has created a strong footing for the textile sector, the association noted.

Dr. Ramkumar is a tenured full professor of advanced materials and Texas Tech University. His research has resulted in commercial products such as FiberTect decontamination wipe and cotton-based oil absorbent wipes. He is credited with creating Technical Textiles revolution in India, which played a vital in India becoming self-reliant in developing PPE products during this COVID-19.

Avgol to invest in new line in North Carolina

Avgol® announced a significant investment in a new high-speed, high-capacity flexible multiple beam production line at its facility in Mocksville, N.C.

“The addition of this new line enables us to have even greater production capacity, delivering component materials that are ‘Made in America’ and offering more sustainable options for the growing North America market and around the world,” said Avgol CEO Tommi Bjornman. “This additional new line also enables the Mocksville facility to deliver additional meltblown nonwovens, ensuring we have extra capacity to meet market demand.”

Avgol, an Indorama Ventures Limited company, leads the global hygiene market with the most comprehensive range of ultra-lightweight spun-melt nonwoven fabrics. This new, sixth line at the company’s facility in Mocksville will see Avgol investing in new Reicofil 5 (RF5) technology and underlines the company’s commitment to the region as a domestic supplier. The investment will deliver biocomponent and corresponding high-loft capabilities, with the line producing materials for applications that meet the needs of upper tier products for Hygiene customers.

As part of the investment, Avgol is also introducing extra capacity for meltblown production, ensuring a continuous supply of this critical material for both the region and customers worldwide.

Oerlikon to acquire Riri to raise position in luxury market

Oerlikon announced that it has signed a definitive agreement to acquire Riri, a leading provider of coated metal accessories for the luxury fashion industry.

This transaction marks a milestone in Oerlikon’s growth strategy and diversifies Surface Solutions’ offerings and market access. The transaction is expected to close in the first quarter 2023, subject to regulatory approvals and standard closing conditions.

Riri, headquartered in Mendrisio, Switzerland, is a market leader in metal accessories manufacturing, with a wide product range and unique offering. The company supplies global leading brands in the luxury fashion industry and has a strong foothold in the Italian luxury market. The company has more than 1100 employees and expects to generate sales of EUR ~170 million (CHF ~165 million) in 2022.

Milliken & Company expanding operations in Sout Carolina

Milliken & Company, a diversified global textile manufacturer with more than 70 locations worldwide, announced plans to expand operations in Cherokee County, South Carolina. The company’s $27.4 million investment will create 75 new jobs.

Milliken is a materials science expert with a diverse portfolio serving the textile, flooring, specialty chemical and healthcare industries. South Carolina is home to more than 25 Milliken locations, including textile and chemical manufacturing facilities, showrooms and the company’s corporate headquarters in Spartanburg.

“Expanding Magnolia Plant made perfect sense to us as a company,” said Milliken & Company President and CEO Halsey Cook. “This plant is on the cutting edge of manufacturing excellence and innovation, and Cherokee County’s support is vital to its operation. We’re grateful for the partnerships with this community and the state, and we’re proud to call South Carolina home.”

Located at 157 New Milliken Road in Blacksburg, Milliken’s Cherokee County expansion will include newly added production lines to increase manufacturing capacity. Known as the Magnolia Finishing Plant, the facility specializes in workwear, military and flame-resistant apparel.

The expansion is expected to be complete by year-end.

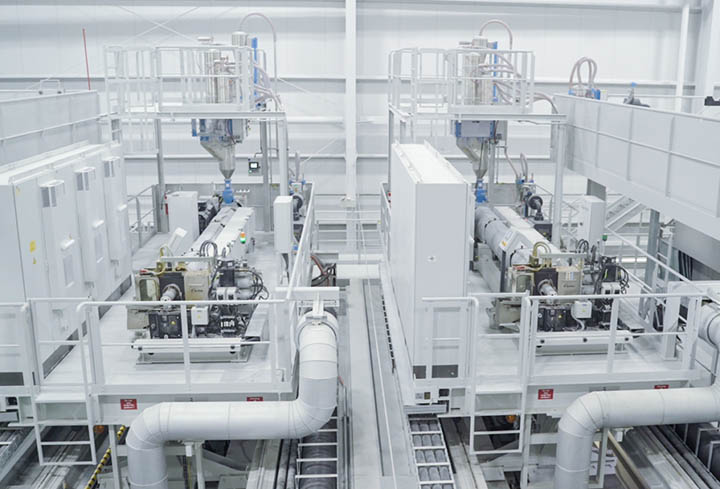

UGA Invests in Off-Site Lab

The University of Georgia (UGA) has invested in a new off-site laboratory to support the nonwovens and protective fabrics industry. Headed by Dr. Gajanan Bhat, the new facility will produce and test various nonwoven materials to help a wide range of manufacturing and related industries. Site engineer Joe Nageotte and technical consultant Mark Snider, a 30-year veteran of the nonwovens industry, also provide oversight of the lab.

A recently installed Southern Coastal Machinery meltblown line has resulted in the capability to produce fine fiber meltblown media. The new line can process polymers at temperatures up to 600 degrees Fahrenheit (316 degrees Celsius) and has process air and suction capability to handle the full range of possible substrates.

In addition to the 24-inch wide system, the new laboratory also has a completely refurbished 6 in. meltblown system capable of lower capacity trials for unique polymers and additives. For companies wishing to develop, test and measure statically-charged media, the lab has off-line electrostatic charging capability and the ability to add liquid additives for hydrocharging and surfactant coatings.

Other available process machines include: Mathis Padding and Coating, Sonicated Spray Coating, Slitter/Winder capability, and an SDL Atlas Universal Carding Machine.

Testing services offered by the UGA laboratory include: Filtration Efficiency and Pressure Drop (TSI Model 8130A), Air Permeability (Textest Model FX3300), Absorbency Testing System, Basis Weight and Thickness, Bending Length, charge measurement and longevity tester, Dynamic Mechanical Analysis with Tensile Properties, Elemental Composition and Chemical Structural Analysis (FITR, NMR and XRD), Fiber Diameter and Distribution, Hydrostatic Head (Textest Model FX3000), Polymer /Fiber/Textile characterization, Porosity and Pore Size measurement and Scanning Electron Microscope Photometry (SEM/EDX).

Sustainable System Solutions for Filtration Requirements

Sustainability, quality and efficiency are requirements for systems solutions for filtration applications and their end products. These requirements are covered by the Oerlikon Nonwoven product portfolio, and the company will be showcasing its meltblown and spunbond portfolio at the upcoming FILTECH in Cologne in February next year.

In the case of its hycuTEC hydro-charging solution, Oerlikon Nonwoven offers a new technology for charging nonwovens that increases filter efficiency to more than 99.99%. For meltblown nonwovens producers, this can mean material savings of 30% with significantly superior filter performance. Due to its extremely low water and energy consumption, the hycuTEC is also a future-proof, sustainable technology, as the process can be used without any additional drying steps in the case of most applications.

The bio-based polymer PLA (polylactic acid) is the perfect alternative for those wanting to manufacture sustainable nonwovens. And the Oerlikon Nonwoven meltblown and spunbond technologies are ideally suited for processing PLA.

Spunbond products are becoming increasingly important in filtration applications – as backing materials for filter media and as the filter media themselves. The fact that the nonwoven structure can be tailored to specific tasks enables targeted, customer-specific requirements for various functions to be realized. And combining various functions in a single layer is also possible.

The bi-component spinning process enables the creation of completely new nonwoven structures and hence the incorporation of various functions in a single material. The bicomponent spinning process permits various fiber cross-sections, while standard virgin polymers, bio-based polymers and recycled polyester can be used as raw materials.

Autoneum Offers Recyclable 100% Polyester Carpet Systems

Automotive carpets are typically multi-layered systems that can be challenging to recycle. By introducing a carpet made of 100% polyester, Autoneum now opens up new opportunities for vehicle manufacturers to meet their ambitious sustainability targets. The innovative carpet systems are fully recyclable, paving the way for an improved and more sustainable end-of-life recycling of electric vehicles. In addition, the high content of recycled PET as well as the zero waste and less energy-intensive production process further improve the carbon footprint of Autoneum’s new monomaterial needlepunch and tufted carpets.

Autoneum’s new environmentally friendly carpet systems made of 100% polyester feature a high content of recycled raw materials. Their zero waste and latex-free manufacturing process also significantly reduces CO2 emissions as well as water and energy consumption.

While the interior of cars with combustion engines is usually shredded together with other parts – mainly the vehicle body –, thus making the reclaiming of textile products such as carpets practically impossible, electric cars open up new perspectives for end-of-life recycling. Since the battery has to be removed at the end of vehicle life in order to be recycled or disposed of properly, the demand for easy-to-dismantle products, especially carpets, for the interior of electric vehicles is increasing. However, such easily removable components not only facilitate access to the battery, but they can also be individually recycled at the end of product life, enabling car manufacturers to tap into previously unexploited sustainability potential.

Autoneum’s fully recyclable carpet systems ensure a closed material loop and are thus tangible proof of the company’s long-term commitment to improving the sustainability performance of its products and manufacturing processes. The 100% polyester carpets build on the existing lightweight and particularly sustainable Autoneum Pure technologies: the carpet surface, for example, is made of Di-Light or Relive-1, while Hybrid-Acoustics PET is used for the decoupler. Thanks to Autoneum’s innovative alternative backcoating (ABC) process, which uses a thermoplastic adhesive instead of latex, the production of the new monomaterial needlepunch and tufted carpets also requires significantly less energy and no water at all.

Autoneum’s sustainable tufted carpet system made of 100% polyester is already in development for an electric model of a German vehicle manufacturer that will be available in Europe and Asia.

Claros Technologies Announces Breakthrough Performance of Antimicrobial Textile Additives

Claros Technologies, Inc. announced the release of a third-party independent study verifying the capability and durability of the company’s antimicrobial additives for textiles.

Conducted by an independent laboratory, the test found that Claros’ ZioShieldTM (antimicrobial) and ZioFreshTM (anti-odor) products can reduce the presence of numerous species of disease-inducing bacteria, fungi, and viruses by 99.999 percent, i.e. a log 5 microbial reduction.

While other textiles can possess antimicrobial properties, these textiles have proven to exhibit gradual decreases in performance after regular wash and dry cycles. This decline in performance has also been associated with the loss of up to 70 percent of the textiles’ active ingredients including silver and copper, which then contribute to water and environmental pollution when they are subsequently released into local waste streams.

However, the study found that the textiles that were treated with Claros’ eco-friendly ingredients and processes maintained their log 5 antimicrobial reduction capacities after 100 wash and dry cycles, far surpassing the industry standard of 20 cycles.

Claros has previously received multiple accolades for its advancements in functional textiles. Most recently, Claros was recognized with the 2021 Innovation Award on behalf of TechConnect. Claros also received an International Achievement Award from the Advanced Textiles Association for the company’s ability to significantly increase the safety and longevity of textile composite materials by growing active materials within host fabrics including natural fibers, synthetic fibers, plastic films, and resins. In 2020, Claros was additionally honored with the Tekne award in the category of Sustainable Resources on behalf of the Minnesota Technology Association.

Lear Corp. Launches Sueded Material From Recycled Plastic Bottles

Lear Corporation, a global automotive technology leader in Seating and E-Systems, announced the company’s premium and fully recyclable ReNewKnit™ sueded material will launch in seating and door panel applications with a global automaker in 2024.

ReNewKnit™ is a Lear exclusive, first-to-market automotive textile that is fully recyclable at its end of life. Manufactured solely with recycled materials at Lear facilities using 100% renewable electricity, ReNewKnit™ further strengthens the company’s sustainable solutions technology portfolio while supporting our carbon reduction goals.

Composed of 100% recycled plastic bottles, ReNewKnit™ fibers are spun from polyester yarn and finished with a foam-free, recycled fleece backing that further reduces water and energy consumption in the manufacturing process.

The premium material challenges perceptions of reused and recycled textiles with a wide range of surfaces suitable for various interior applications and improved functionality.