In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: July 29, 2021

Unifi’s REPREVE receives First Higg MSI Scores; showing significant reduction in global warming potential over other fiber types

REPREVE recycled fiber, made by Unifi, Inc. has received its Higg Materials Sustainability Index (Higg MSI) scores, showing that REPREVE reduces the global warming potential by 21% compared to generic, mechanically recycled polyester and 42% compared to conventional virgin polyester.

The Higg MSI (version 3.2) is the most comprehensive tool for sustainability analysts, designers and product developers who want to make more informed materials choices. The Higg MSI global warming potential is related to greenhouse gases. Based on the score, REPREVE is verified to have a lower carbon footprint than comparable materials. By using REPREVE, organizations and consumers can greatly reduce their environmental impact compared to using generic rPET (recycled Polyethylene Terephthalate), one of the most commonly used plastics in the world. Additionally, REPREVE is the only eco-performance fiber with U TRUST verification to certify recycled content claims.

“We continue to build on our commitment to transparency by having the results of our REPREVE Life Cycle Assessment verified and accepted into the Higg MSI,” said James Cooper, Unifi Sustainability Manager. “REPREVE manufactured in the U.S. has a lower global warming potential than standard rPET, providing our customers with a verified pathway to lower their environmental impact and meet their sustainability goals.”

The Higg MSI scores are used to communicate credible data about a product’s performance and validate sustainability progress. These results serve as a public scorecard for sharing the profile and data of a product’s environmental impact, which provides designers and consumers alike with information to make sustainability-based purchasing decisions.

A Life Cycle Assessment (LCA) tool measures the environmental impacts over the whole life cycle of a product or service, including emissions and consumption of material resources. In addition, it provides a more accurate estimate of environmental trade-offs that allows organizations to use more reliable and transparent data to prioritize impact reduction in products and services. The Higg MSI scores are based on an LCA reviewed by the global, multi-stakeholder nonprofit alliance for the consumer goods industry, Sustainable Apparel Coalition, and its technology partner, Higg Co.

Source: unifi.com

Baldwin to introduce TexCoat G4 fabric finishing system to U.S. textile industry at Techtextil North America

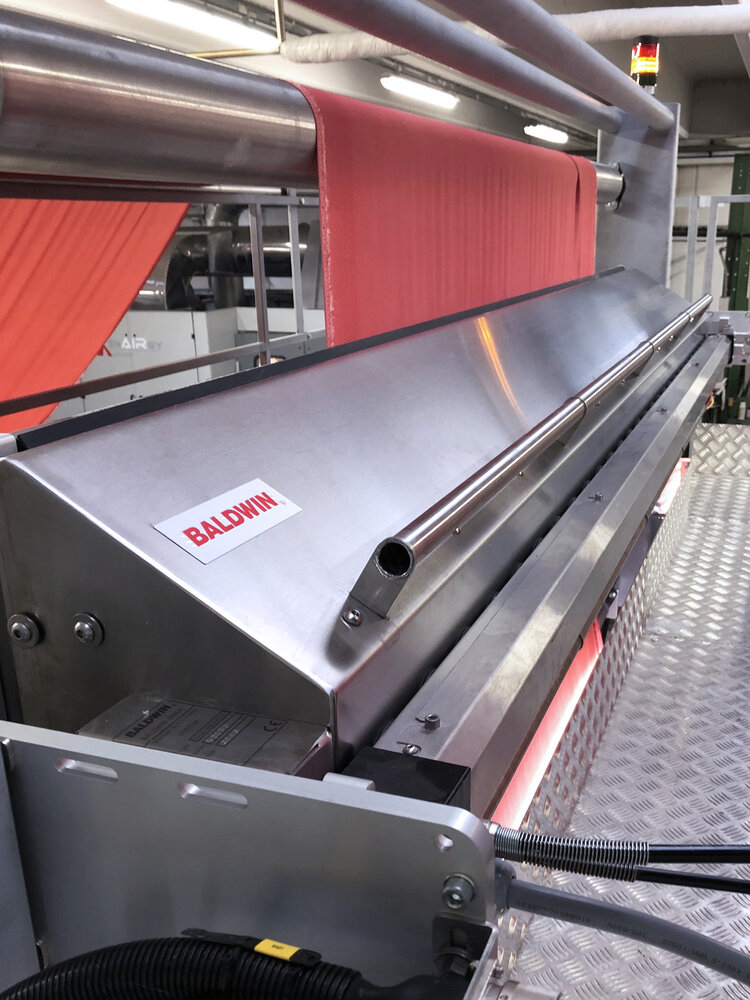

Baldwin Technology Company Inc. will showcase the TexCoat G4 non-contact precision spray fabric finishing system at the Techtextil North America tradeshow, August 23-25, 2021, in Raleigh, North Carolina. The TexCoat G4 provides consistently high-quality fabric finishing, with no chemistry waste, and significantly reduced water and energy consumption.

“We are extremely proud to introduce the TexCoat G4 to the American textile industry,” said Rick Stanford, Business Development Leader at Baldwin. “After receiving incredibly positive reviews during the launch at ITMA 2019, the TexCoat G4 has proven its efficiency for textile manufacturers across Europe and in North and Central America. We are confident in meeting American manufacturers’ high demands for profitability and sustainability, with great margins.”

Baldwin’s non-contact spray technology eliminates chemistry dilution in wet-on-wet processes. The TexCoat G4 consistently and uniformly sprays chemistry across the fabric surface and applies it only where needed, on one or both sides. Customers can expect no bath contamination during the finishing process, as well as minimal downtime during changeovers, which are made easy with recipe management that includes automated chemistry and coverage selection.

The TexCoat G4 also enhances sustainability by wasting no chemistry during color, fabric or chemistry changeovers, and because only the required chemistry volume is applied to the fabric, wet pick-up levels can be reduced by up to 50 percent—leading to 50 percent less water and energy consumption. Furthermore, in single-side applications, drying steps can be eliminated for various textiles, including those that are back-coated and laminated, thereby streamlining and simplifying the production process.

Source: baldwintech.com

Registration opens for RISE Conference 2021

Registration is now open for the RISE (Research, Innovation & Science for Engineered Fabrics) Conference, which will be presented virtually, Sept. 28-30. Once again co-organized by INDA, the Association of the Nonwoven Fabrics Industry, The Nonwovens Institute, and North Carolina State University, the event expects to attract 150 professionals in product development, materials science and new technologies.

The conference will focus on topics including: Sustainability in Material Inputs and End-of-Life Performance, Government/NGO Challenges to Single-Use Plastics, and Market Intelligence and Economic Insights Post-Pandemic. It will also feature the 2021 RISE® Innovation Award, recognizing problem-solving innovations that advance the nonwovens industry.

Featured presentations include:

“Promising Materials Development Using PLA”

presented by Behnam Pourdeyhimi, Ph.D., William A. Klopman Distinguished Professor and Executive Director, North Carolina State University, The Nonwovens Institute

“Phantom Platform: The Polyolefin-cellulose Coformed Substrates Technology at Its Best,” featuring insights from Fabio Zampollo, CEO, Teknoweb Materials S.r.l.

“Biotransformation Technology in Polyolefin Fibers and Nonwoven Fabrics, Focus on Fugitive Used Articles”

with speakers, DeeAnn Nelson, Ph.D., Development Program Manager, and Nick Carter, Vice-President of Marketing and Business Intelligence, both from Avgol Nonwovens

“High-Loft, Ultra-Soft Hygiene Solutions,”

presented by Paul Rollin, Ph.D., Global Team Lead – Nonwovens, ExxonMobil Chemical Company

“Innovating a Sustainable Future for Nonwovens; A European Perspective”

given by Matthew Tipper, Ph.D., Operations Director, Nonwovens Innovation & Research Institute Ltd., (NIRI), UK

“Filtration Media Functionalized with Zinc Oxide”

by Wai-shing Yung, Ph.D., Technical Director, Ascend Performance Materials

For the full RISE program, speaker biographies and other updates, see riseconf.net/index.html.

Source: inda.org

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry. International Fiber Journal is owned by INDA (inda.org).

H.B. Fuller, Covestro partner to deliver environmentally friendly adhesives to the textile industry

H.B. Fuller, a global adhesives provider, announced a strategic partnership with Covestro, one of the world’s largest polymer suppliers, to deliver an adhesive with a reduced climate impact for the woodworking, composites, textiles and automotive industries.

The new ingredient used in H.B. Fuller’s adhesive is a bio-attributed raw material created via a mass balance approach and will replace a proportion of previous fossil raw materials. Renewable raw materials are used as feedstock at the very beginning of the value chain and processed together with fossil-based ingredients in the same production units. The characteristic of the renewable feedstock process is then attributed to the end-product.

The usage of an equivalent amount of the alternative feedstock is guaranteed by Covestro through a third-party verified certification method. By gradually converting its production to alternative raw materials and working with reliable partners, who in turn collaborate with many certified suppliers, Covestro aims to replace fossil materials and make its value chains more sustainable. As mentioned, the correct raw material balance, the allocation method, and the raw material sourcing – according to defined sustainability standards – is ensured via an independent third-party certification.

H.B. Fuller is able to use the new drop-in solution immediately in its existing manufacturing processes without any technical conversion. No adjustments are required at its customers’ facilities either. Product quality is in no way inferior to conventional counterparts, but the lower attributed CO2 footprint makes products more sustainable. In fact, the company has made sure that its customers’ own products and processes will not be compromised in any way. The ‘reformulation’ of the reactive hot melt adhesive has no impact on its performance, nor on their customers’ own manufacturing and can be treated in exactly the same way as the product it replaces.

The new solution represents an evolution of previous sustainable product development and will likely extend into other products and areas of production. Iñaki Sigler concludes, “We believe that any way CO2 emissions can be reduced should be embraced, no matter how small, because many small steps can add up to a strong economy of scale and a giant leap forward for the adhesives industry.”

Both companies believe that the strategic agreement and the innovative process they are now launching together can play a major role in driving the circular economy forward, reducing carbon emissions and replacing the extraction of finite resources with partly renewable raw materials.

Source: hbfuller.com

Glatfelter to acquire Jacob Holm

Glatfelter Corporation has entered into a definitive agreement to acquire Jacob Holm, a global manufacturer of spunlace nonwoven fabrics for critical cleaning, high-performance materials, personal care, hygiene and medical applications. The deal is valued at approximately $308 million, including the extinguishment of debt and subject to post-closing adjustments.

Jacob Holm offers high-performing spunlace nonwoven technologies and advanced fiber-based sustainable solutions that will meaningfully increase Glatfelter’s diversification into attractive and complementary segments serving the growing wipes, healthcare and hygiene categories. With the acquisition of Jacob Holm, Glatfelter will acquire four additional manufacturing facilities and six sales offices located in the Americas, Europe, and Asia, and approximately 800 employees world-wide. Jacob Holm’s broad product offerings and blue-chip customer base will expand Glatfelter’s portfolio to include surgical drapes and gowns, wound care, facemasks, facial wipes and cosmetic masks.

The acquisition of Jacob Holm’s Sontara business, a leading brand of finished products for critical cleaning wipes and medical apparel, will also enhance Glatfelter’s technological capabilities. Jacob Holm generated approximately $400 million in revenue and about $45 million of EBITDA on an LTM basis as of June 30, 2021, supported by strong pandemic tailwinds. Glatfelter believes Jacob Holm’s June LTM results include a benefit from COVID-related demand estimated to be between $10 million and $15 million of EBITDA. Glatfelter expects to realize

annual cost synergies of approximately $20 million within 24 months of closing and is committed to deleveraging its balance sheet following the consummation of this transaction.

“Today’s announcement represents another significant step forward in Glatfelter’s transformation. The combination of Jacob Holm’s quality spunlace and advanced fiber products along with Glatfelter’s industry-leading airlaid and composite fibers products will provide a best-in-class suite of nonwovens technologies, applications, and expertise to serve customers’ growing global demand. By acquiring Jacob Holm, we will further diversify our nonwovens and substrate offerings and enhance our overall innovation capabilities,” said Dante C. Parrini, chairman and CEO of Glatfelter.

The transaction is subject to the satisfaction of customary closing conditions, including receipt of required regulatory clearances, and is expected to be completed later this year. Glatfelter has obtained committed financing for this transaction from HSBC Securities (USA) Inc. and intends to fund the acquisition with unsecured debt. Glatfelter will also pursue extending the maturity date of its syndicated revolving credit facility.

Source: glatfelter.com

Monforts customers showcase sustainable tech at Première Vision Digital Denim Week

Denim manufacturers employing Monforts technologies showcased sustainable fabric manufacturing solutions, featuring advances in fibers, dyes and chemicals, as well as process and supply improvements and recycling options.

The key vertically-integrated users of Monforts equipment present at Première Vision Digital Denim Week included AGI Denim (Pakistan), Azgard 9 (Pakistan), Berto (Italy), Bossa (Turkey), DNM (Turkey), Kilim (Turkey) and Orta (Turkey).

The new Naveena Denim Mills (Pakistan) Holistic collection, for example, employs a suite of sustainable materials such as organic cotton and post-consumer and post-industrial waste cotton that has been shredded and recycled at its in-house unit in Pakistan.

Hemp and Tencel provide sustainable and aesthetic qualities to the collection and the company is replacing conventional elastane with Roica’s Cradle-to-Cradle certified degradable option and polyester with CiClo – a material developed by re:newcell of Sweden that repurposes discarded cotton textiles, such as worn-out denim jeans, through a process akin to recycling paper.

According to Première Vision experts, denims featuring blends with bio-sourced fibers such as nettle and kapok are now being used to attain softer handles, a lighter feel and natural waterproofing, avoiding the need for additional finishing treatments.

Supply chain transparency is also becoming increasingly important, and Turkey’s Bossa is now sharing information on its dyes, energy sources and recycled content use with its customers. For organic cotton in particular, Bossa provides QR codes with which brands can identify the names of individual farms and their locations, as well as details such as the origins of specific seeds and the use of irrigation by growers.

Turkey’s Orta’s new Denim Route – inspired by the historical Silk Road for trade between the East and West – is an interactive supplier map detailing the regions from which it sources cotton, dyestuff, chemicals and various fibres to complement its other transparency initiatives.

Via a dedicated app, the Denim Route shares three years’ of LCA (life cycle assessment) data on each of the company’s fabrics featured. By scanning the QR code on a product’s hangtag, users can pull up the data for detailed information.

More than just a label saying that garment are ‘ethically-made’ or ‘sustainably-sourced,’ transparency of sourcing back to the first steps of the supply chain, the processes and the companies involved are becoming a consumer mandate, the company says.

Meanwhile, a living and breathing piece of clothing that absorbs carbon dioxide while simultaneously producing oxygen was introduced at Digital Denim Week 2021 by Azgard 9 (Pakistan) .

Treated with microbial pigmentation, this garment – which is currently being analysed by all of the company’s global customers, from large luxury fashion groups like LVMH to fast fashion brands like Zara – basically behaves like a plant or tree.

During its life cycle, it will improve the immediate environment of the wearer and produce approximately the same amount of oxygen as an oak tree. In addition, the garment is water resistant and breathable, with advanced antimicrobial and anti-odor properties.

Source: monforts.de

FET installs new spunbond system at University of Leeds

Fibre Extrusion Technology Ltd, UK has completed the installation and commissioning of a new FET Laboratory spunbond system for the University of Leeds.

The FET spunbond system is now an integral part of the research facilities of the CCTMIH (Clothworkers’ Centre for Textile Materials Innovation for Healthcare), led by Prof. Stephen Russell based in the School of Design, University of Leeds, who commented, “The new spunbond system is perfectly suited to our academic research work, and is already proving itself to be extremely versatile and intuitive to use”.

This spunbond system complements existing research lab facilities at the university, which covers all areas of fiber and fabric processing, physical testing and characterization. It forms part of a wider investment in facilities to support fundamental, academic research on ‘future manufacturing’ for medical devices, where the focus is on studying small-scale processing of unconventional polymers and additive mixes to form spunbond fabrics with multifunctional properties.

Key to this research is developing the underlying process-structure-performance relationships, based on the measured data, to provide detailed understanding of how final fabric performance can be controlled during processing.

As a rule, many exciting materials developed in academic research struggle to progress beyond the bench, because of compatibility issues with key manufacturing processes such as spunbond. By leveraging mono, core-sheath and island-in-the-sea bicomponent technology, the Leeds University team is working with polymer and biomaterial research scientists, engineers and clinicians to explore the incorporation of unusual materials in spunbond fabrics, potentially widening applications.

FET has built on its melt spinning expertise to develop a true laboratory scale spunbond system and is currently working on a number of other such projects globally with research institutions and manufacturers.

Source: fetuk.com

European Commission opens study on unintentional release of microplastics

The European Commission (DG Environment) has commissioned a study entitled “Cost-benefit analysis of policy measures reducing unintentional releases of microplastics.” The study aims to identify policy options that could reduce unintentional releases of microplastics in the environment. The study will support the commission’s work on a possible legislative initiative.

Communication and engagement activities will allow the study to gather available information and will allow stakeholders to provide input. The first stakeholder workshop will take place virtually on September 16, 2021. Stakeholder registration is now open.

Source: ec.europa.eu

Lenzing collaborates with Orange Fiber as part of new TENCEL Limited Edition initiative

Lenzing Group, a global producer of wood-based specialty fibers, is partnering with Orange Fiber, an Italian company which has patented the pulp production process for citrus by-products, to produce the first ever TENCEL branded lyocell fiber made of orange and wood pulp. This new product aims to realize both companies’ shared vision to enhance sustainability in the textile and fashion industry.

According to Lenzing, the TENCEL Limited Edition in partnership with Orange Fiber presents a novel cellulosic fiber to further inspire sustainability across the industry value chain and push the boundaries of innovation. The fibers are currently being transformed into a new collection of fabrics which Orange Fiber will present to the market in October 2021.

Collections produced from TENCEL Limited Edition with Orange Fiber will have dedicated marketing materials, such as special edition co-branded swing tags, which will provide relevant information about the process of production and materials involved. The goal is to encourage co-development of innovative solutions to give waste a new life and promote greater transparency in the textile and fashion industry to fully achieve sustainable industry practices.

Source: tencel.com

Owens Corning acquires vliepa GmbH; broadens portfolio in nonwovens

Owens Corning announced it has acquired vliepa GmbH, which specializes in the coating, printing and finishing of nonwovens, paper and film for the building materials industry. The acquisition broadens Owens Corning’s significant global nonwovens portfolio to better serve European customers and accelerate growth of building and construction market applications in the region.

“This highly complementary combination advances our global strategy of expanding deeper into the value chain and investing in high-growth markets,” said Marcio Sandri, president of Owens Corning’s Composites business. “The acquisition adds immediate coating capacity for our customers in the building materials industry, along with supporting the transformation of the construction market from traditional materials to innovative, glass-faced solutions.”

With this transaction, Owens Corning has taken ownership of two production facilities in Brüggen, Germany. Terms of the transaction were not released.

“I am very excited about our new opportunities with Owens Corning,” said Eric Schillings, managing partner of vliepa GmbH. “Leveraging their broad enterprise capabilities and market-leading positions, Owens Corning will help us expand in our markets and accelerate our growth. I am confident that vliepa will have a bright future in the new organization.”

The acquisition reinforces Owens Corning’s commitment to its global nonwovens business.

Source: owenscorning.com

Kimberly-Clark’s Scott 24 wins World of Wipes Innovation Award

Kimberly-Clark Professional’s Scott 24-hour sanitizing wipes won the Innovation Award at the World of Wipes conference, July 12-15 in Atlanta. Scott 24 is the first pre-saturated wipe capable of quickly disinfecting and maintaining surface sanitization for 24 hours, killing 99.9% of bacteria, such as staphylococcus aureus, enterobacter aerogenes and community-associated methicillin resistant staphylococcus aureus bacteria. The wipes patented formulation is found to be effective by the U.S. Environmental Protection Agency for disinfecting on hard, non-porous surfaces against numerous strains of bacteria and viruses, including SARS-COV-2, when used as directed.*

Scott 24 is unique in the pre-saturated wipes category because it is capable of killing germs on surfaces for 24 hours after its initial application, regardless of the number of touches. The technology is the first pre-saturated wipe to pass the EPA’s residual surface-sanitization protocol. This protocol requires that coatings withstand a series of both wet and dry abrasions and inoculation with bacteria in order to ensure the ability to kill 99.9% of bacteria over a 24-hour period, in spite of multiple touches.

While the core of the invention is in the chemistry, much care was taken in the development of a specialized base sheet to deliver it:

- The solution is delivered via a meltblown wipe treated with its own proprietary blend of chemistry that minimizes quat binding.

- Kimberly-Clark’s meltblown process delivers a structure that combines optimized fibrous surface area and a unique bond pattern to ensure that the formulation is absorbed and distributed throughout the entire pore structure of the material.

- Optimized fluid distribution in the wipe leads to excellent controlled liquid release, which then helps to maximize the number of passes over a surface before the chemical is exhausted.

- Finally, the fiber composition and orientation combined with the unique bond pattern creates a surface topography that allows users to remove soil and provides users with an exceptional cleaning experience.

Other nominees in the WOW Innovation Award program included:

- Lenzing’s Lyocell Skin fibers, which are the basis for a premium facial sheet mask skincare routine that meets the expectations for translucency, smoothness, fineness and comfort.

-

Shark VACMOP by SharkNinja, a cordless hard floor cleaning system that utilizes suction and spray mopping for a more thorough clean. The all-in-one disposable pad uses multiple nonwoven types allowing consumers to pick up and lock away dry debris, and also spray-mop to tackle the toughest messes.

* Scott 24 is not approved in California for use against SARS-CoV-2.

Source: worldofwipes.org

* The World of Wipes conference is produced by INDA, Association of the Nonwoven Fabrics Industry. International Fiber Journal is owned by INDA (inda.org).

John Poccia recognized with INDA Lifetime Achievement Award

The World of Wipes conference, July 12-15 in Atlanta featured the presentation of the INDA Lifetime Achievement Award to John F. Poccia III. Poccia is a longtime participant in the nonwovens industry, primarily with Johnson & Johnson and more recently as president of Poccia Consulting LLC.

The annual award is nominated by INDA’s Technical Advisory Board and presented to an individual whose technical achievements over a long-standing career have significantly contributed to the technical advancement, success, and growth of the nonwovens industry. “John is a stellar technical professional and contributor to our industry. His 40-plus year technical career includes a broad range of advancements in material science synthesizing superabsorbent polymers, and end-products of feminine hygiene, wipes, wound management and skincare at Johnson & Johnson Company. His efforts have advanced the nonwovens industry and INDA,” said Dave Rousse, president of INDA.

Poccia’s career highlights include:

- BS Degree in Chemistry, Rutgers University 1982

- 2015-2018 INDA Board of Directors

- WOW and Hygienix Conference Committees

- INDA Technical Advisory Board

- Advisory Board Member Nonwovens Institute, North Carolina State University and served as technical advisor for many sponsored projects

- 2017 – The Fiber Society – Created the Johnson & Johnson Graduate Student Award for outstanding work in the area of fiber science

- Over 30 patents in fields ranging from hygiene, medical devices, skincare, wound management, and baby/adult wipes

Source: worldofwipes.org

* The World of Wipes conference is produced by INDA, Association of the Nonwoven Fabrics Industry. International Fiber Journal is owned by INDA (inda.org).

HeiQ, Lycra partner to deliver textile solutions in stretch, thermoregulation, freshness & sustainability

HeiQ and The Lycra Company have entered into a collaboration across multiple technology and brand platforms that aims to bring more innovative, quality-enhancing and sustainable textile technologies to consumers in the stretch, thermoregulation, freshness and sustainability market spaces. The Lycra Company is a leader in branded fibers and fabrics addressing the stretch, warming and cooling market spaces, while HeiQ is an innovator in finishes for freshness, sustainability, smart temperature management, antiviral, dryness, and related market spaces.

The initial in what is expected to be several rollouts from this partnership will happen through the summer, with HeiQ freshness and antiviral benefits provided through Lycra’s stretch fabrics under a new brand, LYCRA freshFX. Preparation for this innovation is underway, with an initial focus on Chinese local value chains for the Chinese consumer, and the introduction is earmarked for the Intertextile show in Shanghai at the end of August.

“We are pleased to announce the launch of this collaboration, the culmination of conversations that began two years ago,” said Steve Stewart, chief brand and innovation officer at The Lycra Company. “By combining the strength of both companies, we will continue to drive meaningful innovation within the textile industry, delivering new solutions at a quicker pace to a broader audience.”

“Our goal at HeiQ is to enable brands and mills in the textile industry to bring more comfort, performance and sustainability to textile products while raising brand awareness with key consumers who will benefit the most from these innovations,” said Carlo Centonze, co-founder and CEO of HeiQ Group. “This collaboration with The Lycra Company not only brings the best minds together but also ensures our breakthrough innovations will be available for and benefit as many consumers as possible.”

Sample fabrics and garments will be available in late summer for commercial selection.

Source: heiq.com

Price Hanna Consultants releases new report on spunbond, spunmelt & meltblown nonwoven markets

Price Hanna Consultants LLC has published a new report to provide global and regional market information on spunbonded, spunmelt and stand-alone meltblown nonwoven polypropylene capacity, demand, manufacturing costs and profitability through 2025.

From 2015 to 2020, global nameplate fine and coarse denier capacity increased 23.4% over 2015. Average annual capacity growth during the period was 4.3%. Merchant market capacity grew at a rate of 5.2%. Based upon capacity expansions already completed or announced, global fine and coarse denier capacity will increase about half that commissioned during the prior five-year period but will grow larger before 2025. Price Hanna also finds hygiene demand continuously growing in consumption, with the positioning of new plants and capacity in India and Africa supporting this growth in developing markets.

The report provides new findings on the following topics:

- Perspective on regional and global capacity development from 2015 – 2025 and estimates of supply/demand by global region for each year from 2020 – 2025.

- Estimates of imports and exports by region and their impact on regional capacity utilization.

- Analysis of regional output capacity capable of supplying modern hygiene end uses by individual machine and in total by producer and region as compared to regional demand.

- Cost-of-manufacture estimates for selected leading regional producers using the latest generation technology based on estimates of Q1 2021 polypropylene costs.

The report provides information on capacity by producer, country and location, line, technology, and beam configurations and compares regional and global supply to demand. It is available as a hard copy or electronic PDF.

Source: pricehanna.com

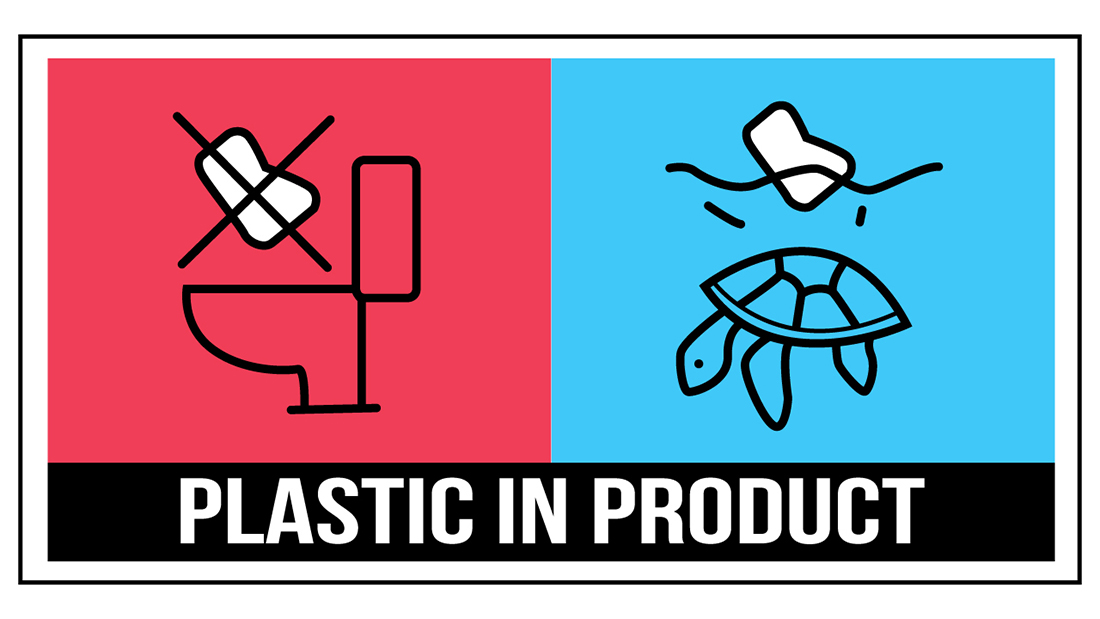

EDANA, manufacturers of wet wipes commit to revised package labeling and awareness campaigns

EDANA, the Europe-based association representing the nonwovens industry, and its member manufacturers of wet wipes have committed to revise package labeling to further raise consumer awareness on types of wipes and disposal methods. This commitment will also see EDANA and pertinent members lead national awareness raising campaigns in the UK and a number of selected EU countries, beginning with the Netherlands in 2022.

“Our sector has long been active in trying to address the serious problem caused by marine litter and of the role the industry has a duty to play in helping tackle it,” noted the association. “In fact, EDANA has already invested in efforts to reduce wet wipe litter, raise consumer awareness on correct disposal, adopt a Code of Practice for labelling wet wipes and produce wipes that do not impact sewers. Now increased efforts, in conjunction with key stakeholders, and centered on a sound, science-based and collaborative approach can greatly help progress in this direction.”

More details on EDANA’s planned packaging revisions and awareness campaigns are available here.

Source: edana.org

Indorama announces new facility in Indonesia to recycle 2 billion PET bottles annually

Indorama Ventures Public Company Limited (IVL) announced it will build a facility in Karawang, West Java, to recycle 1.76 to 1.92 billion polyethylene terephthalate (PET) plastic bottles annually and create 217 new jobs. The facility is part of IVL’s global commitment to divert post-consumer PET bottles away from waste and back into the circular economy, supporting the Government of Indonesia’s National Plan of Action on Marine Plastic Debris. The recycling plant will provide washed and shredded post-consumer bottles as PET flake feedstock to produce recycled resin that is suitable for food contact use.

Source: indoramaventures.com

Indorama adds PNDA production unit in Decatur, Alabama

Indorama Ventures Xylenes & PTA, LLC (IVXP) announced a new Purified 2,6-Naphthalene Dicarboxylic Acid (PNDA) production unit. The unit is located at IVXP’s manufacturing site in Decatur, Alabama.

PNDA is the carboxylic acid counterpart to NDC (naphthalenedicarboxylate), which is also produced at IVXP’s Decatur facility. The product is produced as a white solid powder and is used to make specialty polyester polymers for electronic and electrical parts, packaging, high-temperature performance polymers, chemical intermediates, as well as liquid crystal chemicals and polymers. PNDA maintains a 99.8% purity level, with low levels of metals and other organics.

Source: indoramaventures.com

Bestseller invests in Infinited Fiber Company’s textile-to-textile technology

Infinited Fiber Company has secured €30 million in new financing and Bestseller’s investment arm Invest FWD is among the group’s new investors. The company’s technology turns cellulose-based raw materials, like cotton-rich textile waste, into Infinna, a biodegradable fiber that contains no microplastics and can be recycled in the same process together with other textile waste.

“Through our ongoing collaboration, we have developed the first prototypes and seen that the fiber can live up to our requirements for quality, look and sustainability,” says Camilla Skjønning Jørgensen, Bestseller’s Sustainable Materials & Innovation Manager, who heads Fashion FWD Lab. “With Infinited Fiber Company’s planned flagship factory, we can actually scale this amazing circular material and, in time, make it a competitive fiber to conventional fibers.”

Bestseller has also signed a multiyear sales agreement for the Infinna fiber following a year of collaboration to look at the potential to put the fiber into production.

“For us, this is much more than an investment,” said Jørgensen. “This is a pathway to change the environmental impact of the fashion industry, as it provides a technology solution that makes textile-to-textile recycling possible. At the same time, this is something that represents the potential for Bestseller to reach our North Star and become circular by design. And most importantly: this is only the beginning.”

Besides Invest FWD, other investors in this round of financing include sportswear company Adidas, investment company Security Trading Oy, as well as existing investors H&M Group and investment company Nidoco AB.

“We are really happy to welcome our new investors and grateful for the continued support from our older investors,” says Infinited Fiber Company co-founder and CEO Petri Alava. “These new investments enable us to proceed at full speed with the pre-engineering, environmental permits, and the recruitment of the skilled professionals needed to take our flagship project forward. We can now also boost our pilot facilities so that we can better serve our existing customers and also grow our customer-base in preparation for both our flagship factory and for the future licensees of our technology.”

Source: bestseller.com

Nominations now being accepted for 2022 IDEA Achievement Awards

INDA, the Association of the Nonwoven Fabrics Industry, and Nonwovens Industry magazine announced the opening of nominations for the prestigious IDEA Achievement Awards, which are part of the IDEA nonwovens and engineered fabrics conference and exposition scheduled to be held at the Miami Beach Convention Center in Miami Beach, Florida, March 28-31, 2022.

The IDEA Achievement Awards recognize leading companies and new innovations in the global engineered fabrics industry in six categories. Nominations are being accepted in the following categories:

- Sustainability Advancement (advances one or more elements of sustainability or circularity since 2019)

- Equipment (best new equipment introduction since 2019)

- Raw Materials (best new raw materials introduction since 2019)

- Short-Life (best new disposable product introduction since 2019)

- Long-Life (best new durable product introduction since 2019)

- Nonwoven Product (best new nonwoven product introduction since 2019)

Submission deadline is January 15, 2022. Selections will be made by members of the industry voting through Nonwovens Industry magazine. Selection of the Entrepreneur Award will be made by Nonwovens Industry magazine.

More details on the IDEA Achievement Awards criteria and eligibility are available at https://www.inda.org/awards/IDEA-Achievement-Award.html

IDEA Achievement Award Winners in 2019 included:

Machinery/Equipment:

A.Celli Nonwovens S.P.A.: A.Celli Vision System (DMS 4.0)

Raw Materials:

Lenzing AG: Veocel™ Lyocell fibers with Eco Cycle Technology

Nonwoven Product:

Fitesa: Fitesa 100% BioBase PLA Softs

Short-Life Converted Product:

Callaly: Tampliner®

Long-Life Converted Product:

Soteria Battery Innovation Group: Soteria Battery Architecture

Entrepreneur:

P&G Venture Labs

Source: inda.org

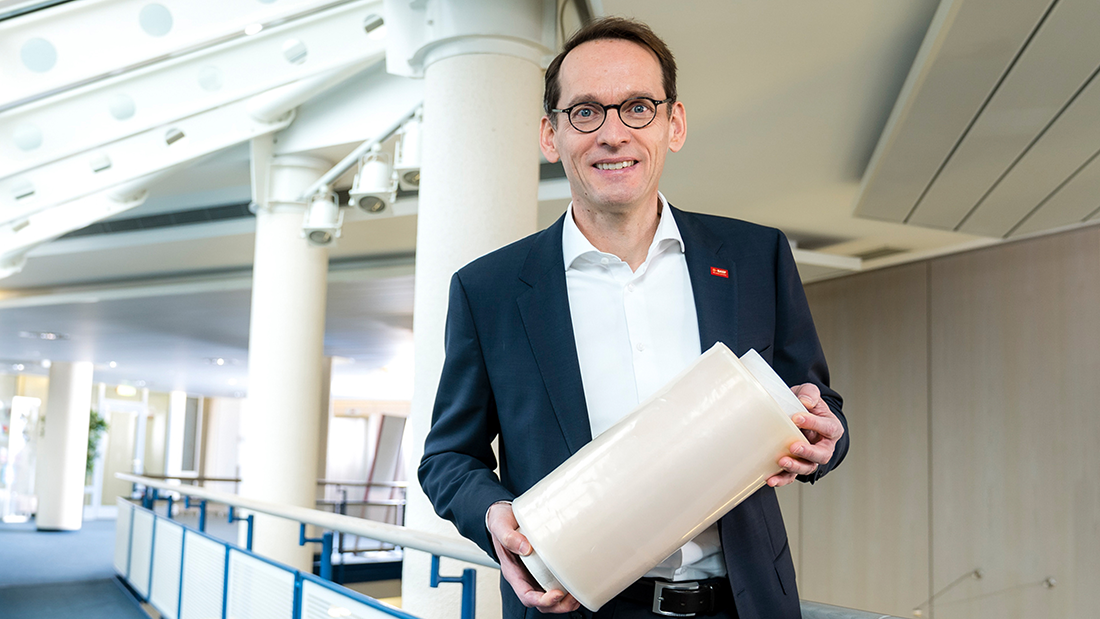

BASF introduces VALERAS, a new sustainable brand for its plastic additives portfolio

BASF has focused the sustainable solutions of its plastic additives’ portfolio under the new global brand VALERAS. VALERAS aims to increase the sustainability of plastics along the entire polymer value chain. Later this year, the portfolio will expand to include the company’s additive packages for mechanically recycled plastics and their applications.

“The trend towards sustainability has been accelerating, driven by consumer demand and more stringent legislation. Our customers are facing increasing pressure regarding sustainable innovations and challenges of plastics recyclability,” says Dr. Thomas Kloster, president, Performance Chemicals, BASF. “With VALERAS, we create new value for plastics by supporting our customers on their sustainability journey with novel solutions and services. VALERAS shows our broader ambition to establish a platform that covers all our additive solutions that contribute to the sustainability goals of our customers.”

VALERAS includes BASF’s existing plastic additives designed to improve durability, save energy, reduce emissions, and promote biodiversity.

As part of its comprehensive sustainability initiatives, BASF Plastic Additives has also launched a new website www.plasticadditives.basf.com that emphasizes its sustainability solutions and services. Visitors will easily find information organized by industries and applications. Proven customer success stories from various industries, as well as relevant product data, give further insights on best practices. In addition, it also showcases new technologies and innovations that can enable customers to make their own businesses more sustainable.

Source: basf.com

EDANA announces new board members

EDANA, the Brussels-based association serving the nonwovens and related industries, has elected five new governors and confirmed its team of officers for 2021-2022. Mikael Staal Axelsen (Fibertex) remains as chair, supported by continuing vice-chairs Åsa Johansson (Essity, Sweden) and David Lamb (Nonwovenn, UK) and Treasurer Giorgio Mantovani (Corman, Italy). Announced at EDANA’s recent online Annual Strategic Review and AGM, the newly elected board began their term on July 1st.

“EDANA now has over 320 members and a broader reach and wider scope than ever. It is encouraging therefore to welcome such a range of expertise on to our board,” said Mr. Staal Axelsen. “The ongoing member confidence in our assembly to drive our determined and broad agenda is very rewarding. EDANA’s ongoing successful fostering of an environment beneficial to innovation, and to sustainable and profitable growth, is a great testament to the professionalism of the team and our members.

The following governors were elected as new board members:

- Mr Cédric Ballay, CEO, PFNonwovens, Spain

- Mr. Jürgen Eizinger, Vice President of Global Business Management Nonwovens Division, Lenzing, Austria

- Mr. Omar Hoek, Executive Vice President Engineered Papers, SWM, Luxembourg

- Mr. Achim Schalk, Executive Vice President & General Manager HHS EMEIA, Berry Global, Germany

- Mr. Michael Trinkaus, Director R&D and Application Engineering, Mondi, Germany

The team of officers is reinforced by executive governors, co-opted by the board: Mr. Thorsten Habeck (Business Director – Fiber Bonding Europe, Middle East & Africa, BASF, Germany), Mr. Ulrich Hornfeck (Board Member & Chief Commercial Officer, Sandler, Germany), Mr. Krzysztof D. Malowaniec (Senior Vice President, Paul Hartmann, Germany), Mr. Jörg Ortmeier (CEO, TWE Group, Germany) and Mr. Mark A. Thornton (Vice President Global Materials and Packaging, Procter & Gamble, United States).

At the June AGM, special thanks were extended to Mr. Frantisek Klaska (PFNonwovens), who is leaving the EDANA Board of Governors after 20 years.

Source: edana.org