In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: July 31, 2022

Indorama Ventures resumes production of polymers plant in Texas

Indorama Ventures Public Company Limited (IVL), a global sustainable chemical company, announced that construction of an integrated PTA-PET plant in Corpus Christi, Texas, will resume in August 2022.

Corpus Christi Polymers LLC (CCP), a partnership between three companies, is expected to begin production in 2025 and ensure continued cost-competitive production to support the growth of IVL’s global PET operations into the next decade.

CCP was formed in 2018 as a joint venture between Indorama Ventures Corpus Christi Holdings LLC, a subsidiary of Indorama Ventures; DAK Americas LLC, a subsidiary of Alpek S.A.B. de C.V.; and APG Polytech USA Holdings, Inc, a subsidiary of Far Eastern New Century, following the purchase of a partially constructed facility of M&G Resins in Corpus Christi.

Construction of the state-of-the-art plant is resuming following a period of pandemic-related disruptions. Through the pandemic, the partners firmly resolved to continue planning amid continued robust demand for PET packaging and the need for shorter supply chains. As the impact of the pandemic eased in 2022, the management team was strengthened in preparation for the resumption in activities.

The facility will have nominal annual capacities of 1.1 million metric tons of PET and 1.3 million metric tons of PTA, shared between the partners. It will employ three state-of-the-art technologies: PTA: IntegRex®, PET melt: Invista, and PET solid state: Easy Up (HCIRR – Horizontal Continuous slightly Inclined Rotary Reactor).

Source: www.indoramaventures.com

Lenzing partners with Red Points to fight counterfeits

Lenzing Group, a leading global producer of wood-based specialty fibers, announced a partnership with Red Points, a global leader in online IP infringement detection and removal, to strengthen Lenzing’s existing brand protection efforts globally and enable round-the-clock brand monitoring services.

As Lenzing’s textile brands TENCEL™, LENZING™, ECOVERO™, as well as nonwovens brand VEOCEL™ continue to generate widespread demand from industry partners and customers worldwide, it is becoming increasingly important to protect the company’s trademarks and provide full visibility into the brands’ presence online.

Red Points provides the ideal technology solution to help Lenzing monitor and remove unauthorized use of its trademarks and counterfeits online. The technology works by using Artificial Intelligence (AI) to automatically detect intellectual property infringements of Lenzing’ trademarks with high accuracy and efficiency.

Source: www.lenzing.com

Ontex Group NV opens plant in North Carolina

Ontex Group NV, a leading international supplier of personal care products such as baby pants, adult diapers and feminine hygiene products, opened a new facility in Stokesdale, part of Rockingham County in the U.S. state of North Carolina in July.

The new plant currently employs nearly 100 people and manufactures baby diapers for retailers and lifestyle brands. The new plant is planned to expand its production and workforce to also manufacture other product categories. The Stokesdale facility complements Ontex’s plant in Tijuana, Mexico to supply the growing partner brand market in North America.

Source: ontex.com

Flame-resistant pants from Dovetail

Women’s workwear brand Dovetail Workwear recently introduced its first flame-resistant (FR) pants. The pants are available in canvas and denim constructions, and are designed for use among welders, blacksmiths, glassblowers and utility workers within oil, gas, electrical, utility, and heavy industries where the need for electrical arc and flash-flame protection is essential.

The Britt Utility FR Canvas, made with a midweight stretch material, and the Britt Utility FR Denim, made with 10 oz. comfort stretch denim, both offer durability without added weight and are treated with flame- and arc-resistant properties, the brand stated. The heavyweight DX Bootcut is made with 11 oz. FR denim and offers a slim bootcut leg and a mid-rise waist.

All Dovetail FR pants meet safety standards PPE CAT 2, ASTM F106, and NFPA 2112 and 70E, and complies with use across a variety of industrial jobs and DIY projects requiring flash protection. Each pant style offers permanent protection for the life of the garment when consumers follow the manufacturer’s recommended laundering instructions.

Source: www.dovetailworkwear.com

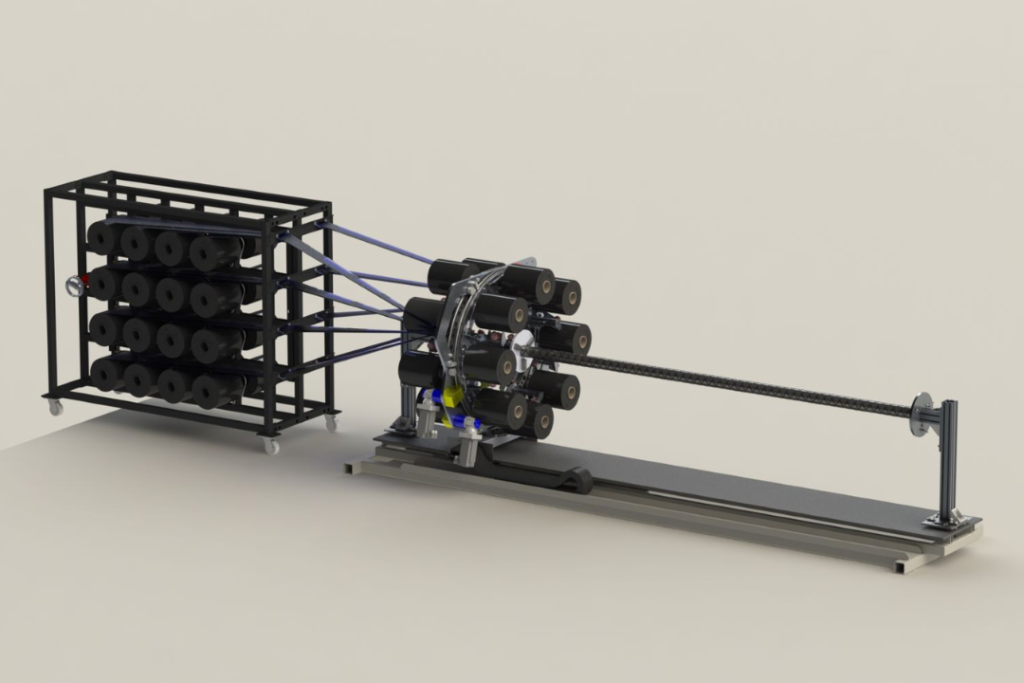

Cygnet Texkimp introduces zero-degree filament winding

U.K. fiber handling and converting technology company Cygnet Texkimp has developed a way of winding composite fibers at a zero-degree angle to create curved and straight structural parts with enhanced mechanical strength using the minimum amount of fiber.

Zero-degree winding — axial, unidirectional or longitudinal winding — is a sought-after technique, particularly among manufacturers of lightweight structural components for the automotive, aerospace and construction industries. The technique exploits the inherent mechanical strength created when fibers are wound straight along the axial load path or the longitudinal axis.

According to Cygnet Texkimp’s Dr. Yan Liu, there are ways of getting close to zero degrees using conventional filament winding, but there is no retaining mechanism to hold the zero-degree fibers in place. Similar properties can be produced by manually pre-wrapping the mandrel, but this is said to be a labor-intensive approach which is unsuitable for high-volume applications.

Zero-degree winding describes the action of laying down the fiber in parallel with the direction of the mandrel axis. Cygnet Texkimp says it has developed the process using its 3D Winder and Multi-Axis Winder machines. Crucially, the capability of these two technologies enables manufacturers to create not only straight parts with zero-degree winding but also curved parts, such as fuel pipes for planes, according to the company.

Source: cygnet-texkimp.com

Carbios strengthens leadership in biorecycling

Scientists at French company Carbios and their academic partner, The Toulouse Biotechnology Institute (TBI) are working on enzymatic research in order to optimize the end-of-life of plastics and textiles.

In an article published in Biophysical Journal they describe the use of Nuclear Magnetic Resonance (NMR) spectroscopy to study the thermal stability of PET depolymerization enzymes and the mechanism of adsorption of the enzyme on the polymer. This innovative approach, which required months of development, is a world first and opens up new ways of improving these enzymes.

Prof. Alain Marty, Chief Scientific Officer of Carbios and co-author of the article, said that nearly 25 researchers are currently working on the company’s unique enzymatic technology.

Dr. Guy Lippens, CNRS Research Director and co-author of the article, added that “Nuclear Magnetic Resonance (NMR) is an extraordinary biophysical technique for visualizing an enzyme directly in solution. Our study is the first to use NMR as a complementary technique to crystallography and molecular modeling to observe a PETase. This gives new perspectives to better understand the functioning of these enzymes and it makes it possible to imagine new ways of improving these enzymes.”

Source: www.carbios.com

New pilot line for textile recycling in Finland

Lounais-Suomen Jätehuolto (LSJH) in Paimio, Finland, has successfully started up a new ANDRITZ pilot line for research and development work on post-consumer textile recycling.

The Exel tearing machine for post-consumer textile waste can process up to 500 kg/h for spinning quality and up to 1 t/h for nonwoven fiber quality. The entire process is designed to ensure the total absence of metallic material in the fibers and remove hard, non-textile items using cleaning devices, highly sensitive metal traps, and metal detectors.

LSJH is a municipal waste management company in Finland specialized in processing post-consumer household textiles into a variety of customized raw materials containing high-quality fibers. As Finland will be the first country in the world to start post-consumer textile collection on a national scale in a few months’ time, the LSJH Paimio recycling facility is the location where large amounts of textile waste will be fed to a sustainable and responsible circulatory solution.

Source: www.andritz.com

Camfil Germany switches to 100% green electricity

Camfil Germany is now using 100% regional green electricity which means that all its air filters and air purification systems are produced entirely with local, renewable energy from sun, wind and hydropower.

By switching to 100% green electricity from regional supplier Stadtwerke Ratzeburg, Camfil Germany reinforces the Swedish group’s overall commitment to reduced CO2 emissions. This is also in line with Camfil’s long-standing membership of the UN Global Compact, and its ten principles promoting sustainability in companies.

Source: www.camfil.com

RISE® returns in-person to North Carolina State University this fall

Nonwovens innovators will convene in-person for RISE® – Research, Innovation & Science for Engineered Fabrics Conference – the industry’s premier conference on nonwovens science and technology, Sept. 27-28 at North Carolina State University in Raleigh.

The 12th edition of RISE returns live to Talley Student Union after being held virtually over the last two years. The event is co-organized by INDA and The Nonwovens Institute at North Carolina State University. Registration is now open at the RISE® website.

Experts in product development, material science, and new technologies will come together for this insightful two-day conference focused on promising technology developments, future needs and market opportunities. Participants will have opportunities to exchange views on innovative nonwoven technologies and applications, furthering INDA’s strategic initiative to connect and convene the industry.

The 2022 RISE® program will focus on breaking developments in responsible sourcing of nonwoven inputs, realistic end-of-life options, and circularity opportunities in the world of nonwovens and engineered materials with thought leaders presenting on these cutting-edge topics.

Innovations that solve problems and advance the nonwovens industry will be recognized with the 2022 RISE® Innovation Award. The award will be presented Sept. 28 in the culmination of the event. Companies can self-nominate products online until July 15. Last year’s winner was the Canopy Respirator, an innovative, fully mechanical, non-electrostatic respirator with a filter designed for superior breathability and wearer facial transparency.

Source: www.riseconf.net

WhiteCycle: A European consortium to recycle plastic waste

The WhiteCycle project, coordinated by Michelin, was launched on Friday, July 1st. Its main goal is to develop a circular solution to convert complex waste containing textile made of plastic into products with high added value. Co-funded by Horizon Europe, the European Union’s research and innovation program, this unprecedented public/private European partnership includes 16 organizations and will run for four years.

WhiteCycle envisions that by 2030 the uptake and deployment of its circular solution will lead to the annual recycling of more than 2 million tons of the third most widely used plastic in the world, PET2. This project should prevent landfilling or incineration of more than 1.8 million tons of that plastic each year. Also, it should enable reduction of CO2 emissions by around 2 million tons.

Complex waste containing textile (PET) from end-of-life tires, hoses and multilayer clothes are currently difficult to recycle, but could soon become recyclable thanks to the project outcomes. Raw material from PET plastic waste could go back into creation of high-performance products, through a circular and viable value chain.

Source: www.michelin.com

AMSilk Announces Plans to Scale-up Production

AMSilk GmbH (“AMSilk”), a world leader in supplying innovative high-performance bio-based silk materials, announced plans to scale-up production capacity by several thousand tons a year and expand its production network outside of Europe.

AMSilk’s scalable biotechnological platform and best-in-class patent portfolio means it is able to produce large quantities of premium bio fabricated silk materials in constant quality.

The company also announced that co-founder and CTO Dr. Lin Römer has stepped down from the management team and Board and will move to a part-time consultancy role supporting AMSilk with his broad and versatile expertise and know-how.

After 14 years at AMSilk, Dr. Römer has decided to pursue new opportunities outside of the company. Over the past decade, he has been dedicated to the success and the growth of AMSilk, and he has been instrumental in bringing its biotech products from the lab to industrial scale, resulting in the successful market launch of the world’s first artificial spider silk products.

Source: www.amsilk.com

France Relance program strengthens stability of B.I.G. Yarns Comines

B.I.G. (Beaulieu International Group) Yarns Comines recently received a delegation of institutional representatives as part of its France Relance program. At the end of 2021, B.I.G. Yarns Comines was selected as one of the laureates for the French government’s Program that is highly focused on accelerating economic growth.

The France Relance program aims to provide financial support to companies after the Covid crisis and ensure the recovery of the economy.

The financial support allowed B.I.G. Yarns to increase the production capacity of its best-in-class 1-step 3-layer PA yarn technology by 20% through the installation of new state of the art production lines at the Comines production site. The new lines utilize B.I.G. Yarns’ cutting-edge PA yarn technology that increases design, contrast and color freedom for carpet tile manufacturers, but also provides increased flexibility. This realization allows customers to respond faster to new developments in the contract market.

In addition to strengthening and renewing its production infrastructure and technology, B.I.G. Yarns also focused on developing new innovative products that contribute to the sustainability efforts of its customers.

For example, B.I.G. Yarns will start producing PET yarns for the first time and will be able to offer a completely new portfolio of PET yarns to its customers in the automotive industry.

Source: www.beaulieuyarns.com

Kimberly-Clark commemorates 150th anniversary with grants

As Kimberly-Clark celebrates 150 years of providing Better Care for a Better World, the Kimberly-Clark Foundation announced that it will honor this milestone anniversary by awarding three $150,000 grants to global nonprofit organizations that are working to improve the well-being of people around the world.

Since its inception in 1952, the Foundation has provided over $440 million in financial support to targeted causes that align with the company’s social impact goals.

Kimberly-Clark employees selected the grant recipients via online voting from a list of nonprofit organizations that focus their work on the priority areas of the company’s brands and the Kimberly-Clark Foundation. The awardees are:

• Water.org has positively transformed more than 45 million lives around the world with access to safe water or sanitation;

• She’s the First has worked with grassroots organizations to make sure girls everywhere are educated, respected and heard; and

• Project HOPE has provided nurses and midwives with the skills they need to save the lives of women and babies around the world.

Source: kimberly-clark.com

IMA North America appointed as IMA Teknoweb’s sales subsidiary for nonwovens

converting and packaging lines in the American Market

IMA Teknoweb, the global market leader in the nonwoven converting and packaging market, announced major changes in its US structure: the sale operations of its wet & dry wipes and face mask manufacturing and packaging solutions are now assigned to IMA North America Inc., an IMA Group subsidiary; active in the North American market since 1982.

IMA Teknoweb’s former dedicated branch in the region, Teknoweb North America, has been purchased by

HMSC LLC. The new company will be the exclusive supplier of IMA Teknoweb’s spare parts in the USA.

IMA North America, led by Stewart Harvey, has been present in the U.S. market for 40 years: IMA was

one of the first major European manufacturers of packaging equipment to establish their own operation in North America. Located in Leominster (MA), in a 100,000 Sq. Ft. building; it serves both as Sales and Service Provider for major IMA Group brands and as a manufacturer of counting machines and integrator of packaging lines. IMA North America employs over 100 people, which includes more than 10 Regional Sales Managers each with specific tech skills in their respective markets.

HMSC, located in Loganville (Atlanta) GA, includes engineering and technical staff as well as import

specialists who are committed both to maintaining the availability of spare parts for American customers,

enhancing IMA Teknoweb’s presence in the United States, and to ensuring optimal communication. HMSC

also offers contract design services as well as application and process improvement assistance.

Source: ima.it/en

New Director of Marketing for Perseus Group Manufacturing Division

Perseus Group, a Constellation Software company, announced that Natalie J. Flowers has joined its organization as Director of Marketing. By utilizing her skill set, she will align with Perseus Group’s four existing Manufacturing Execution Software (MES) companies. This incudes, MAJIQ Inc., POMS Corporation, Ediwise, and MOPSsys, as well as with future merged or acquired software manufacturing companies.

Flowers brings over 17 years of rich business expertise to the Perseus Group, with a career emphasis on sales, marketing, branding, and corporate account management. Her industry experience is diverse, having worked for a leading industrial MRO supplier, a technology-based engineering firm in the pulp and paper industry, a pharmaceutical manufacturer, and a Wall Street firm.

She joins the Perseus Group as the organization continues to focus on smart manufacturing software, offering domestic and international manufacturers integrative solutions for roll, sheet, and bale manufacturing in the pulp, paper, and nonwoven industries. Flowers will work with leadership teams to develop and execute strategic multi-channel marketing through active collaboration with internal and external stakeholders.

Perseus Group is a leader in enterprise software and services for the pulp, paper, and nonwoven industries.

Source: www.csisoftware.com

More than 450 professionals convene, connect at World of Wipes® International Conference

More than 450 participants from 18 countries made in-person connections and gained innovative insights into the segment’s future at the World of Wipes® (WOW) International Conference at the Marriott Marquis in Chicago.

INDA, the Association of the Nonwoven Fabrics Industry, reported strong attendance and activity at its 16th WOW conference, June 27-30. Highlights included a powerful conference, award presentations, a separate 1.5-day WIPES Academy training course, and a new mentorship program.

WOW speakers focused on the future of the $17 billion wipes sector amid changing consumer trends, supply chain complexities, sustainable packaging demands, and medical disinfection challenges. Program sessions included Circular and Sustainable Wipes, Supply Chain Challenges, Sustainable Substrates, Disinfection Concerns, Sustainable Packaging Trends, and Flushability Developments.

Tony Fragnito welcomed participants in his new role as INDA President for the first time since succeeding Dave Rousse, now President Emeritus and advisor.

“WOW is the nexus for wipes professionals to convene and connect,” said Fragnito. “With powerful content addressing the key issues facing the industry – sustainability, economics, and supply – the conference was highly valued by participants to advance their businesses and the industry.”

INDA announced that WOW 2023 will be held July 17-20, at the Atlanta Marriott Marquis in Atlanta, Georgia.

Source: www.worldofwipes.org

SWM, Neenah complete merger and form Mativ

Mativ Holdings, Inc. announced the successful completion of the merger of equals between Schweitzer-Mauduit International, Inc. (“SWM”) and Neenah, Inc., two leading global manufacturers of specialty materials, effective July 6, 2022.

Mativ has approximately $3 billion in sales, supporting customers in more than 100 countries, and manufacturing capabilities on four continents. Beginning Wednesday, July 6, 2022, the Company will commence trading on the New York Stock Exchange at the market open, under the new ticker symbol “MATV.”

Pursuant to the merger agreement, Neenah shareholders received 1.358 shares of SWM common stock for each share of Neenah common stock owned. SWM’s shareholders will continue to hold their shares of SWM common stock. All SWM shares are now shares of Mativ common stock.

Source: www.mativ.com

BASF and Permionics partner on face masks

BASF has joined hands with Vadodara-based membrane manufacturer, Permionics Membranes, to extend, for the first time, the application of BASF’s Ultrason E polyethersulphone (PESU) polymer into coated fabrics that serve as particulate and bacterial filter for face masks. The face masks using the fabric as a middle layer are highly breathable, washable and re-usable unlike conventional face masks. They are designed for usage in the Indian healthcare market. Permionics selected Ultrason E for its coated fabric, Perma Bioshield. The fabric is made by adhering an antimicrobial coating made of Ultrason E to the matrix of a non-woven fabric as a bonded support. Ultrason E is a high purity material with low gel and oligomer content that ensures a stable membrane manufacturing process. PESU can be used in a wide pH range (0-13) without deterioration. It is especially suitable for the production of durable hollow-fibre membranes and filters for use in the food, beverage, electronics and pharmaceutical industries.

Source: www.permionics.com

Milliken & Company enters outdoor fabric market

Global textile manufacturer Milliken & Company announced the launch of Milliken Outdoor Fabrics, the organization’s entrance into the outdoor performance fabrics market.

The new line, premiering at Casual Market Chicago in July, marks the first time the 155-year-old manufacturer has supplied the outdoor furniture fabric market.

The first collection from the outdoor line, on display in Chicago, is New Vistas, a line of performance fabrics designed to move effortlessly from indoors to outdoors. Including 10 patterns across 72 skus, New Vistas is a collection of 100 percent solution-dyed acrylic fabrics that feature a non-PFAS finish to make it stain and water resistant. These fabrics are in-stock and ready to ship from South Carolina. The new line includes a five-year limited warranty. A follow up collection, Outer Realm, is anticipated to launch in late 2022.

Source: outdoor.milliken.com

Global textile machinery deliveries higher than pre-pandemic

Global shipments of spinning, texturing, weaving, knitting, and finishing machines increased sharply in 2021 compared to the prior year. Deliveries of new short-staple spindles, open-end rotors, and long-staple spindles rose by +110%, +65%, and +44%, respectively. The number of shipped draw-texturing spindles surged by +177% and deliveries of shuttle-less looms grew by +32%. Shipments of large circular machines improved by +30% and shipped flat knitting machines registered a 109%-growth. The sum of all deliveries in the finishing segment also rose by +52% on average, according to the 44th annual International Textile Machinery Shipment Statistics (ITMSS) just released by the International Textile Manufacturers Federation (ITMF), Zurich/Switzerland.

The report covers six segments of textile machinery, spinning, draw-texturing, weaving, large circular knitting, flat knitting and finishing. The 2021 survey has been compiled in cooperation with more than 200 textile machinery manufacturers representing a comprehensive measure of world production.

Source: itmf.org