In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: March 24, 2023

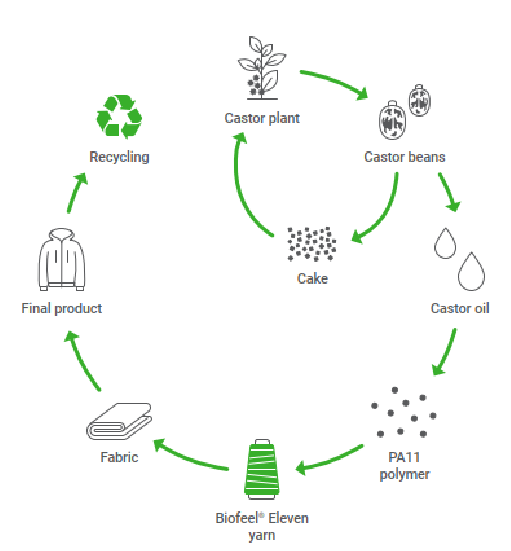

RadiciGroup Launches 100% Naturally Sourced Yarn

Biofeel® Eleven is a natural-sourced yarn born of a story that begins in India. In Hindi, “Eranda” is a small bean from which the perfect oil is extracted for the biopolymer from which everything begins. And it is castor oil that is the source of these new 100% sustainable yarns, which can be used for fabrics and fine garments in many sectors, from fashion to sports, from automotive to home textiles.

RadiciGroup, the only European producer of this material, has chosen the “Performance days” trade fair that took place in Munich in March to unveil this yarn with excellent technical and environmental performance.

Today, 80% of the world’s castor oil plantations are in India, particularly in the Gujarat region, due to its favorable climatic conditions. In this area, local people can earn an additional income by cultivating semi-arid land that does not compete with food production, and by applying the skills they have acquired over time to this work. Over the years, thanks to research, development and innovation in the value chain, the seeds from which the oil is produced have been selected and certified to ensure the finest quality, also in terms of end uses.

Castor beans contain around 45% oil, rich in ricinolein, from which the bio-polymer polyamide 11 is derived. This is the polymer RadiciGroup uses for its Biofeel® Eleven yarn. What remains after the first pressing is a highly effective bio-fertiliser that is returned to the soil. In short, a true example of circularity and “zero waste”.

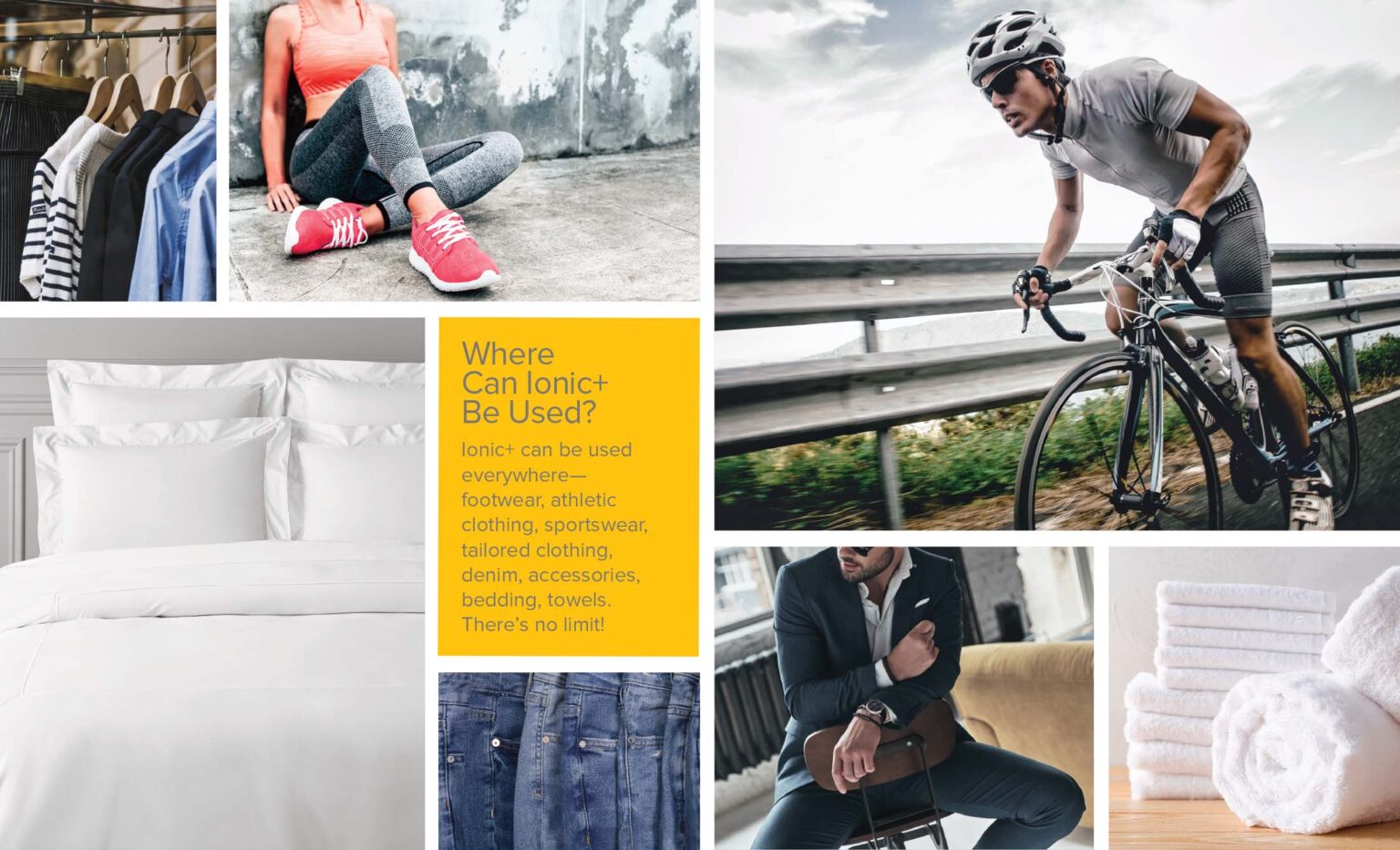

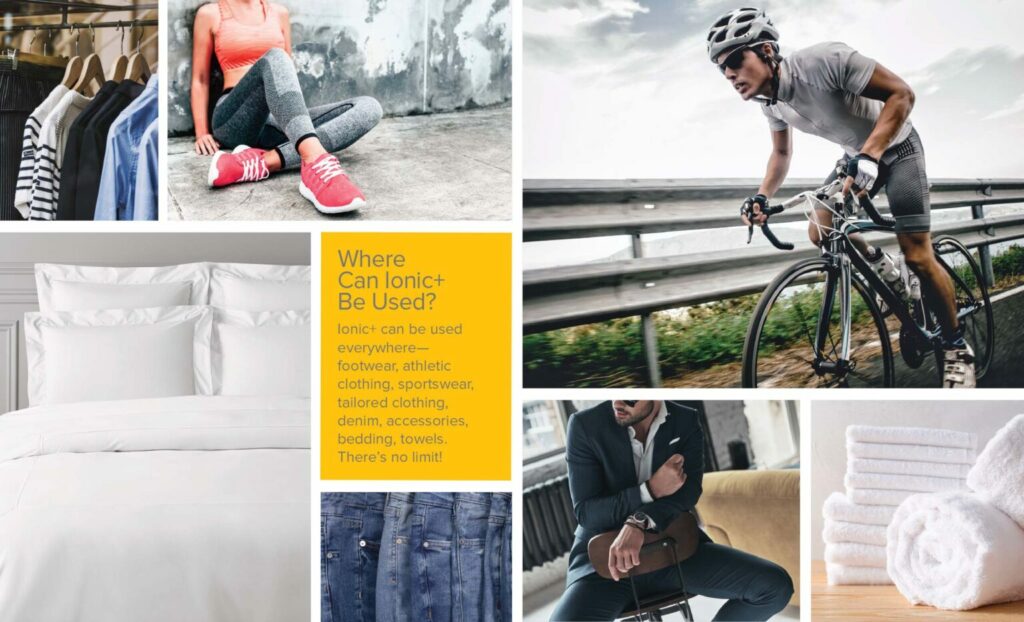

Noble Biomaterials’ Ionic+® Botanical Technology Receives EPA Registration

Noble Biomaterials, a global leader in antimicrobial solutions for soft surface applications, announced its latest antimicrobial technology has received official EPA registration.

Ionic+® Botanical uses a bio-based registered citric acid formula to inhibit the growth of microbes and reduce odor on fabric and other soft surfaces. Noble Biomaterials began development of the proprietary Ionic+® Botanical formula in 2021 and filed for EPA registration as part of the development process.

Registering the citric acid-based active formula allows Noble’s licensed partners to claim antimicrobial benefits such as “odor control” and surface protection for various performance fabric applications.

Citric Acid is one of the most commonly used ingredients in food and beverage products, pharmaceutical and dietary products, and cleaning agents. The registration of Noble’s citric formula introduces this commonly used product into a whole new arena – the protection of textiles and other everyday manufactured materials. Noble has seen the growing interest in plant-based solutions and recognizes that the Ionic+® Botanical technology can be an important step in meeting the demand for high performance, sustainable material preservation solutions.

Noble has a history of groundbreaking innovation, covering the first EPA-registered silver-based textiles, advances in the use of silver metallized yarns and fibers in wound care, to the first silver antimicrobial textile on the International Space Station. Noble’s antimicrobial products are found on elite athletes, in healthcare and medical supplies, as well as in military applications.

Jeanologia Reduces Water Consumption in Garment Manufacturing

Spanish company Jeanologia, a world leader in the developing eco-efficient technologies, has reduced water consumption from 100 to 1 liter from the fabric to the finished garment, thanks to its technologies.

For World Water Day, celebrated on March 22, Jeanologia pointed out that the textile industry is one of the most water-consuming, most wastewater-producing and one of the most polluting. For this reason, the company is highlighting the need to convert production centers into eco-efficient plants that promote sustainability and circular economy.

In comparison to conventional procedures, the company’s G2 Dynamic and Anubis technologies for textiles minimize water use by up to 95%, chemical consumption by 100%, energy consumption by 80%, and carbon footprint by up to 40%.

Without using water, chemicals, or pumice, the ground-breaking G2 Ozone air-washing machine gives jeans a vintage look and stone-washed effects. Moreover, its eFlow technology employs nanobubbles rather than water to deliver chemicals to the garment, enabling zero discharge and reduced water usage. Using these technologies together, Jeanologia reduces the amount of water and chemicals used in the process by 80% and 70%, respectively.

The H2Zero, a tiny water treatment system that links to each washing machine to create a closed circuit, is essential for cutting water consumption to just 1 liter per wash.

Glen Raven to Eliminate PFAS Across Portfolio

As part of its longstanding commitment to continuing a pattern of transparency, sustainable practices and providing the highest quality products, Glen Raven Inc. today announced it has begun to phase out PFAS chemicals across its global fabric portfolio.

The company began incorporating optimal non-PFAS solutions into production last month and all production will be transitioned to non-PFAS by the end of 2023. In addition, all new fabric designs, including for the company’s flagship Sunbrella® brand, will be specified as non-PFAS and will be produced using the company’s new non-PFAS solution.

Cone Denim Establishes a Certified Supply Chain for Recycled Cotton in Mexico

Cone Denim® has established a certified supply chain for recycled cotton in Mexico. The company’s Recycled Claim Standard (RCS) certification now includes a closed-loop process for recycled cotton, providing customers with verification and documentation of recycled cotton used in the manufacturing of Cone Denim fabrics in the Western Hemisphere.

“While both of our mills in Mexico are already RCS certified for fabrics, we went a step further in having our fiber supplier certified,” said Cone Denim President Steve Maggard.

Cone Denim identified and engaged with a third-party supplier in Mexico to certify their process for recycled cotton. The supplier was required to meet the certification standards established by Textile Exchange and certified by Control Union. Cone Denim received RCS certification with this new process in March and will undergo a yearly audit to maintain its standing.

Trützschler Marks 75 Years in Mönchengladbach

It’s time to celebrate for Trützschler: 75 years ago, the family business founded its headquarters in Mönchengladbach-Odenkirchen, Germany.

Now, it looks back on a long tradition of training young people. The site in Mönchengladbach is officially three-quarters of a century old – and is still a dynamic place to work. To keep it that way, Trützschler is looking for motivated young employees.

Trützschler is what one might call a hidden champion. Experts from the textile sector know the company as the world’s market leader for spinning preparation. However, people outside this industry are often unaware of what happens behind the walls of the headquarters in Mönchengladbach. And those people include school and university students, as well as young professionals.

Trützschler textile machines don’t make jeans or T-shirts. Instead, they play a key role at the beginning of the textile value chain. Their goal is to clean, blend and structure raw materials like cotton to make a uniform sliver that is then spun to create a yarn.

The company’s main customers include spinning mills from all over the world who use Trützschler technologies in a wide range of different applications. Trützschler supports its customers with recycling textiles and producing sustainable yarns from production waste or old textiles. The company also provides its customers with advantages when it comes to digitalization, which plays a central role in global markets. Examples include intelligent and self-optimizing machines, as well as digital platforms for optimizing processes and saving resources.

MEZGER, INC. Becomes Official Distributor for Reiners & Fürst

MEZGER, INC. announced that they are now the official distributor for Reiners + Fűrst rings and travellers in North America.

Around the world, the brand Reiners + Fürst stands for spinning rings and ring travellers that meet the highest quality requirements with a top price-performance ratio. Customers worldwide repeatedly confirm that R+F is their leading supplier of rings and ring travellers of the highest quality.

R+F is a family-owned German company, now in its third generation. This allows them to plan for the long-term while enabling them to make important decisions in the short term. Nearly 100 experienced employees meticulously take care of the production and marketing of a very broad range of spinning rings and ring travellers.

Celliant with Repreve Earns Prestigious Recognition

Materials science company Hologenix announced that CELLIANT® with REPREVE®, a performance fiber made from recycled materials and enhanced with IR technology, has been shortlisted in the Drapers Sustainable Fashion 2023 Awards.

Introduced with global textile solutions provider UNIFI® makers of REPREVE®, CELLIANT with REPREVE is honored in the Sustainable Textile Innovation Category of the awards. The Drapers Awards recognize the strides that are being made in reducing the industry’s environmental impact and creating fairer working conditions across the supply chain. Drapers, which is a leading authority on fashion retailing since 1887, said the quality and quantity of entries were higher than ever this year. Judging was underpinned by the UN-backed Sustainable Development Goals. Winners will be announced at a ceremony on May 25 at The Brewery in London.

This recognition is the second award for CELLIANT with REPREVE since its launch in the fall of 2022. Previously it was named a Selection in the Fibers & Insulation Category of ISPO Textrends Fall/Winter 2024/25. This is also the second year in a row that a Hologenix innovation has been shortlisted in the Drapers Sustainable Fashion Awards.

Purecare Launches Premium Celliant Viscose Bedding

Purecare, the wellness-focused bedding essentials manufacturer and category leader, has launched sheets and pillowcases with CELLIANT® Viscose, the first time the fiber has used been in luxury bedding products in a new offering aptly named the “Recovery Collection.” CELLIANT Viscose, which converts body heat into infrared energy, promotes local circulation and helps regulate body temperature so you sleep more comfortably and wake up refreshed and rejuvenated. It is also a unique combination of nature and performance, as the CELLIANT bio-responsive minerals are embedded into plant-based fibers.

Developed by materials science innovator Hologenix®, creators of CELLIANT, and Kelheim Fibres, the leading manufacturer of viscose specialty fibers, CELLIANT Viscose is the first in-fiber sustainable infrared viscose. This sustainable solution provides all the benefits of being a viscose fiber – lightweight, soft, highly breathable, excellent moisture management — as well as the fiber enhancements from CELLIANT infrared technology. CELLIANT has been clinically demonstrated to promote faster recovery and restful sleep, as it improves local circulation and cell oxygenation, enhancing thermoregulation and comfort.

Offered at retailers across the nation and online, the collection is available in five popular colors: dove gray, ivory, clay, moss, and sage in Queen through Split California King sizing and Queen and King pillowcases. The Precision-Fit® corners on the fitted sheets have a one-inch elastic cuff to ensure that they stay securely on the bed. The sheets are also compatible with adjustable base mattresses. The Recovery Collection sheets and pillowcases are also treated with Antimicrobial Silver Product Protection (AgCI).

Program Announced for World of Wipes

INDA has announced the program for the World of Wipes (WOW) International Conference, July 17-20, Atlanta, Georgia. Key topics include: Plastics policy: closing the ‘intention-action’ gap, sustainable manufacturing practices, what consumers think about sustainability and how they are driving cultural change, supply chain transparency, wipes advancements, flushability developments, and a special CEO panel sharing their organizations’ approach to inflation, supply chain challenges, and capacity/demand balance.

Among the leading organizations presenting at this year’s event are: Berry Global, Birla Cellulose, Bringabouts, Bureau Veritas, Diamond Wipes, Freudenberg Performance Materials, Glatfelter, Goodwipes, Kimberly-Clark Corporation, National Cotton Council, Mango Consulting, Plastics Industry Association, Rockline Industries, Sharon Laboratories, and Trützschler Nonwovens. Program and speaker details are available on the WOW website.

Two new features at WOW this year are Lightning Talks and Lunch Around. Lightning Talks are an opportunity for tabletop exhibitors to highlight their innovations in “supersized elevator speeches” to WOW participants. Lightning Talks will take place before the tabletop exhibits open Tuesday and Wednesday evenings. The Lunch Around opportunity connects participants and thought leaders from the wipes industry at select downtown Atlanta restaurants on Tuesday and Wednesday. Space is limited and is first-come, first-served.

WOW kicks off with the Wipes Academy, a comprehensive course including elements of market research, materials, chemistry, converting, and regulatory filing. This course has been redeveloped to include all aspects of wipes development from concept to commercialization.

The Wipes Academy is led by Heidi Beatty, chief executive officer, and Paul Davies, Ph.D., Consultant, Crown Abbey LLC. Ms. Beatty and Mr. Davies bring decades of practical experience to give participants real-world solutions for product development challenges and tools to improve processes.

Registrations and tabletop exhibit reservations are open with early registration discounts offered until June 5. Nominations will be accepted for the World of Wipes Innovation Award until May 5, 2023. For more information or to nominate, visit: www.worldofwipes.org/award-nominations.html

INDA welcomes six new board members

INDA, the Association of the Nonwoven Fabrics Industry, has welcomed six new members to its 2023 Board of Directors. The Board of Directors are responsible for contributing to INDA’s strategic focus in support of the industry. They inform INDA’s policies and programs to ensure we meet the needs of our more than 360 corporate members.

“I am pleased to welcome these industry leaders who bring a diverse set of skills, experience and insights to INDA,” said Tony Fragnito, INDA President. “We look forward to advancing INDA’s reputation as the ‘go to’ source for industry, technical, workforce development and market intelligence in the engineered materials industry.”

The new board members are:

Ricardo Fasolo, Managing Vice President, Fitesa Inc – Ricardo Fasolo is Managing Vice President for Fitesa in North America.

Neil Johnson, President, AstenJohnson – Neil Johnson is President of AJ Nonwovens, a division of AstenJohnson Holdings, a multinational private technical textiles company.

Chris Roeder, Director – Strategy, Marketing & Innovation, Global Cellulose Fibers, International Paper – Chris Roeder joined International Paper (IP) in 1996 in Kansas City, MO, as an engineer for IP’s Consumer Packaging business.

Paul E. Rollin, Jr., Ph.D., Senior Principal – Global Hygiene, ExxonMobil Product Solutions Company – Paul Rollin earned his B.S. in Chemistry from Morehouse College in Atlanta, Georgia and his Ph.D. in Polymer Science from The University of Akron in Akron, Ohio.

Jodi Russell, Vice President R&D, Cleaning Innovation, Packaging & Sustainability, The Clorox Company – Jodi Russell has spent 25 years leading global innovation across multiple categories in the consumer-packaged goods industry.

Julie Schertell, President and Chief Executive Officer, Mativ – Julie Schertell is Mativ’s President and Chief Executive Officer and serves on its Board of Directors.

INDA’s Board of Directors

The Board is comprised of elected Board Officers. One-third of the entire Board is elected each year for a three-year term by a majority vote of INDA’s general membership. INDA’s Executive Committee, empowered to act on behalf of the Board between meetings, consists of the Board Officers plus four appointees.

The Executive Committee includes these officers and appointees: Bryan Haynes, Senior Technical Director for Global Nonwovens, Kimberly-Clark Corporation – Chair; Richard Altice, President & Chief Executive Officer, NatureWorks – Vice Chair of Planning; Barbara Lawless, VP of Sales and Marketing – Medical Products, Precision Fabrics Group, Inc. – Vice Chair of Finance; Paul Latten, Director of Research & Development & New Business, Southeast Nonwovens, Inc. – Appointee; Robert Weilminster, EVP & General Manager, US & Canada – Health, Hygiene and Specialties Division, Berry Global – Appointee; and Tom Zaiser, CEO, FiberVisions – Appointee.

Technical Textiles for Health and Environment

The manufacturing sector is gaining attention worldwide due to the recent economic situation and supply chain issues.

Recently, United States, United Kingdom and Australia formed the AUKUS nuclear submarine partnership, which will boost jobs as well S&T (science and technology) partnerships in the pacific region. India’s Air India’s proposed procurement of Boeing and Airbus planes will create manufacturing and R & D jobs in the United States and France. These are some examples of the revival in manufacturing in developed nations. All these projects involve some form of advanced textiles such as soft composites, PPEs, etc.

The technical textiles sector globally has an annual growth rate of above 5 percent. On February 26, 2023, the usefulness of advanced textiles in enhancing human lives, saving the environment, and creating jobs was presented to a global audience at the recently concluded World Textile Conference-3 organized by the world’s largest professional association in the field of textiles, Textile Association (India) [TAI].

The talk featured the demonstration of a cotton-based oil absorbent and emphasized the importance of developing value-added textiles to enhance human life and protect the environment. Seshadri Ramkumar, Professor, Texas Tech university, pitched the concept developed by U.S. Department of Defense that involves 4S for the growth of the industry: Sensing; Shaping; Sustaining and Shielding (Growing). The sector can sense the need of technologies and products, map the requirements, build, and grow. There is a need to involve more sustainable products and processes to combat global warming.

There is more work to do in the technical textiles sector to develop technologies and products in a cost-effective way to include sustainable aspects. Developing economies need marketing help in this sector.

In the audience were Tony Fragnito, President of USA-based INDA, Dr. Bryan Haynes, Chairman of the Board of INDA-USA. Dr. P R. Roy, former Group CEO of Arvind Group, Dr. Jaywant Irkhede, Department of Trade and Industry, Republic of South Africa, the office bearers of Textile Association (India) and many other participants representing all walks of the textile industry from fiber to fashion.

The conference attracted over 800 participants who were from India, USA, Germany, Switzerland, South Africa and Uganda.

Professor Seshadri Ramkumar’s talk can be found below: