Sparkle makes planet-friendly period care products from renewable plant-based ingredients that do not contain conventional petrochemical-based plastics (such as polypropylene or polyethylene). Recently, IFJ caught up the Sparkle’s CEO and co-founder, Chirag Virani to learn more about the company and the impact it is making on the marketplace.

International Fiber Journal: Please give us an overview of your company, and how it came about.

Chirag Virani: As a male, my knowledge about periods and pads was very limited before I started working with different NGOs. I was aware of the biological process, but I had no idea about the various physiological or socio-economic issues that menstruators faced during their periods when they did not have access to period products.

After completing my grad program at UC Berkeley, I wanted to put my engineering and business skills to some good use while volunteering at different NGOs in Kenya, Tanzania, Vietnam, South Africa, India, and Costa Rica. I participated in many outreach programs including medical camps, HIV counseling, teaching and feeding programs. Through those experiences, I learned about the problems that millions of girls and women faced during their periods. Girls missed school, and women missed work simply because they did not have access to sanitary napkins. In fact, many of them used unhygienic rags, papers, or ash to manage their periods. In many developing countries, menstruating girls and women are still considered ‘impure’ or ‘dirty.’

In 2017, Hetal Virani (Sparkle’s co-founder and my life partner) and I started an NGO, United World Foundation, to donate sanitary pads to menstruators in need. We started purchasing conventional sanitary pads that were available in the market and began donating them to different NGOs that I had personally worked with in the past. During this process, we realized that the more plastic a pad had inside, the cheaper it was.

As an engineer, I began to dig deeper into the different layers and realized that conventional pads contained up to 90% plastic; the top layer was made from polypropylene, the back sheet made from polyethylene, and the absorbent core made from sodium polyacrylate, a crude oil derivative. Since roughly half of the world’s population menstruates, each year, around 300 billion period products are used and discarded across the globe, all of which remain unchanged in landfills for over 500-600 years.

We realized that while we were donating pads, we were solving the problem of accessibility, but we were creating another problem – waste generation from non-biodegradable sanitary pads made from conventional plastics.

We realized that banana fibers were naturally absorbent and highly effective at locking away menstrual fluid. We started conducting research on how we could transform this agro-waste into absorbent hygiene products, and that’s how the journey of Sparkle started.

That’s when we started exploring the possibility of making sustainable alternatives to conventional sanitary pads.

The fact that I came from a family of farmers who happened to have a banana plantation was the last missing piece of the puzzle. Banana plants grow in around nine to 12 months, and once these bananas are harvested, their stems become agro-waste. Farmers either burn these stems, or have to pay extra labor to get them removed from their farms.

We realized that banana fibers were naturally absorbent and highly effective at locking away menstrual fluid. We started conducting research on how we could transform this agro-waste into absorbent hygiene products, and that’s how the journey of Sparkle started.

IFJ: Tell us how the decision came about to create a natural and biodegradable sanitary napkin.

Virani: Conventional, single-use, disposable sanitary pads are highly engineered products, and contain up to 90% plastics, artificial fragrances and dyes that may cause skin rashes and irritation. They are designed by keeping both high-speed machine runability as well as low raw material costs in mind. Each layer of the sanitary pad has a very specific function with strict performance and technical requirements that the finished product needs to meet. Made with mass-produced petrochemical by-products, such as polypropylene, polyethylene, sodium polyacrylate, and other synthetic fibers, they are designed to offer a high-performing product at the lowest possible price.

However, they are not designed to keep sustainability or the product’s end-of-life scenario in mind; this is a big environmental problem we must address, and one we chose to attempt to tackle.

Globally, around 300 billion period products are used and discarded every year, resulting in millions of tons of sanitary pad waste. In North America alone, around 20 billion period products are disposed of in landfills every year, and around 12 billion of those are menstrual pads. In India, around 15 billion used sanitary pads end up in landfills every year.

We focused on two main aspects:

- Choosing sustainable ingredients that allowed us to develop products that could perform well

- Keeping the entire product life-cycle in mind, including what would happen to the product at the end of its life after its disposal

We started by replacing the conventional plastic from the different layers of the sanitary pad. The top sheet of the Sparkle pad is made from cellulose fibers, the absorbent core is also made from a porous network of cellulose fibers, and the back film is made using TUV Austria certified home compostable materials.

We have designed the Sparkle pad in such a way that whether it ends up in a landfill, or in an incinerator, or in a compost pit, it offers a more sustainable alternative when compared to its conventional counterpart.

IFJ: Describe the product and its benefits for the environment and the consumer.

Virani: Since Sparkle pads are made from sustainable plant-based materials and do not contain conventional plastics, artificial fragrances, or dyes, they are better for the environment as well as the consumers’ health.

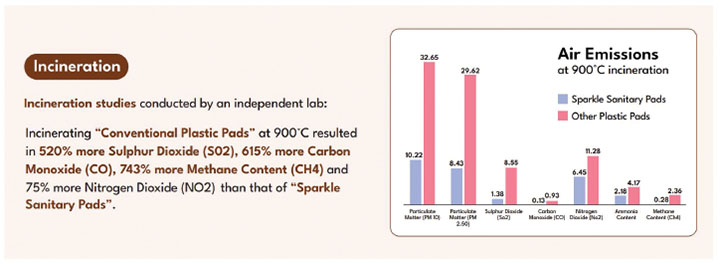

Sparkle pads are USDA-certified bio-based products with 86% biobased content, which means we use ingredients that reduce our dependence on fossil based resources. In order to evaluate the emission profiles of Sparkle pads vs. conventional pads, our products were tested by an independent third-party organization. Sparkle products are also vegan approved by the UK’s Vegetarian Society, and dermatologist-tested in the U.S. as hypoallergenic.

It was observed that incinerating “Sparkle Sanitary Pads” resulted in significantly lower air emissions compared to incinerating “Other Plastic Pads.” More specifically, incinerating “Other Plastic Pads” at 900 degrees C resulted in 520% more sulfur dioxide (S02), 615% more carbon monoxide (C0), 743% more methane content (CH4), and 75% more nitrogen dioxide (NO2) than that of “Sparkle Sanitary Pads.”

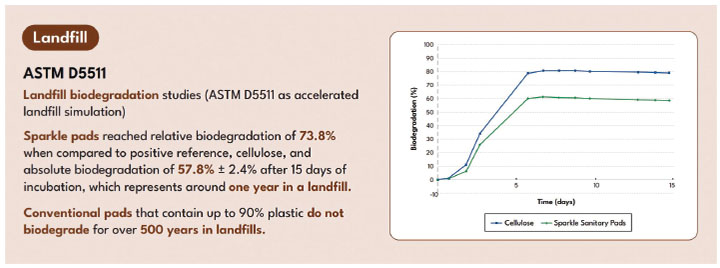

When tested under ASTM D5511 conditions (high-solids, mesophilic, anaerobic conditions that simulate and accelerate the biodegradation process that takes place in a stationary landfill), Sparkle pads reached relative biodegradation of 73.8% when compared to positive reference, cellulose, and absolute biodegradation of 57.8% ± 2.4% after 15 days of incubation, which represents around one year in a landfill.

Sparkle pads are made using biodegradable and compostable ingredients, which makes them commercially compostable according to EN 13242, which means that they are capable of breaking down into organic matter in around four to six months under industrial composting conditions and going back to nature without leaving any toxic residue.

Made with a cellulose-based top sheet, cellulose-based absorbent core, home compostable back film, and wrapper, Sparkle pads can also break down into organic matter and return to the soil when composted in a backyard home compost bin.

When considering the consumer, the problem with plastic is that it’s not breathable, which can create a sweaty and humid environment near your most intimate areas. In fact, perforated polyethylene (PE), also known as “Dry Net,” makes the conventional pad last longer; due to this, you may not feel the need to change your pad as frequently as you should, which can unhygienically promote the growth of unwanted bacteria. In addition, artificial fragrances added to conventional pads can make your sensitive skin feel itchy and uncomfortable.

Sparkle pads are made using a porous network of sustainable and renewable cellulose fibers and do not contain harsh chemicals, artificial fragrances, or dyes.

IFJ: Tell us about your partnership with Hetal Virani in product development?

Virani: Sparkle’s co-founder, Hetal Virani, and I have known each other since we were five years old. We met in kindergarten, went to the same school, and were in the same class until grade 9. We have seen each other grow up and go through many ups and downs in life.

When we decided to start Sparkle, we found something we were both passionate about. With over 10 years of experience, Hetal is responsible for day-to-day planning, implementation, and the management of all financial and operational-related activities of the company. Her passion for promoting equal opportunities for all, and expertise as a chartered accountant and cost accountant allows us to manufacture superior-quality Sparkle products while keeping the overhead costs as low as possible.

IFJ: How much of the pad is biodegradable and how did you test it as such?

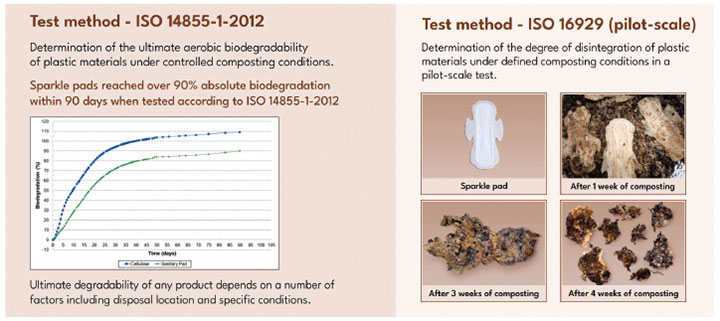

Virani: The biodegradability and compostability of Sparkle pads are tested according to ISO 14855 (determination of the ultimate aerobic biodegradability of plastic materials under controlled composting conditions). According to the standard, the test sample must reach 90% biodegradation in 180 days to pass the test. Sparkle pads reached 90% biodegradation in less than 90 days.

The physical disintegration of Sparkle pads in compost is tested according to ISO 16929 (determination of the degree of disintegration of plastic material under defined composting conditions in a pilot-scale test). According to the standard, 90% of test material should disintegrate and break down into pieces smaller than 2 mm in size after a 12-week period. Sparkle pads reached a disintegration percentage of 100% in less than eight weeks.

IFJ: What is your research and development center currently working on?

Virani: When we were designing our product, we wanted to focus on developing innovative ingredients that could be used to make different layers of a sanitary pad from both a sustainability as well as an end-of-life point of view, while ensuring that we did not compromise on the overall product performance.

At our R&D center (https://sparkle.life/pages/innovations), we are conducting groundbreaking research in several areas.

We are working on utilizing a number of different renewable resources that can also biodegrade without leaving any microplastics or toxic residue behind. We are focusing on utilizing natural cellulosic fibers such as jute, banana fiber, hemp, etc. that can offer a sustainable alternative to conventional, synthetic, and non-biodegradable fibers.

Besides focusing our efforts on up-cycling banana fiber which is used in many of our products, we are also studying several other non-wood, agro-based materials such as bagasse fibers (sugar cane fiber that is a by-product of sugar production) which can be a truly circular alternative source of fiber for absorbent hygiene products.

Our Biopolymers Department focuses on developing sustainable and biodegradable superabsorbent hydrogels using various naturally-occurring polymers such as cellulose and starch, which can provide a sustainable alternative to conventional, synthetic, and non-biodegradable superabsorbent polymers such as sodium polyacrylate.

At our Bioplastics Department, we are conducting research on the compounding of biodegradable and compostable granules suitable for film extrusion, which can provide a sustainable alternative for the back film of a sanitary pad.

As we grow, we are also aiming to establish a more cost-effective and fully vertically-integrated supply chain that can not only allow us to manufacture high-quality sustainable raw materials that go into making our finished products, but also help us reduce our dependence on a highly-volatile supply chain and periodic price fluctuations.

IFJ: Tell us about your manufacturing plant.

Virani: Equipped with a fully automatic Italian production line, Sparkle’s 50,000-square-foot manufacturing facility can produce over one million pads per day, making our company India’s largest manufacturer of sustainable sanitary pads.

We follow strict hygiene and manufacturing process controls at every step of our production process. As a result, our production area has epoxy flooring and central air conditioning with positive pressure to maintain unparalleled quality. It is U.S. FDA registered, as well as ISO 13485, ISO 9001, ISO 14001, and ISO 45001 certified.

With hand sanitizer installed at every entry point, compulsory hair net, uniform, and safety shoes, all our technicians, engineers, and operators also follow strict hygiene controls. Our dust-free production area is equipped with an advanced heating, ventilation, and air conditioning (HVAC) system.

To ensure that our products meet the highest-quality standards consistently, we have implemented a rigorous internal quality management system. During every production run, we conduct an on-line quality inspection on the production floor as well as periodic samples testing of in-depth product quality analysis in our quality assurance lab.

We carefully document all performance parameters such as absorbency, rewet, and adhesive strength with individual batch codes. Our standardized operating procedures allow us to effectively identify any manufacturing defects or errors so that we can quickly take corrective actions.

IFJ: Tell us about the GreenCycle Pilot Project.

Virani: We launched the GreenCycle program to ensure that our plant-based products could go back to nature in a sustainable way instead of ending up in landfills or incinerators.

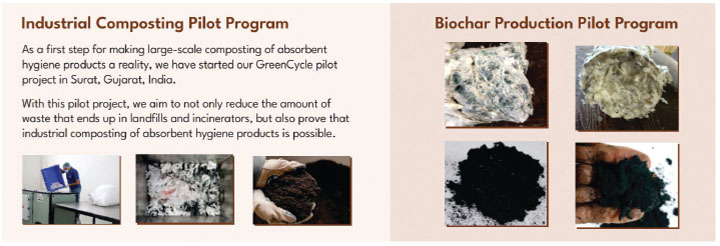

We have explored two very different paths for the sustainable disposal of our products – the first one is establishing decentralized industrial composting units, and the second one is setting up decentralized biochar production units.

As a first step for making the large-scale composting of absorbent hygiene products a reality, we have started our GreenCycle pilot project in Surat, Gujarat, India. With this pilot project, we aim to not only reduce the amount of waste that ends up in landfills, but also prove that industrial composting of absorbent hygiene products is possible.

Once a month, we collected used sanitary pads and transported them to our industrial composting unit, picked up from 100 participating menstruators. At our pilot plant, we use in-vessel hot composting machines that optimize composting conditions such as temperature, turning aeration, etc. to allow microorganisms to thrive and accelerate the natural process of decomposition.

As another alternative to composting, we have also successfully converted our plant-based sanitary pads into biochar, where we heat the material at high temperatures, with little to no oxygen, in a process called pyrolysis. This thermo-chemically transforms the biomass into a stable charcoal-like residue in just a few hours.

This biochar is highly porous and provides ideal conditions for microorganisms to thrive. It can be used as a soil amendment, it increases the water-holding capacity of the soil, it reduces the need for fertilizer, and it also captures carbon dioxide from the atmosphere.

We are working on collaborating with many different organizations that provide reverse logistics services as well as composting services in different geographic regions to close the loop.

Once the decentralized infrastructure of local reverse logistics partners and nearby composting units is established, we aim to utilize this network to compost all of our future products such as baby diapers, incontinence pads, maternity pads, adult diapers, etc.

The hygiene industry is massive and so are the challenges we need to address. We can also look

at these challenges as opportunities.

IFJ: How has the product line been embraced by consumers?

Virani: We have been getting overwhelmingly positive responses from our customers, and we are extremely grateful to them for always supporting our endeavors and products.

Sparkle products are currently available in India through almost all major online channels. In India, through online D2C channels, we are growing with double-digit month-over-month growth.

With regard to offline retail stores, Sparkle pads are available at over 100 stores across 10 states. By 2023 Q3, we plan to be available in over 1,000 stores across India.

Besides India, we have exported our products to Australia, Europe, and Vietnam, and we are entering the U.S. market in March 2023.

IFJ: What advice would you give other innovators who are working to create something new in the hygiene industry?

Virani: The hygiene industry is massive and so are the challenges we need to address. However, we can also look at these challenges as opportunities.

There are multiple challenges present at different stages of the supply chain, for example, developing sustainable raw materials that are more affordable, optimizing product performance by focusing on product design, or developing solutions that focus on end-of-life scenarios so that the products can be disposed of sustainably.

Today’s health-conscious and eco-conscious consumer is willing to go the extra mile to make sustainable choices and to avoid products that contribute to plastic pollution. However, in addition to developing and offering a sustainable product, it is equally important to educate customers about how their choices are beneficial for the environment in the long run so that they can make informed purchasing decisions.

Once customers see your core values and recognize the genuine efforts being made by your brand towards making the world a better place, I feel that they would proudly become your brand ambassadors and help you spread the word.

Another important message I would like to share is to be as transparent and authentic as you can be, and to stay away from “greenwashing.” If your product is not 100% biobased, just say it is only 70% or 80% biobased, or whatever % biobased content you get from an independent third-party lab. Your customer will appreciate your transparency more than you falsely claiming that your product is 100% of something.

IFJ: Is there anything else you want people to know about your journey?

Virani: As a male co-founder selling period products, I have come across many instances that have allowed me to learn and grow as a human being and see social and cultural issues with a lot more clarity, ones that I didn’t know existed before I started the Sparkle journey. I have personally experienced a number of incidents that have made me realize just how much stigma is still there surrounding period products and menstruation in general, especially if a male individual is speaking about these topics.

When I’ve been passionately talking about our innovative plant-based products, I have been told, “No vagina, no opinion. How can you tell me what I should use and should not use if you don’t even know what it is like to get periods?”

There was a potential investor who told me, “If you were a woman, pitching your idea about your revolutionary period products, I would be throwing my money at you.”

At the end of the day, we’re after all trying to create a product that is beneficial for both the environment and for consumers – these kind of comments hit you hard, and of course, it hurts to hear things like this, especially when you’re invested in trying to make a difference for menstruators across the world.

Also, these types of instances reflect the current reality of our society and show how much work we all need to do to break the stigma surrounding menstruation as getting a period is a normal bodily function that is as natural as sleeping, eating, or breathing. Ultimately, we need everyone to come together and collectively work towards solving these multi-dimensional issues.

You can see Sparkle pads in production at www.youtube.com/@SparkleLifeOfficial.