In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: November 26, 2021

BASF announces ‘Net Zero Accelerator’ project to boost CO2 reduction plan

With a new project organization, BASF is bundling and accelerating its extensive cross-company activities to reduce its CO2 emissions by 25 percent by 2030 compared with 2018 and become climate neutral by 2050. The unit, called “Net Zero Accelerator”, focuses on implementing and accelerating projects relating to low-CO2 production technologies, circular economy and renewable energies. “With the new project organization, we are continuing to accelerate and create more powerful structures within BASF to achieve our ambitious goals,” said Dr. Martin Brudermüller, Chairman of the Board of Executive Directors of BASF SE. “This further step demonstrates the determination to drive forward our transformation to a climate-neutral company.”

The Net Zero Accelerator unit will be led by Dr. Lars Kissau (48) as President, reporting directly to the Chairman of the Board of Executive Directors. Under Kissau’s leadership, existing and new projects to achieve the CO2 reduction targets will be launched and driven forward at corporate level worldwide in the future. The aim is to move the projects into the implementation phase over the next few years. By pooling expertise around renewable energies, alternative raw materials and CO2 reduction technologies, BASF will increase the speed of implementation and achieve scaling effects more quickly, thus making an important contribution to climate protection. In parallel, the operating divisions will continue to work on divisional projects to implement BASF’s ambitious CO2 reduction targets.

Ongoing cross-company projects managed by the new unit include BASF’s activities in the field of circular economy such as ChemCycling or CO2-free technologies such as methane pyrolysis. Renewable energies are another field of activity. BASF has initiated various projects in this area and signed specific agreements in recent months. Examples include a contract with Vattenfall to acquire a 49.5 percent stake in the Hollandse Kust Zuid wind farm with a total capacity of 1.5 gigawatts and a 25-year electricity supply contract to purchase 186 megawatts of capacity from Ørsted’s planned Borkum Riffgrund 3 offshore wind farm in the German North Sea.

The new project organization, based in Ludwigshafen, Germany, will start on January 1, 2022, initially with around 80 employees.

Source: basf.com

Hygienix attracts nearly 400 absorbent hygiene industry professionals as the event returns to live format in Scottsdale, Arizona

Hygienix – a leading event for the absorbent hygiene & personal care markets – drew 390 global industry professionals for in-person conference sessions, workshops, award presentations and tabletop receptions, Nov. 15-18, in Scottsdale, Arizona.

Among the event highlights were the presentation of the 2021 Hygienix Innovation Award to Kudos, the first 100% cotton disposable diaper, and the INDA Lifetime Service Award to Nick Santoleri, chief operating officer of Rockline Industries.

In its return as a live event after the Hygienix was forced to be presented virtually in 2020 due to the pandemic, participants from 17 countries enjoyed meeting face-to-face at The Westin Kierland in Scottsdale, Arizona, over three days of presentations at the conference and networking at the welcome and tabletop display receptions.

The Hygienix conference featured 28 speakers on topics including New Options for a Responsible End-of-Life; Product and Process Innovation in Absorbent Hygiene Products (AHPs); Haptics: Four Approaches to Assessing Feel, and E-Hygiene Advancements; Absorbent Hygiene Products Market Stats, Trends and Policy Insights; Feminine Care: Challenges to the Status Quo; and New Approaches and Unmet Needs in Baby and Incontinence AHPs.

Source: hygienix.org

Indorama Ventures included in the DJSI for the fifth consecutive year

Indorama Ventures Public Company Limited (IVL) is included in the Dow Jones Sustainability World Index (DJSI World) and the Dow Jones Sustainability Emerging Markets Index (DJSI Emerging Markets) for the third and fifth consecutive years respectively.

“As a global leader, this is an important milestone in our operations as we transform the chemical industry,” said Yash Lohia, chief sustainability officer at IVL. “Our inclusion in the DJSI for the fifth year running is a tribute to how IVL’s operations are contributing to a more sustainable future. Our strategy includes focusing on climate action, aligning with the world’s net zero ambitions, strengthening the circular economy and PET recycling with our ambitious targets, and enhancing shared value with our stakeholders.”

This year, 139 chemical companies were selected from over 11,000 companies from 61 industries and about 5,300 companies eligible for S&P Global ESG indices. IVL ranked in the 97th percentile with full scores in the areas of environmental and social compliance, enabling policies through industry associations, human rights protections in the workplace and value chain and sustainable water management including forecasting potential water-related risks in operations.

“We congratulate Indorama Ventures for being included in the DJSI for DJSI World and DJSI Emerging Markets,” said global head of ESG Research at S&P Global Manjit Jus. “A DJSI distinction is a reflection of being a sustainability leader in your industry. The record number of companies participating in the 2021 S&P Global Corporate Sustainability Assessment is testament to the growing movement for ESG disclosure and transparency.”

Source: indoramaventures.com

Toray subsidiary Zoltek boosts large-tow carbon fiber production

Toray Industries, Inc., announced that its U.S. subsidiary Zoltek Companies, Inc., will bolster large-tow carbon fiber (with more than 40,000 filaments) production capacity in 2023. The upgrade will cost around USD$130 million (around ¥14 billion). A Zoltek facility in Jalisco, Mexico, will lift its annual capacity around 54%, to more than 20,000 tons, boosting the combined annual capacity of that company’s Mexican and Hungarian operations to about 35,000 metric tons.

Toray expects the market for this fiber to expand over the medium through long terms. That is because of growing deployments of wind power as an eco-friendly source of renewable energy. An associated factor is rising demand for longer and lighter blades to boost generating efficiency, fueling the use of carbon fiber, which is lightweight, strong and rigid. The capacity increase will stabilize supplies to cater to expanding large tow carbon fiber demand. Zoltek will keep drawing on production facilities in the United States, Hungary, and Mexico to take advantage of increasing global demand, particularly for wind turbine blades.

Toray has made expanding globally in promising areas a central strategy under Project AP-G2022, its medium-term management program. The company is accordingly pursuing growth in energy applications for the carbon fiber composites. Toray will fully leverage its comprehensive capabilities in keeping with its corporate philosophy of contributing to society and help materialize a carbon-neutral economy by 2050.

Source: toray.com

Kudos diaper technology wins Hygienix Innovation Award

Amrita Saigal, founder and CEO of Kudos, a provider of baby diapers and wipes based on natural, plant-based materials, accepted the 2021 Hygienix Innovation Award for her company’s diaper technology. The Kudos diapers are designed to provide a leak-free, natural options for babies.

Kudos technology protects against leaks and blowouts using sustainable, plant-based materials that are naturally kind to diaper rash-prone skin. Kudos are also the only disposable diapers to have earned the cotton natural seal for being lined with 100% clean cotton, rather than the plastic materials employed by most disposable diapers on the market today.

The Hygienix Innovation Award recognizes and rewards innovation within the entire disposable absorbent hygiene value chain that utilizes nonwoven fabric or technology in a way that expands the usage of nonwovens. Presented annually at the Hygienix conference eligible categories include, but are not limited to: raw materials, roll goods, converting, packaging, active ingredients, binders, additives and end-use products.

The Technical Advisory Board (TAB) of INDA, Association of the Nonwoven Fabrics Industry, which organizes the Hygienix conference, chooses Hygienix Innovation Award finalists that, in their view, exemplify innovation within the absorbent hygiene value chain and advance the use of nonwovens. Finalists present their innovation to the industry at the Hygienix conference. Voting is weighted equally across three voting bodies: (1) INDA’s Technical Advisory Board (TAB); (2) the Hygienix Conference Committee; and (3) the respective registered Conference attendees.

Source: hygienix.org

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Rockline’s Santoleri earns INDA ‘Lifetime Service Award’

Nick Santoleri, chief operating officer for Rockline Industries, was honored with the “Lifetime Service Award” by INDA, the North American association for the nonwovens industry. The award was presented to Santoleri at INDA’s Hygienix conference for the absorbent hygiene industry, Nov. 15-18, in Scottsdale, Arizona, recognizing his long-established record of service to INDA, specifically, and the nonwovens industry as a whole. Requirements for the award include 20 years of service in nonwoven-related functions and standing as a current of retired INDA member in good standing with a strong record of participation in INDA activities.

Santoleri has been with Rockline, a global private branded supplier of coffee filters, baby, personal care and household wet wipe products, since 1999 and became COO in 2020. Prior to that, he spent 20 years with Kimberly-Clark Corporation, in various engineering, product and manufacturing roles, spanning product lines from consumer tissue and towels to baby wipes.

Santoleri earned his engineering degree from Drexel University, with additional education at University of Virginia’s Darden School of Business, Supply Chain Management studies at Cranfield University in the UK, Northwestern’s Kellogg School of Business in Chicago, and Harvard Business School in Cambridge, Mass.

Santoleri has served as a board and executive board member at INDA and has participated and/or chaired many of the industry conferences, including WOW, Vision, and GoWipes Europe.

For a full background on Santoleri’s career, see: https://www.inda.org/about-inda/inda-hall-of-fame/entries/nick-santoleri/.

Source: inda.org

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Uster Technologies announces CEO succession plan

Uster Technologies announced a succession plan for its chief executive officer with a transition to be completed by April 2022. At his own request, current CEO Thomas Nasiou decided to step-down, and will be succeeded by Davide Maccabruni, former CEO of SSM Schärer Schweiter Mettler AG and General Manager of Savio Group Components.

Thomas Nasiou, who has been CEO of Uster for the past six years having served 16 total years with the company, has decided to step-down as CEO. “Since I joined Uster and also during my tenure as CEO, I only felt privileged and honored to meet and work with so many colleagues and friends,” said Nasiou. “We have been through some exciting and challenging times, innovating, developing and growing together, keeping in mind creating value for ourselves, for our organization and for our customers and partners. We maintained our focus on the needs of our customers and our commitment to providing the best solutions to help them with the many challenges they face in todays but mainly tomorrow’s demanding market environment. The work has been enjoyable and fulfilling. It is time for me to change my priorities in life and focus more on other personal interests, which require time and energy. I am glad that we have found the ideal successor, so we can work towards a seamless transition for the future.”

Nasiou’s successor, Maccabruni, will join Uster on January 1, 2022 and will take over as CEO on April 1, 2022. Maccabruni has extensive experience in the textile industry. His experience has been gained working in both innovation and management roles at Sultex (ITEMA weaving), at SSM and at Savio.

Source: uster.com

Early-bird registration opens for Techtextil North America and Texprocess Americas 2022

Techtextil North America and Texprocess Americas will return to the Georgia World Congress Center in Atlanta, Georgia May 17-19, 2022. Early-bird registration is now open for this event until Friday, February 18, 2022.

The co-located events will bring decision makers from all of the major industries that touch technical textiles, nonwovens, sewn products, equipment and technology together in one place to experience the latest innovations. With a single badge, visitors gain access to both show floors, including 500+ exhibiting companies, international media outlets and pavilions representing top contributors to the global textile industry.

Running concurrently with the show floor, the Techtextil North America and Texprocess Americas Symposia will each feature expert-led sessions on pivotal advancements, research and technology for the textile, nonwovens, and sewn products industries. One, two, and three day passes to each show’s symposium can be purchased through online registration.

Visitors are encouraged to register in advance not only for financial savings but to ensure a seat in the Symposia. The Official Techtextil North America & Texprocess Americas Reception will take place on the second evening of the show, May 18, 2022, and it also has a capacity limit, so all parties are encouraged to purchase tickets in advance.

Early-bird registration is available here.

Source: techtextil-north-america.us.messefrankfurt.com/

Steve Post joins Leistritz Extrusion as a product manager

Steve Post has joined Leistritz Extrusion as a product manager for Life Science and Specialty Film applications. Post began his career as a process engineer for Honeywell’s film business, and then transitioned into the extrusion machinery market, holding several positions over 20+ years at Davis-Standard. Most recently, Post was business development manager for Thermo Fisher’s Extrusion and Rheology business.

Over the course of his career, he authored more than thirty papers for TAPPI, SPI, AMI and other organizations. Post holds a bachelor’s degree in Chemical Engineering from the Pennsylvania State University.

Kelheim Fibres ranks among top viscose fiber producers in Canopy’s 2021 Hot Button Ranking for sustainability

Kelheim Fibres announced it has achieved a top ranking in the Canopy 2021 Hot Button Ranking, with an increase of 2.5 points over the prior year, putting it into a tie for third place out of 40 (approx.) viscose fiber manufacturers worldwide. This earns Kelheim a dark green/green shirt for the second year running. The Hot Button Report showcases viscose fiber manufacturers who have made commitments for responsible raw material sourcing, as well as overall sustainability.

Especially in the areas of transparency and procurement, the NGO Canopy, which is committed to the preservation of ancient and endangered forests, awarded Kelheim Fibres top points. Kelheim Fibres is the only viscose fiber manufacturer to achieve the European Commission’s EMAS (Eco-Management and Audit Scheme) certification, and it also publishes all environmentally relevant data publicly.

Kelheim Fibres also gained points in the area of “Next Generation Solutions” due to its use of alternative raw materials in fiber production. Together with the Swedish textile recycling company, Renewcell, Kelheim is pursuing large-scale production of high-quality viscose fibers from up to 10,000 tonnes of the 100% textile recyclate, Circulose, per year.

“As a manufacturing company, we take our responsibility towards the environment very seriously,” said Matthew North, commercial director at Kelheim Fibres. “Sustainable action must begin with the raw materials on which our products are based: Trees, and in particular the ancient and endangered forests of our planet, play an important role in climate protection as carbon reservoirs, as well as for biodiversity and many other ecological processes. It is our duty to protect this valuable and irreplaceable resource. We are very proud of our position in the Hot Button Ranking and will expand our pioneering role even further in the future.”

Source: kelheim-fibres.com

Teaching an old fiber new tricks

The extra-long staple Egyptian Giza cotton for years has been the fiber of choice for making premium clothing and home textiles. Recently, Egypt-based spinning specialist Mediterranean Textile Company (MTC) has been reinventing Giza cotton and teaching this old fiber new tricks to expand its market possibilities, competitiveness, and relevance to emerging market trends.

MTC is to launch a new line of Inherently flame-retardant (FR) spun yarns based on extra-long staple Egyptian Giza cotton blend, which is also known as Giza-Protect. This new line has been developed to offer customers excellent flame-retardancy and heat resistance with the natural softness and comfort of Egyptian cotton with no deterioration in flame retardancy after repeated washing or normal use over time. Making it suitable for multiple applications in protective clothing and industrial workwear.

Most significantly, notes the company the environmental credentials of this line of inherent FR yarns are enhanced through the use of natural fiber such as cotton, which is responsibly grown and processed.

“The global demand for fine cotton yarns has not seen much growth over the past years, and we saw an excellent opportunity to diversify our offerings and introduce Giza cotton to new emerging markets such as FR fabrics for protective clothing. The fineness and strength of Egyptian cotton provides higher durability and extreme comfort that cannot be achieved by any other cotton variety,” said MTC Managing Director Harald Westphal.

Giza-Protect is the product of an extensive R&D program that was conducted in partnership between MTC and Egypt-based textile research company Intexive. The R&D program was focused on developing a cotton blend yarn that possesses permanent FR functionality and has the ability to self-extinguish when the flame source is removed. This new yarn does not even melt or form droplets, and it is said to be blended with antistatic fiber which provides a double static control mechanism which protects workers against arc flash which has become the newest challenge to protective clothing.

“We have been working on this project for the past 2 years, and now we are ready to launch this new yarn. We have done stringent testing of woven fabrics from Giza-Protect yarns at The Textile Industry Research Association (AITEX) in Spain, and the yarn satisfies numerous FR standards around the world for technical fabrics for protective clothing, including EN 11612, EN 11611, EN 1149 and EN 64182,” said Intexive Managing Partner Dr. Mohamad Midani.

“Giza-Protect is an excellent example of the endless possibilities of Egyptian Giza Cotton, it’s a live demonstration on how this amazing fiber can continuously adapt to new market needs and trends. We see it as an opportunity to expand the reach of Egyptian cotton in new avenues that were never explored in the past!” said Westphal.

This new yarn is one example of the future range of MTC yarns, which is put forward to demonstrate the versatility of Egyptian Giza cotton. The yarn will be available for commercial supply starting 1st of January 2022, and it is said to be available in regular ring spun, compact and core spun yarn, in various blends of antistatic fiber ratio, in a wide range of counts Ne 5 – 100.

Additional facts about Giza-Protect:

- Giza-Protect is made with a rich blend of extra-long staple (ELS) Egyptian Cotton up to 50% by weight, the other 50% is made of manmade fibers details of which are proprietary. The fiber blend itself is naturally flame-retardant and doesn’t require topical FR treatments. In other words, it is the mix that makes the yarn inherently FR.

- ELS Giza cotton is entirely grown in specific region in northern Egypt also know as the Delta, and it’s being spun by the Mediterranean Textile Company (MTC) and other local spinners after collection and ginning. MTC is Egypt’s largest producer and exporter of fine Egyptian cotton yarns.

- Egypt in 2020 has joined the Better Cotton Initiative (BCI) in collaboration with UNIDO. Approximately 2,000 small-holder cotton farmers received training and support on how to grow Egyptian Cotton more sustainably while also improving their livelihoods.

- The fact that this yarn is inherently FR means that it has permanent flame-retardant functionality that doesn’t wash away or deteriorate with repeated washing, which is a great deal especially for workwear which is expected to provide protection over long use life with repeated washing. The main inherent FR alternative in the market is meta-aramid with brand names such as Nomex by Dupont and Teijinconex by Teijin, but the fact that meta-aramid is fully synthetic makes it uncomfortable to wearers. Giza-Protect is 50% Egyptian cotton, which is extremely comfortable, and it can even be used as a skin layer, apart from being way less expensive than meta-aramids. Another important point is that Egyptian cotton does not only has the longest and finest micronaire, but also the highest strength among any other cotton variety. This is why such yarn can not be made of any other type of cotton except the Egyptian ELS to fulfill the tensile strength requirements of workwear in EN ISO 11611 and 11612.

- The yarn can be easily dyed to a wide range of shades including high visibility colors. It’s dyed with cationic and reactive dyeing, which provide vibrant shades and excellent fastness.

- One of the development constraints from the early conception stages was to develop a yarn that is based on Egyptian cotton (this is MTC company specialty), so the challenge was how can we reinvent this traditional old luxurious fiber in modern functional applications and teach it new tricks. We have designed a rigorous experiment and defined very specific performance parameters and started optimizing our blend and through a long iterative process of prototyping-testing-refinement.

- Intexive is a textile research company; we work on different levels. On one level we do our own R&D and product developments such s PalmFil; on another level we do external R&D to our clients through a service agreement such as in case of Giza-Protect. In the Giza-Protect project MTC is the client and they have full ownership of this new yarn and were providing the R&D services.

- Over the past year we have been actively promoting PalmFil innovation and trying to attract sponsors to support scaling-up of this technology, and we are currently closing an agreement with a UK-based company, which will sponsor building a pilot plant in Egypt which should start operation in June 2022.

Source: mediterranean-textile.com & intexive.com

Virtual edition of Aachen-Dresden-Denkendorf International Textile Conference draws a crowd

The Aachen-Dresden-Denkendorf International Textile Conference was held in Stuttgart on November 9 and 10. The German Institutes of Textile and Fiber Research Denkendorf (DITF) organized a digital event this year after the conference in 2020 was cancelled due to the COVID-19 pandemic. All told, 360 participants from 25 countries and four continents took the opportunity to be present at this important European technical congress.

The conference is organized annually in alternation by the institutes ITM Dresden, DWI Aachen and DITF Denkendorf. More than 60 lectures in plenary sessions and three parallel sessions were on the program. Experts from industry and research reported on research results and marketable textile innovations in the fields of high-performance fibers, fiber composites, medical textiles, functionalization and textile machine construction. The topics of the conference focused on the upheavals that the textile industry has to cope with due to the digital transformation and the requirements of a sustainable circular economy.

The possibilities for textile applications are vast. Whether mobility with fiber composites, architecture with modern building materials or smart textiles for everyday work, health or for new extraordinary sports – there is hardly any area of life where high-tech textiles do not contribute to solving future challenges. The session “quo vadis textile machine concepts” showed that there is also still a lot of innovation potential in terms of methods and processes, which is being exploited.

Under the motto “From idea to practice”, the Forschungskuratorium Textil e. V. presented successful cooperation projects from the IGF-ZIM program in a separate transfer session, in which representatives from science and industry jointly developed and successfully implemented products and processes.

Speakers from this year’s partner countries Portugal and Spain gave a comprehensive insight into the textile industry and research of both countries with lectures and discussion contributions.

The conference program was complemented by a virtual exhibition of companies and institutes as well as more than 100 scientific posters. Three of the poster presentations were awarded the Best Poster Award of the Aachen-Dresden-Denkendorf International Textile Conference 2021.

Source: ditf.de

The doyen of silk testing

Silk would not normally spring to mind in relation to a company known worldwide for quality management in traditional yarn spinning – but there is a chapter on silk in the Uster story which certainly deserves to be highlighted. It’s about a man who was dedicated to silk and its use as a delicate fiber for the finest yarns and amazing fabrics. This look into an interesting history is presented to honor the life and work of a true silk expert.

The year 1948 was a major milestone for Uster Technologies, as the first yarn evenness tester was introduced to the market. Peter Haettenschwiler was an assistant involved in the development of the tester and then in showing the diagrams and test results to spinners. Actually, he brought quality management to the mills, where the diagrams were seen as aids to accurate pricing, improved quality and forecasting how the yarns would suit processing stages. In this role, he became Uster’s first textile technologist.

Haettenschwiler also had a very special hobby. He collected bagworm moths and butterflies. His knowledge and dedication allowed him to assemble the world’s largest collection of moths of the family known as bagworm moths, today housed in the Entomological Collection of ETH Zurich, Switzerland. He became a recognized expert on this species, and first identified and named over 30 new varieties not previously recorded. He also edited numerous specialist literature, enhancing his name and reputation among international experts in the field of Lepidoptera.

Silk testing progress

Silk is often praised as “the queen of all textile fibers” and a natural wonder. It’s no surprise therefore, that the quality parameters of spun silk fibers were of interest. Haettenschwiler tested silk spun yarn, but it must be said that it was some years along in the manufacturing of raw and spun silk until the first trials were made with commercially available testing systems. In the course of this work, cooperation with experts from silk institutes in Switzerland, Italy and later China were started.

The European silk trade was first to hear about the new test technologies. Early studies quickly showed that even very fine silk could be tested after certain adaptations of the devices. The test results were more neutral, more meaningful and more precise than the data obtained with traditional testing methods.

Based on the test results, certificates were issued, and these were used to set the commercial values of the products. It was especially important for both trade and the subsequent treatment processes that the test results were accurate, so attention was closely focused on optimizing the testing methods.

The height of the silk business

At the beginning of the 18th century, the “silk courts” in Zurich were world famous, and by 1900 the silk industry was one of the most important industries in Switzerland. Silk processing reached its peak at the beginning of the 20th century. What remains today are a handful of silk producers focusing on niche markets, as well as Testex, founded as “Zuerich Seidentrocknungsanstalt” (institution for silk drying) 175 years ago and the financial institutes which arose to provide capital to support the industry’s profits.

Silk has never been a big business for Uster – only a niche for which Haettenschwiler showed his passion. There were Uster Statistics editions for both spun silk and raw silk, however, not surprisingly, as Haettenschwiler also played an outstanding role in developing Uster Statistics in its early years and through the decades. This story opens another page of Uster history.

Haettenschwiler died this year on August 17. “He was a formative personality for the company and a highly engaged colleague who dedicated his working life to the textile industry with respect to an advanced quality management in staple and filament spinning. Silk was one of his great passions and the development of possible objective quality testing possibilities with Uster products was always his intention, and he was always pushing for investigations and publications,” says Wolfram Soell, senior textile technologist at Uster Technologies AG. “We would like to honor his working life and we should inspire future generations of textile professionals with his story.”

Source: uster.com

FET reports successful campaign at INDEX

Fibre Extrusion Technology, UK, reports a successful showing at INDEX, the nonwovens exhibition in Geneva, Switzerland, which was held Oct. 19-22. Although the company has a long history in supplying meltspinning equipment for the nonwovens sector, this represented its first venture at a dedicated nonwovens show.

FET’s managing director, Richard Slack said, “Techtextil and ITMA have previously been our main exhibitions of choice, but INDEX was an ideal vehicle for FET to launch our new laboratory scale spunbond system, which enables client development of nonwoven fabrics in a number of formats and polymers.”

FET already has spunbond systems in the field, including composite systems which utilize both spunbond and meltspun functions. FET expects growth in global nonwovens technology, partly driven by demand for pandemic-related materials, will continue.

Source: fetuk.com

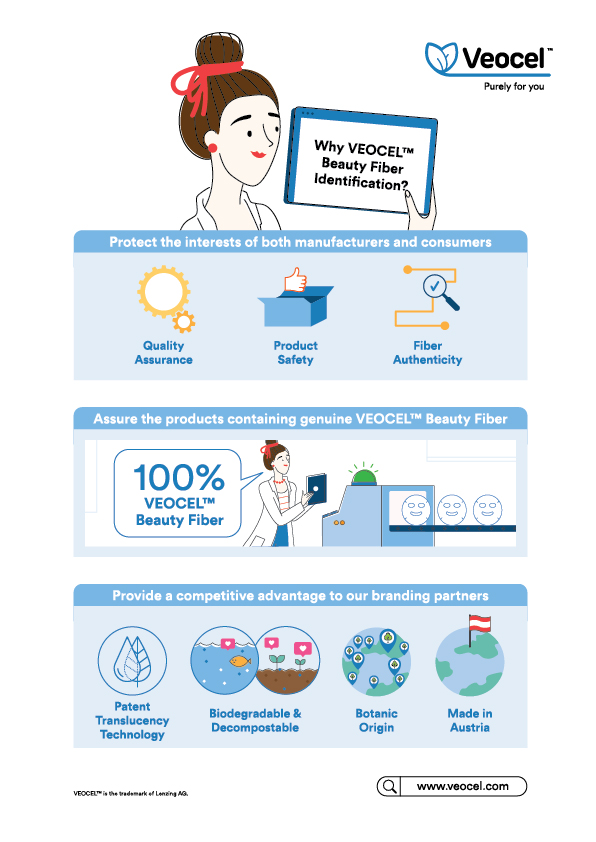

Lenzing introduces Fiber Identification System for Veocel Beauty brand

To address the increasing need for transparency and traceability in materials used in beauty products, Lenzing’s Veocel Beauty brand has launched the Fiber Identification System for Lenzing Lyocell Skin, Lenzing Lyocell Fine Skin and Lenzing Lyocell Micro Skin fibers, which provides traceability, quality assurance and trustworthy communication that genuine premium Lenzing Lyocell Skin fiber types are used in facial sheet masks.

The Fiber Identification System is applicable to the skin fiber types under Veocel Beauty brand, which are ideal for use in facial sheet masks. Made in Austria, the fibers are of botanic origin, biodegradable and compostable. Nonwoven fabrics made of Lenzing Lyocell Skin fiber types also feature Lenzing’s patented Translucency technology, which offers naturally smooth and more translucent facial sheet masks. Lenzing Lyocell Skin fibers are also good for the environment as they are certified CarbonNeutral products with a carbon footprint reduced to net-zero.

The Fiber Identification System can identify fibers in the final products, providing quality control and authenticity assurance for brands against inferior counterfeit products. Products verified by the system also provide consumers with an added level of assurance and peace of mind that materials used in their beauty products are certified clean and made of genuine premium eco-friendly fibers.

Source: lenzing.com

Hyosung Advanced Materials reports strong third quarter results

Having produced a record-high performance in the first half of this year, Hyosung Advanced Materials reported continued strong performance in the third quarter.

Hyosung Advanced Materials’ operating profit in the third quarter increased by 1077.98% from the same period last year (KRW 11.9 billion) to KRW 139.9 billion. The company’s sales also increased by 51.86% to KRW 967.1 billion. Compared to the record-high performance in the second quarter, Hyosung Advanced Materials’ sales and operating profit increased by 10.9% and 18.7% respectively, the highest progress the company has displayed so far.

For tire reinforcements, the company’s key business item, the selling price increased from the previous quarter as the demand for inventory replenishment continues in the upstream automotive industry, leading to an increase in the company’s sales and profitability.

As for carbon fiber, the demand increase has led to a rise in the selling price from the previous quarter, resulting in improvement of both sales and profitability. The industry forecasts that, in line with the hydrogen economy trend, sales and profitability will start increasing full-scale in the fourth quarter, according to Hyosung’s expectations.

In addition, for its aramid business, Hyosung Advanced Materials has been establishing infrastructure to stabilize its extended facilities and expand production volume in the third quarter, which is expected to have a positive impact on the company’s sales and operating profit increase upon commencement of mass production in the fourth quarter.

Source: hyosung.com

Andritz to supply a complete pulp mill to Suzano in Brazil

Andritz received an order from the Brazilian pulp producer Suzano to deliver technology for all main process islands in the fiber production and chemical recovery plant, for Suzano’s Cerrado project in the municipality of Ribas do Rio Pardo, state of Mato Grosso do Sul, Brazil.

Start-up is scheduled for the second half of 2024.

With an annual production capacity of 2.55 million tons, Cerrado will be the world’s largest plant with a single eucalyptus pulp production line. Civil construction, installation, commissioning, and start-up services are also included in the Andritz scope of supply.

Source: andritz.com

ANDRITZ to supply a high-speed spunlace line to Welspun, India

Andritz received an order from Welspun Advanced Materials, India, to deliver a complete neXline spunlace line for the production of nonwoven roll goods and wipes for their new plant in Hyderabad, Telangana.

The line has a capacity of up to three tons per hour. Start-up of the line is scheduled for the fourth quarter of 2021.

The Andritz high-capacity spunlace line will process various types of synthetic or natural fibers, such as polyester, viscose and cotton. The final products will have fabric weights ranging from 25 to 120 gsm, thus covering many applications. The neXline spunlace line also offers the option to integrate a third component from a selection of smart layers, enabling Welspun to also manufacture products for the health care and hygiene sectors.

Welspun is among the largest global exporters of home textiles. Innovation and quality lie at the heart of the company’s success, which already has nonwoven production lines in operation, including needlepunch and spunlace equipment. With its new plant in Telangana, Welspun will significantly increase its existing spunlace capacity and also maintain a broad range of applications as the final products are used in hygiene, home care and industrial cleaning. The new, advanced facility is a 100,000 sqm greenfield development that is part of a larger 1,500,000 sqm industrial complex also accommodating the Welspun floorings facility.

Source: andritz.com

AATCC announces Chapin Award winner

AATCC has named Procter & Gamble’s Elizabeth A. Eggert as the recipient of the Harold C. Chaplin Award for her contributions and support in the area of test method research and development.

Eggert joined AATCC in 1991. She is active on several research committees and has served on some for more than 20 years.

Eggert has served on the Home Laundering Technology committee since 1999 and was secretary of this committee from 2012 through 2019. During this tenure, Eggert rewrote several AATCC monographs on home laundering and was instrumental in implementing major changes to related standards. She has been a member of Color Measurement Test Methods, Antimicrobial Activity Test Methods, and Stain Resistance Test Methods committees since 2000. She also joined the Evaluation of Materials & Products for End Use Performance Test Method committee in 2000 and served as chair from 2005 through 2007. She has been a member of the Colorfastness to Washing Test Methods committee since 2002, and the Electronically Integrated Textiles Test Methods committee since 2016.

Eggert served on the AATCC International Test Methods committee as ISO Spokesperson from 2007 through 2017. In addition, she was appointed to the Technical Committee on Research (TCR) and served from 2002 through 2017; she chaired this committee from 2007 through 2009. She was appointed to the Executive Committee on Research (ECR) in 2004 and chaired this committee from 2010 through 2012. As chair of ECR, she served on the AATCC Board of Directors and as vice-president on the AATCC Foundation Board of Directors.

Eggert also served on a number of other AATCC administrative committees, including the Harold C. Chapin Award Committee, the TCR Service Award Committee, the Awards Oversight Committee, the Committee on Conferences, and the Education Advisory Board. She served on the Subject and Speakers Bureau. Eggert was active in the Midwest Section, serving as secretary in 2002, vice chair in 2003, chair in 2004, and councilor in 2005.

Eggert earned a bachelor’s degree in Textile Science from Ohio State University (OSU) and holds a course certificate from the Harvard School of Business in Disruptive Strategy. She received the New Leader Award from OSU. She has been with Procter & Gamble since 1998 and was recognized with the Procter & Gamble CEO Award. Eggert is also a member of ASTM and is the current Chair of D12- Soaps and Other Detergents, and a member of D13 (Textiles).

The Chapin Award was established in 1958 in honor of Harold C. Chapin, professor of chemistry at Lowell Textile School, who served as national secretary of AATCC for nearly 25 years. The Association will present the Chapin Scroll during the AATCC Textile Discovery Summit Awards Luncheon in Durham, North Carolina, on November 18.

Source: aatcc.org

Indorama Ventures reports a strong Q3 performance on record volumes

Indorama Ventures Public Company Limited (IVL), a global sustainable chemical producer, reported Q3 2021 results amid record production volumes. The company maintained its positive outlook for the rest of the year and 2022, noting caution as headwinds including higher energy prices and supply chain disruptions weigh against resurgent consumer demand.

IVL reported EBITDA of US$478 million in Q3 versus US$552 million in the previous quarter and US$240 million a year earlier. Production volumes reached 3.73 million metric tons, a record, as the global recovery drove consumer demand for IVL’s products.

As the global economy recovers from the pandemic, IVL reported consumer appetite and increasing Brent crude oil prices are testing supply chains and driving a commodity boom, with manufacturers running at full capacity. This has driven increases in freight prices and a shortage of materials.

Mr. D K Agarwal, CEO of Indorama Ventures, said, “The recovery in major economies from the pandemic has benefited us through the year, and we expect strong demand for our products to continue into next year. However, the recovery is uneven as some nations in Asia are slower to reopen, and resurgent consumer demand is being met with higher energy prices and supply chain disruptions. Our business model of integrated and regional supply across a diversified geographical and product base is proving its robustness. Building sustainability across all our businesses is a key focus as our colleagues work tirelessly towards a future ready organization.”

Still, IVL posted a solid YTD performance, ending the first nine months of 2021 with EBITDA of US$ 1,512 million, up 123% YoY. The Integrated Oxides & Derivatives (IOD) segment will start to reap the full benefits of the hot commissioning of the Lake Charles gas cracker (IVOL) in Q4 and beyond, as well as continued advantaged shale gas economics.

In Q3, Project Olympus, the company’s cost saving and business transformation project, achieved US$63 million in efficiency gains, and is on track to achieve a total US$610 million of savings by 2023. IVL also implemented enhanced disclosures in governance, strategy, risk management, and metrics and targets, and launched a comprehensive financial policy and governance structure to accelerate environmentally driven projects.

3Q 2021 Performance Summary

- Consolidated Revenue of US$ 3,867M, an increase of 9% QoQ and 50% YoY

- EBITDA of US$ 478M in Q3 versus US$552 million, a decrease of 13% QoQ and an increase of 99% YoY

- Reported annualized EPS of THB 4.53 and core annualized EPS of THB 4.09

Source: indoramaventures.com

Arxada, Troy agree to merger, aim to bolster position in the area of microbial control solutions

Arxada and Troy Corporation have entered into an agreement to combine two companies. This agreement represents the first strategic deal by Arxada, formerly known as Lonza Specialty Ingredients (or LSI) and owned by private equity funds Bain Capital and Cinven, since the purchase from Lonza Group AG in July 2021. As part of the deal structure, Troy’s owners will invest in the combined company.

“The combination of Arxada and Troy will reinforce our position as a leading global provider of microbial control solutions,” said Arxada CEO Marc Doyle. “Our decision to merge with Troy just four months after our launch as an independent company highlights our ambition and commitment to creating the broadest and most innovative solutions for our customers in this sector. The combination also fits with our strategy of expanding our geographic footprint and the scale and depth of our capabilities by bolstering our manufacturing capacity in MCS beyond North America into Europe and Asia.”

From the proposed transition, Arxada will begin to offer Troy’s 3-iodo propynyl butyl carbamate (IPBA) and will add several production sites, including Newark, New Jersey; Horhausen, Germany; Moerdijk, Netherlands and Kabinburi, Thailand.

“For over 50 years Troy has developed and manufactured preservatives and additives for various industries, enabling our customers to produce high performing, cost-effective and sustainable products,” said Daryl D. Smith, President and CEO of Troy. “The combination of Troy’s strength in architectural coatings and industrial preservation, leadership in IPBC technology and broad range of performance additives perfectly complements Arxada’s strengths in wet state preservation. The joining of the companies will deliver significant added value to our customers going forward.”

The parties will work to close the transaction as soon as possible, subject to obtaining customary approvals. Financial details of the deal have not been disclosed.

Sources: arxada.com and troycorp.com

Evrnu raises $15M in funding to advance fiber recycling technology

Evrnu has raised $15 million Series B financing to scale and meet demand for its fiber regeneration platform, NuCycl. The round was led by FullCycle Climate Partners, which will also serve as a significant project financing partner. Globally diversified supply chain partners and brands are also joining the round as co-investors, including Hansae, Bestseller, and PDS Venture, PDS Multinational Fashions’ venture tech portfolio.

“Over the last few years, we have iterated and fine-tuned NuCycl technologies to meet and exceed the quality and performance demands of the luxury industry,” says Stacy Flynn, CEO & co-founder of Evrnu. “We are now proving these technologies at scale, with short-term plans for global expansion.”

This strategic financing will be used to expand Evrnu’s facilities and operations in South Carolina and service high volumes of NuCycl fibers to the fashion industry. It will also enable key, strategic hires in growth functions and technical roles as Evrnu expedites global deployment of NuCycl to meet the scale required to alleviate dependency on virgin resources and create material emissions reductions throughout the fashion value chain.

Evrnu’s technologies are designed to create a pathway to insert the tens of millions of tons of textile waste that end up in landfills or incinerators every year back into the value chain. The NuCycl platform depolymerizes textile waste and repolymerizes it into fibers that are on par or higher quality than the inputs and can be recycled multiple times.

Having developed the technologies to address the recycling of 90%+ of all apparel, with one patent granted and several others pending, Evrnu is on course to deploy technologies that allow for all textiles to be successfully recycled by 2030.

Enabled with this financing, Evrnu will be rolling out each technology in partnership with global supply chain partners to meet the needs of this emerging market and scale required for material impact. Evrnu has advanced R&D contracts under way, in fashion, as well as in new markets, such as home furnishings and automotive.

Source: evrnu.com

Gaston College breaks ground on Fiber Innovation Center

A groundbreaking ceremony celebrated the start of construction of the Fiber Innovation Center, an expansion of the Gaston College Kimbrell Campus and its Textile Technology Center in Belmont, North Carolina.

The Fiber Innovation Center will provide a world-class facility to develop and test fibers for the advanced materials industry for use in proprietary products developed by national and international clients. When completed, it will be the only North American facility open to industry that will house the entire range of advanced fiber development capabilities where scientists can start with an idea, move to small-scale trials, and work up to a commercially viable product ready for production. Local and regional support from the textile industry and from the North Carolina Office of State Budget and Management is helping make this project possible.

In his comments to ceremony attendees, John Hauser, Ph.D., president of Gaston College, said, “Today this groundbreaking represents a unique partnership that includes the Federal Government, the State of North Carolina, Gaston County, Gaston College, North Carolina State University, and our most important partner—private industry.

“I have worked with many partnerships and collaborations in my 24 years in the community college system, yet none compare to this,” he continued. “I am proud of our work and proud that we are owning our momentum as we join forces to build a world-class Fiber Innovation Center.”

Also speaking at the ceremony were John Dancoff, chairman of the Gaston College Board of Trustees; John Lowery, president of the Gaston College Foundation; Andy Warlick, chairman and CEO of Parkdale Mills; and Davis Warlick, executive vice president of Parkdale Mills.

Parkdale Mills is one of the Textile Technology Center’s vital partners and clients, and its executives have worked closely with Gaston College on the initial design concept of the Center.

“I have not seen in my lifetime in Gaston County a project with such overwhelming support from the state, county, city, academia, philanthropy, and industry,” said Andy Warlick. “The Fiber Innovation Center is the future of the textiles industry.”

The architectural firm of WHN Architects designed the approximately 39,000 square foot facility and Shelco, LLC, is the contractor for the project.

For more information about the Fiber Innovation Center and the Gaston College Textile Technology Center, visit gaston.edu/fic.

Source: gaston.edu

Eurofins Softlines & Leather acquires Modern Testing Services, supporting strategic expansion into consumer products

Eurofins Softlines & Leather – Toys & Hardlines (Eurofins S&L-T&H), part of Eurofins CPT International Business Line, is pleased to announce the acquisition of Modern Testing Services (MTS), a full-service safety and quality services provider for the consumer product industry, as an integral component of its worldwide strategic expansion plan.

Eurofins S&L-T&H, comprised of a global network with a strong footprint in Europe, is a fast-growing services provider specialized in sustainability, quality and safety solutions for the textiles, leather, footwear, toys and hardgoods industry. MTS, with 15 years of industry experience, holds a high reputation and strong customer portfolios, especially in North America.

The acquisition of MTS will further accelerate the pursuit of the Eurofins S&L-T&H goal of becoming a top leader in the testing, inspection and certification (TIC) industry for the consumer products industry. Customers from both companies will enjoy an enhanced synergy from expanded global services network in more than 35 locations from over 20 countries, as well as more robust technical expertise from over 2,000 dedicated and knowledgeable employees worldwide.

Source: eurofins.com

Unifi names Clorox’s Rhonda Ramlo to board of directors

Unifi, Inc., a global manufacturer of recycled and synthetic yarns, announced the election of Rhonda Ramlo to its Board of Directors.

Ramlo is currently vice president & general manager of Strategy, Acquisitions, and New Business Development at The Clorox Company, a position she has held since 2013. Prior to her current role, she served as vice president & general manager of The Clorox Company’s Laundry and Water Filtration businesses. Before joining the Clorox Company, Ms. Ramlo spent over 15 years in various executive leadership positions with Dreyer’s Grand Ice Cream Holdings, Inc. She also currently sits on the board of directors of two privately held consumer packaged goods companies, Nuun, Inc. and REDD Bar. Ramlo received her bachelor’s degree in economics from the University of California, Berkley and obtained her MBA in general management from Harvard Business School.

Al Carey, executive chairman of Unifi, stated, “We are very excited to welcome Rhonda to Unifi’s Board of Directors. She brings nearly three decades of experience in strategic and business development consulting. Rhonda has a wonderful track record in brand strategy, marketing, sales, and innovation. We are confident that her contributions and expertise will enhance Unifi’s growth potential.”

Source: unifi.com

Indorama Ventures issues THB 10B Sustainability-Linked Bond

Indorama Ventures Public Company Limited (IVL), a global sustainable chemical company, issued a THB 10 billion triple-tranche Sustainability-Linked Bond (SLB). The issuance of the bond is part of the company’s aim to showcase its commitment to sustainable growth. It is the largest SLB issued in Thailand and the first offered to both institutions and high-net-worth investors.

The SLB is linked to IVL’s performance of reducing GHG emissions intensity by 10% by 2025 (from a 2020 base), increasing recycling of PET bale input to 750,000 tons per year by 2025, and achieving 25% renewable electricity consumption in 2030.

The bond is part of IVL’s financing strategy across a range of instruments linked to the company’s sustainability targets. It is aligned with internationally accepted standards including International Capital Markets Association’s (ICMA) Sustainability-Linked Bond Principles and the Loan Market Association’s (LMA) Sustainability Linked Loan Principles.

The triple-tranche structure includes 5-, 7-, and 10.5-year tenors, offering coupons of 2.48%, 3.00% and 3.60% per year respectively, targeting asset managers, commercial banks, insurance companies, cooperatives and high-net-worth individuals. With the orderbook peaking at over THB 17.8 billion due to strong interest in the sustainability-linked instrument, oversubscription was around 3x over the planned issuance amount of THB 6 billion with a green shoe option of THB 4 billion. In view of the strong orderbook from the investors, the company decided to exercise the green shoe option and increased the issuance to THB 10 billion, setting a new benchmark as the largest SLB transaction in Thailand. IVL appointed Bangkok Bank, Kasikorn Bank, Krungthai Bank, Siam Commercial Bank, and The Hongkong and Shanghai Banking Corporation Limited, Bangkok Branch as arrangers and bookrunners for the transaction.

On 23 September 2021, the bond was assigned an AA- rating and a “stable” outlook by TRIS Rating following a strong recovery of petrochemicals and derivatives and IVL’s growing profitability.

Under the terms, all tranches must purchase Energy Attribute Certificates (EAC) or voluntary carbon offsets in the event of failure to meet the sustainability performance targets (SPT). The testing dates for tenors with a maturity of 5 and 7 years are 31 December 2025, and 31 December 2030 for the 10.5-year tenor. SPT performance will be independently verified upon the testing dates. Proceeds for the issuance will be used to finance IVL’s corporate working capital and refinance existing debt.

In recent years, IVL secured loans linked to improvements in the company’s sustainability performance as a global leader in environmental, social and governance (ESG) integration. These included Thailand’s first Green Loan of USD 200 million and EUR 200 million from Japan’s Mizuho Bank, Thailand’s first cross-border Sustainability-Linked Ninja Loan worth USD 225 million from 16 institutions in Japan and a Blue Loan of USD 300 million arranged by International Finance Corporation and funded by Asian Development Bank and DEG.

Source: indoramaventures.com

Indorama reshuffles, adds to management council, elevating Fibers and Integrated Oxides & Derivatives businesses

Indorama Ventures Public Company Limited, a global sustainable chemical company, announced it has reorganized and added to the Indorama Management Council (IMC), rotating experienced executives and adding the COOs of the Fibers and Integrated Oxides & Derivatives (IOD) segments.

The elevation of Christopher Kenneally, COO of Fibers, and Alastair Port, COO of IOD, to the IMC is expected to enable more agile decision making as these executives build their high-growth segments into self-sustaining organizations that maximize value for IVL stakeholders, according to the company. The appointments are effective immediately.

In a rotation of roles, Mr Sanjay Ahuja, the current CFO of IVL, will switch to Interim COO of Combined PET (CPET) for a period of two years, effective January 2022, as part of a rotation of senior expertise across the IMC. He will report to D K Agarwal as CEO, who will take on additional broader responsibilities as CFO. The CPET role rotation will enable new dynamism in this largest segment of IVL and establish a self-sustaining organization for the permanent successor that IMC selects over this period. Agarwal will be supported by Ashok Jain in an enhanced role as controller, covering Banking & Finance, Global Consolidation, Taxation and M&A.

Further, Klaus Holz will join the IMC as chief human resources officer, effective 1 January 2022. He replaces Roberto Bettini who will retire at the end of 2021.

Source: indoramaventures.com

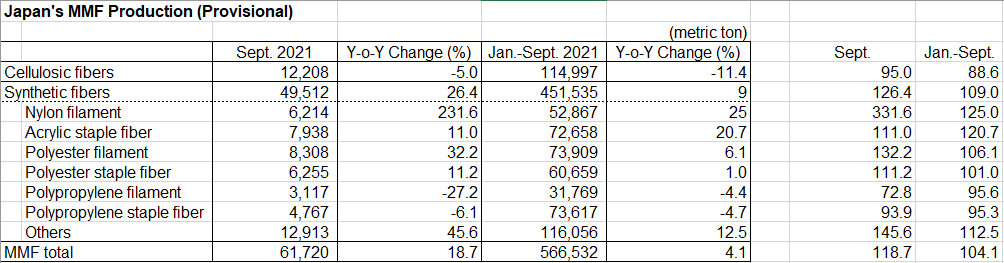

Japan’s man-made fiber production increases 18.7%

According to the Japan Chemical Fibers Association, the nation’s production of manmade fibers in September 2021 increased by 18.7% compared to the same month of last year to 61,720 (metric) tons. Of this, the production of synthetic fibers grew by 26.4% to 49,512 tons.

September production of four major synthetic fiber items is as follows: nylon filament (NF), 6,214 tons (up 231.6%); acrylic staple fiber (ASF), 7,938 tons (up 11.0%); polyester filament (PF), 8,308 tons (up 32.2%); and polyester staple fiber (PSF), 6,255 tons (up 11.2%).

Meanwhile, producers’ ending stocks of MMF amounted to 99,036 tons (up 0.5% from the previous month, but down 4.5% from the year before). Of this, those of synthetic fibers totaled 72,310 tons (up 0.5% but down 4.3%, respectively).

Stocks of major items were: NF, 9,121 tons (up 6.5% from the previous month); ASF, 14,399 tons (up 13.9%); PF, 7,874 tons (down 6.5%); and PSF, 14,211 tons (down 10.0%).

Source: jcfa.gr.jp

AATCC offers donors an opportunity to ‘weave’ a legacy during AATCC Week of Celebration

The AATCC Foundation is offering a new way to “weave” a legacy at the AATCC Week of Celebration, November 15-19, 2021. In addition to foundation donations to support students and the future of the textile industry, donors of $100 or more during the Week of Celebration will weave yarns into a tapestry to be displayed at the AATCC Technical Center.

The AATCC’s three-year (2019-2021) 100 for 100 campaign aims to fully endow $100,000 in scholarships. Contributors throughout the campaign receive a gold pin to commemorate their participation.

The tapestry project is limited to donors at the AATCC Week of Celebration. The Week of Celebration includes Fall Research Committee Meetings, Textile Discovery Summit, and the tour/time capsule burial to end the week. Learn more and register for all events at www.aatcc.org/100th.

To make an online donation and receive your pin, visit www.aatcc.org/foundation.

Source: aatcc.org