In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: October 30, 2023

Zara Owner Inditex to Buy Recycled Polyester From US Start-Up

Zara-owner Inditex, the world’s biggest clothing retailer, has agreed to buy recycled polyester from a U.S. start-up as it aims for 25% of its fibers to come from “next-generation” materials by 2030.

As fast-fashion retailers face pressure to reduce waste and use recycled fabrics, Inditex is spending more than $74 million to secure supply from Los Angeles-based Ambercycle of its recycled polyester made from textile waste.

Polyester, a product of the petroleum industry, is widely used in sportswear as it is quick-drying and durable.

Under the offtake deal, Inditex will buy 70% of Ambercycle’s production of recycled polyester, which is sold under the brand cycora, over three years, Inditex CEO Oscar Garcia Maceiras said at a business event in Zaragoza, Spain.

Garcia Maceiras said Inditex is also working with other companies and start-ups in its innovation hub, a unit looking for ways to curb the environmental impact of its products.

“The sustainable transformation of Inditex … is not possible without the collaboration of the different stakeholders,” he said.

The Inditex investment will help Ambercycle fund its first commercial-scale textile recycling factory. Production of cycora at the plant is expected to begin around 2025, and the material will be used in Inditex products over the following three years.

Milliken Invests in Sustainable Carpet Maintenance Company

Global diversified manufacturer Milliken & Company has invested in Orak, a Paris-based carpet maintenance and flooring reuse company, as a strategic sustainability enabler for its floor covering business. The relationship marks the beginning of a new generation of sustainable floor covering solutions, and it is set to change the way the industry thinks about waste and its approach to the circular economy.

Orak’s Optimal Karpet line of upcycled premium carpet tile has quickly become the leading solution for carpet customers seeking to reduce the carbon footprint of their construction and renovation projects. With Milliken’s investment and partnership, Orak will improve and expand its product offerings to a broader range of customers by managing all the stages in the life of clients’ carpets to guarantee excellent quality reuse. As Orak’s exclusive industry partner, Milliken’s customers will receive access to Orak’s inventory of upcycled carpet tile, all of which aligns with Milliken’s N/XT Life™ circularity program.

Truetzschler Donates $1.2M in Equipment to Fiber Innovation Center

The Gaston College Fiber Innovation Center, a world-class facility focused on the future of the textile industry, has received a $1.2 million equipment donation from Truetzschler, a German textile machinery manufacturer, building upon its anticipated opening next year.

“Truetzschler is excited to be a part of the new state-of-the-art Fiber Innovation Center at Gaston College and proud to show our commitment to the textile industry for the future,” said Greg Duncan, vice president of Sales, Spinning at American Truetzschler.

The donated equipment features technology that is focused on circularity and reducing the carbon footprint of fiber and textile production. Once finished, the facility in Belmont, N.C., will be the only facility in the world where scientists, entrepreneurs and industry leaders can take a fiber idea and convert it to a textile product under one roof. Features of the innovation center include a new polymer development lab, a fiber extrusion line and yarn preparation capabilities thanks to the Truetzschler donation.

For over 75 years, Gaston College’s Textile Technology Center has provided technical assistance and support to the textile industry in North Carolina and around the world. While the industry has evolved, the Center has remained committed to helping companies and entrepreneurs meet new and emerging needs for developing and testing advanced fibers and fabrics.

The Textile Technology Center and Fiber Innovation Center allow students to get hands-on experience with the latest technology and equipment used in research and development, testing, and production processes for the textile industry.

GUTEX Produces First Fibers for Insulation Board with new ANDRITZ Fiber Preparation System

Wood fiber insulation board manufacturer GUTEX has successfully produced its first fibers with its new ANDRITZ fiber preparation system in Eschbach, Germany. This is the second system ANDRITZ has delivered to GUTEX.

The scope of supply comprised a complete fiber preparation line, including a debarking and chipping line as well as the steel structure, piping material and installation work.

GUTEX is one of Europe’s pioneers in ecological insulation solutions. The family business based in the German Black Forest started making wood fiber insulation products back in 1932. In 2006, GUTEX was the first company to start producing wood fiberboard insulation with a homogeneous raw density profile using an innovative drying process. This technique allows GUTEX to manufacture single-layer wood fiber insulation board up to 240 mm thick and with significant quality advantages.

Quantum Materials Acquires Innegra™ Portfolio of High-Performance Fibers

Quantum Materials, LLC, a vertically integrated manufacturer of multifilament and monofilament yarns, elastomeric woven suspension fabrics and industrial textiles, has acquired the Innegra™ portfolio of patented high-performance fibers and materials.

Innegra will serve as a foundational product to support Quantum’s growth of new technical and industrial textile solutions for the composite and textile markets.

Quantum has accelerated its capital expenditure plan over the last three years to expand the company’s manufacturing asset base to meet increased demand for domestic textile production. The expansion, which included investment in equipment and infrastructure to support the production of Innegra, has allowed the company to seamlessly merge the Innegra business into its operations post-acquisition and successfully service the brand’s current customer base.

Mara Hoffman Unveils Dress Made from Textile Waste

Sustainable luxury designer Mara Hoffman has released her first dress design using Circ® Lyocell, a filament lyocell derived from 50% recycled textile waste.

Dubbed “The Dress that Changes Everything,” this collaboration between Mara Hoffman and Circ, the fashion technology company that recycles polycotton textile waste back into new fibers, is the first time Circ Lyocell is being used in the luxury market. The dress also heralds an ongoing partnership as the designer announces her commitment to transitioning to from virgin lyocell to Circ Lyocell in her collections over the next three years.

Chinese Textile Players Investing $101 Million in Egypt

Chairman of the Suez Canal Economic Zone (SCZONE), Walid Gamal El-Din visited Shanghai recently, where he signed agreements with Chinese investors and businessmen, primarily focusing on the localization of various industries within the SCZONE’s ports and regions. Notably, the textile sector emerged as a key area of interest during these discussions.

The SCZONE in collaboration with several leading Chinese companies, has officially signed agreements to establish textile projects valued at $101.3 million. These projects will be situated within the West Qantara Industrial Zone.

ANDRITZ to Relocate and Upgrade Fiber Line for Yueyang Forest & Paper, China

International technology group ANDRITZ will relocate and upgrade a fiberline for Yueyang Forest & Paper to produce premium quality fibers for its new paper machine.

The P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) line was originally supplied by ANDRITZ in 2011 to the mill in Yuanjiang city, Hunan province. ANDRITZ will now transfer it to Yueyang city, Hunan province, where it will process mixed hardwood for the production of printing and writing papers.

By adding new high-efficiency equipment and refurbishing existing machines, the upgrade will raise the line’s minimum design capacity to 650 admt/d and improve fiber quality while saving energy and chemicals. Start-up is scheduled for the second half of 2024.

Spinnova Unveils Sustainable Denim at Kingpins Trade Show

With a global market of 3.1 billion pairs in 2022, denim jeans could easily be considered a wardrobe staple. Despite this, there has been limited innovation to address the many sustainability challenges of denim production, such as water and resource intensity, heavy chemical use and dyeing, as well as limited recyclability when blended with materials such as polyester and elastane.

Sustainable textile material company Spinnova recently presented the first blended denim fabrics made with wood based SPINNOVA® fiber at the annual Kingpins denim trade show in Amsterdam. The pilot products showcase Spinnova’s technology’s potential to improve the sustainability of denim on multiple fronts. When SPINNOVA® fiber is produced from certified eucalyptus pulp, it has various environmental benefits such as 99% less water consumption and 74% fewer CO2 emissions compared to conventional cotton. The fiber spinning process uses zero harmful chemicals and thanks to the unique mechanical process, the fiber has a natural hand-feel. Finally, the raw material used to make SPINNOVA® fiber can be traced back to its origin.

The denim industry doesn’t compromise on quality, which has been a challenge for denim manufacturers exploring new materials in the past. While most man-made fibers lack the quintessential, sturdy feel of cotton-based denim, early tests have shown that denim produced with a blend of SPINNOVA® and cotton maintains those qualities and meets the aesthetic requirements of denim.

Gildan Closing One of Two Salisbury Plants

Gildan Yarns is laying off 258 workers by closing one of its plants in Salisbury, North Carolina, according to a notice with the N.C. Department of Commerce.

Employees are being offered the opportunity to transfer to other area operations in Salisbury and Mocksville. The plant is expected to close on Dec. 8, 2023.

“This facility is being closed as part of Gildan’s plan to continue to balance production and inventory levels to drive an efficient and competitive manufacturing platform,” said Jim Powers, director of human resources at Gildan in Sanford, in a letter to state officials.

Last year, the company closed its distribution center in Mebane and laid off 128 employees.

The Montreal-based company is one of the world’s largest manufacturers of apparel, underwear and socks. Its retail brands include American Apparel, Gildan activewear, Goldtoe, and Peds.

In December 2021, the company spent $168 million to purchase Frontier Yarns, which has two facilities in Mayodan. It then sold one of the yarn-spinning manufacturing plants in Mayodan to Milliken in 2022.

The company has 45,000 employees around the world. In the second quarter, it produced revenue of $840 million, down from $896 a year earlier. Its net income was down slightly to $155 million in the second quarter from $158 million last year.

Coats American Laying Off 51 at Kings Mountain

Charlotte, North Carolina-based Coats American is laying off 51 workers at a facility in Kings Mountain, according to a filing with the N.C. Department of Commerce.

The layoffs are expected to occur in late November and will be permanent, according to the filing. The jobs range from spinning operator to machine operator and maintenance team leader.

The parent Coats Group, which makes yarns, threads and zippers, is based in Great Britain.

In early 2020, Coats Group purchased Pharr High Performance as the Gaston County company exited the yarn business after 80 years, according to The Charlotte Observer.

Recycler Renewcell Replaces CEO

Swedish textile recycler Renewcell announced the departure of its CEO this week, after a weaker-than-expected sales update last week sent its share price plummeting. The company board appointed Magnus Håkansson as the new acting CEO.

The company, which counts H&M Group amongst its backers and claims to have built the world’s first commercial scale chemical textile recycling facility, has been ramping up production with a view to reach break-even on a cash flow basis by the end of the year. But lagging sales mean that’s now unlikely, the company said Thursday, prompting a sell off that has knocked nearly 80 percent off its share price.

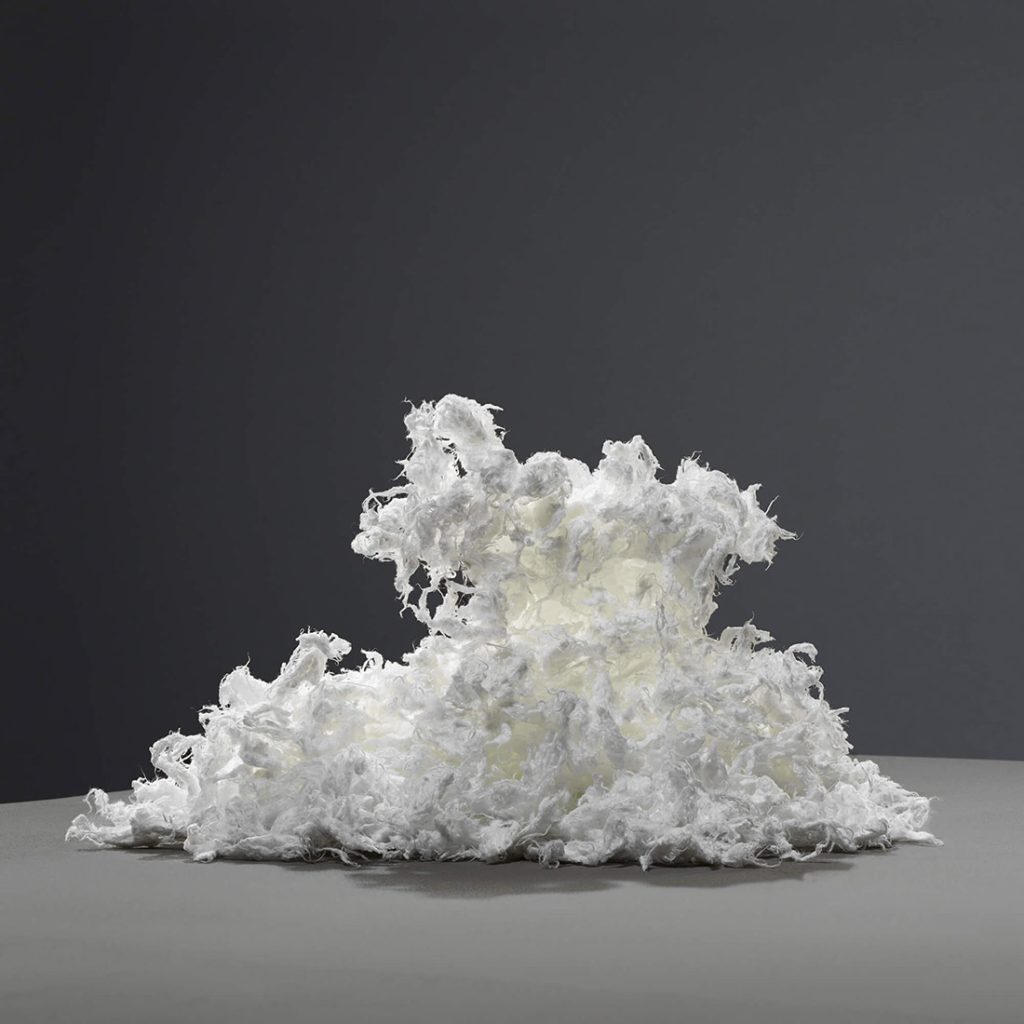

PFNonwovens Launches Product Portfolio Based on 100% Renewable and Compostable Materials

Global nonwoven fabric manufacturer PFNonwovens, a leading innovator in the nonwovens industry, announced the launch of its newest sustainable nonwoven product portfolio based on 100% renewable resin, leveraging the latest Reicofil 5 technology. The portfolio is highlighted by a number of breakthrough materials made entirely from polylactic acid (PLA) resins. These products are setting new standards for eco-friendly spunmelt nonwovens and reinforce PFNonwovens’ commitment to sustainability and environmental stewardship.

The commercial launch of the new bio-based nonwoven products, produced from 100% PLA and enabled by the Reicofil 5 technology, is the most recent step in the company’s drive to address environmental challenges. These innovative materials set new standards for eco-friendly spunmelt nonwovens, while delivering the performance and quality levels expected in applications such as advanced hygiene products, filtration, medical and many others. These new products composed entirely of PLA (from NatureWorks LLC) are industrially compostable and include both spunbond and SMS structures. Developing products that met the goal was a challenge and was enabled by the state-of-the-art Reicofil 5 technology.

Sonae Arauco Chooses ANDRITZ Pressurized Refining System

International technology group ANDRITZ will supply a pressurized refining system to Sonae Arauco Deutschland GmbH’s mill in Meppen, Germany, to produce wood-based insulation products. This will be the 15th insulation board production line equipped with an ANDRITZ pressurized refining system, confirming ANDRITZ’s strong position in the industry.

The new line will process a mixture of wood chips from different types of timber to produce insulation boards for the construction industries. Start-up is scheduled for 2025.

Bernd Runge, Construction System Project Manager, Sonae Arauco Deutschland, said: “The fiber preparation systems from ANDRITZ offer significant economic and environmental benefits. We are confident that ANDRITZ’s advanced technology will meet our requirements and ensure the production of high-quality insulation products.”

At the heart of the new line will be a highly efficient pressurized refining system featuring a proven 44-1CP single disc refiner and a 14” plug screw feeder to ensure improved fiber quality with reduced electrical and thermal energy consumption. The scope of supply also includes a C-feeder and a pressurized digester with counterflow and steam regulation system.

With 23 industrial and commercial units in 9 countries and about 2,600 employees, Sonae Arauco is one of the world’s largest producers of wood-based panels.

Suominen Appoints SVP, Americas

Thomas Olsen, MBA, has been appointed senior vice president, Americas business area at Suominen. He will be a member of Suominen’s Executive Team and report to president and CEO Tommi Björnman. Olsen will start in his new position on Nov. 1, 2023.

“Thomas has a strong experience in leading sales in global organizations. He also has industry knowledge and proven record in successfully executing company goals. I am sure he will be a valued member in our Executive Team and support us in our journey towards profitable growth”, said CEO Björnman.

Glatfelter, Mundeo, Sequel to vie for Hygienix Innovation Award™

INDA, the Association of the Nonwoven Fabrics Industry, revealed the three finalists that will compete for the Hygienix Innovation Award™. Glatfelter, Mundeo and Sequel will present their new absorbent hygiene products to senior-level leaders at Hygienix, Nov. 13-16, The Roosevelt New Orleans Hotel in New Orleans. The three are:

Glatfelter: GlatPure™

GlatPure™ is a range of bio-based absorbent hygiene components derived from renewable materials. This product range consists of a variety of plant-based and natural topsheets, an acquisition distribution layer, an absorbent core, a newly improved backsheet, and a landing zone. Crafted from 100% renewable fibers and biodegradable materials, and enriched with bio-based binders, GlatPure™ stands as the industry’s first fully functional, fossil-fuel free range of solutions.

Mundao: Diap’Earth®

From nature to nature: Mundao brings to market DIAP’EARTH®, an industrially compostable baby diaper. This diaper provides a circular solution to the AHP waste issue. Ecoconception (DIAP’EARTH is a bio-based & plastic free diaper) makes it possible to compost the diaper in an industrial composting facility to turn it into carbon where it can become fertilizer for soil. DIAP’EARTH has been successfully composted in major French cities.

Sequel: The Sequel Spiral™ Tampon

The Sequel Spiral™ Tampon features a proprietary spiral design that is engineered to be more fluid mechanically efficient, meaning it is designed to absorb more evenly and not leak before it’s full. In August 2023 the Sequel Spiral™ Tampon received clearance from the United States Food and Drug Administration (FDA) as a medical device and the company will now begin a series of consumer trials, with broad availability expected in Q1 of 2024.

The winner of the award will be announced at the end of the event, Thurs., Nov. 16 at 11:30 am. Last year’s award recipient was Pads on a Roll™ by Egal Pads. Pads on a Roll is a wrapped super-thin absorbent period pad that dispenses like toilet paper in public bathroom stalls, preventing the personal embarrassment of not having a menstrual product when needed.

In addition to the award presentation, the Hygienix™ conference will focus on consumer-centric innovations, the circular economy, raw material advancements in sustainability, opportunities for advanced recycling in absorbent hygiene, optimizing the packaging footprint, new approaches for odor control, and market trends and drivers. Plus, INDA’s Government Affairs office will be in attendance to provide insights into recent regulatory and legislative issues. Participants can learn about how the current political landscape could affect the nonwovens industry.

The Nonwovens Institute Expands ISO-Accredited Filtration Testing Lab

The Nonwovens Institute (NWI) announced its newly expanded Filtration Testing Lab, featuring services for facemasks and respirators, along with filter media for automotive, HEPA and HVAC applications.

Importantly, NWI’s Filtration Testing Lab is A2LA Accredited for ISO 17025*, enabling it to meet NIOSH requirements for testing materials used in respirators, and it is outfitted with equipment to perform ASTM F2299 testing for the measurement of Particle Filtration Efficiency (PFE) at 0.1 microns.

In addition to NWI’s Filtration Testing Lab, NWI offers a fully equipped Analytical and Physical Testing Lab with more than 60 tests available for nonwoven materials. NWI also offers lab- and pilot-scale capabilities for Fiber Spinning, Meltblown, Spunbond and Hydroentangling, Staple/Carded Nonwovens, among others.

NWI will be exhibiting at FiltXPO™ 2023, Oct. 10-12, Navy Pier in Chicago. Visit NWI at Booth No. 826 to learn more about its Filtration Testing Lab and capabilities.

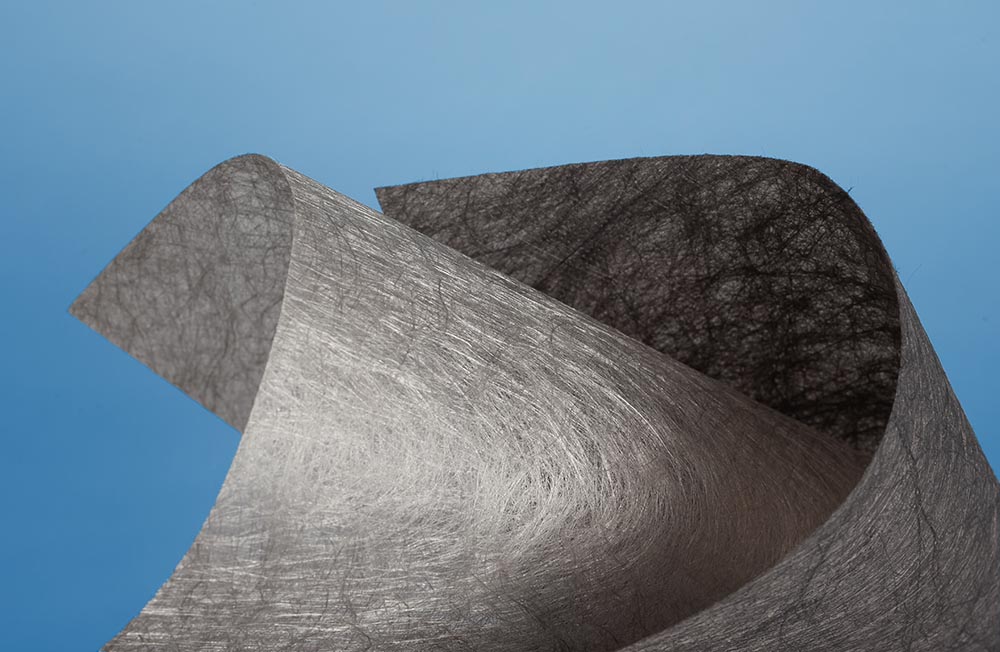

Freudenberg Adds Eco-Friendly Options for Carpet Backings

Freudenberg Performance Materials is extending its recently introduced ECO range of sustainable nonwoven carpet backings: Lutradur ECO-R and Colback ECO-R backings contain high percentages of recycled raw materials. With its ECO portfolio Freudenberg supports carpet manufacturers in their transition towards an increasingly sustainable product offering.

Freudenberg’s spunbond nonwoven primary and secondary carpet backings contribute to manufacturers’ easy and efficient production processes as well as to high-performance end products. The company is now extending its ECO range in Europe with Colback ECO-R and Lutradur ECO-R backings that contain a recycled content of between 51 and 90 %. Replacing virgin raw materials with recycled polyester saves on natural resources and improves the carbon footprint of end products. The ECO-R backings are specifically suitable for carpet tiles, broadloom, dust control mats and automotive option mats.

The company launched its ECO range for sustainable primary backings earlier this year with the introduction of the ECO-RE resource-efficient backings that use less raw materials and support end product recyclability. To achieve this, Freudenberg R&D teams further developed the company’s proprietary yarn production technology allowing for extremely thin filaments.

“With the extended ECO range, Freudenberg now offers a variety of different solutions supporting carpet manufacturers in making sustainable choices to suit their ambitions and processes”, said Albert Hammerschmied, Director for EMEA carpet business with responsibility for New Business Development and Sustainability. “Freudenberg is a long-term supplier to the industry with a strong history of developing tailored solutions for and with our industry partners. The continuous development of backings with recycled content is one result of these efforts.”

Freudenberg manufactures carpet backings with recycled content in Europe, North America and China, allowing customers within the world regions to further optimize their CO2 footprint thanks to short transportation routes.

Agricultural Textiles Market worth $20.2 billion by 2028 Globally, at a CAGR of 4.8%

The global Agricultural Textiles Market is projected to grow from $15.9 billion in 2023 and is projected to reach $20.2 billion by 2028, at a CAGR of 4.8%, between 2023 and 2028 period, as per the recent study by MarketsandMarkets™. The demand and use of agricultural textiles are rapidly increasing due to the growth in outdoor and controlled-environment applications. The increasing urbanization, rising standards of living, and rising income levels is growing the agricultural textile market.

Renewcell’s Circulose Network Grows to 116

Swedish textile recycler Renewcell is rapidly broadening its community of yarn and textile partners across the globe, including several denim mills.

After launching its Circulose Supplier Network in July 2023, the group this week announced that it has grown its membership from 47 to 116 yarn spinners, knitters, mills and other textile supply chain stakeholders across 15 countries, adding diversity and global reach.

New members hail from Vietnam, Taiwan and the Czech Republic, among other nations, adding a variety of qualities made from Circulose, the recycled and recyclable cellulosic pulp. The network has also onboarded home textile suppliers for the first time, including India-based Sharadha Terry Products and Kadri Mills, as well as China’s Yang Tsu. According to Renewcell, these strategic additions open up Circulose to more categories within the textile sector.

Heberlein Launches DTY Interlacing Jets

Heberlein, a supplier of air interlacing and air texturing jets, has launched a new series of interlacing jets for Drawn Texturized Yarn (DTY) called Advanced Performance (APe) and Advanced Performance high stability (APh) jets. These jets bring cost savings in compressed air usage and ensure knot stability, making them attractive investments for businesses aiming for better profitability.

Last year, the global textile machinery market experienced a noticeable slowdown, with a 13% decrease in shipments of draw texturing spindles worldwide. China accounted for a significant 86% of this decline. However, Heberlein, drawing from its past experiences during economic downturns, remains optimistic about the DTY segment, expecting a strong recovery in business.

Heberlein plays a crucial role in enhancing manufacturers’ performance by developing specialized components for processing synthetic yarns, especially filament yarns. Through extensive testing and utilizing the latest flow simulations, Heberlein has created the Advanced Performance jets, aimed at improving production efficiency. These new jets not only enhance production speed but also enable substantial process optimizations and energy savings in yarn production.

Heberlein’s launch at ITMA 2023 of the new APe series – with the capability to reduce compressed air consumption by 15% with the same number of knots – had DTY yarn producers reaching for their calculators. For example, a texturizer in Italy planning to replace a P142 jet (P-series) with an APe142 worked out cost savings of USD 120 per day for a 288-position machine with a working pressure of 3 bar. The figures were based on local electricity costs of 0.12 KWh for 1 Nm3. Effectively this was a saving of 5 dollars every hour.

RadiciGroup Showcasing Functional Fabric

Radilon® Chill-fit is the new RadiciGroup solution to maximize the breathability and freshness that a fabric can offer. It is the result of extensive research and development that has led to the creation of a highly functional nylon yarn capable of ensuring thermal regulation of the fabric without the need for additional treatments.

Radilon® Chill-fit provides the wearer with a pleasant feeling of comfort and freshness for an extended period while offering high protection against UV rays.

Marco De Silvestri, Sales & Marketing manager of the Advanced Textile Solutions Business Area, explained: “Our efforts have always been focused on optimizing the technical performance of yarns, as in the case of the new Radilon® Chill-fit, but we also strive to improve the environmental performance of the various sectors we work with, such as sportswear, athleisure, workwear, and many others, thanks to our specialized, traceable and low impact products.”