Ph.D. Graduate

North Carolina State University

Fiber & Polymer Science

Research Group:

The Nonwovens Institute (NWI)

Professor/Advisor: Behnam Pourdeyhimi, Ph.D.

Hamid Ebrahimi recently graduated with a Ph.D. in Fiber and Polymer Science from North Carolina State University where he studied polylactic acid (PLA) structure-process-property relationships with other biodegradable polymers. His research was conducted through the Nonwovens Institute (NWI). The NWI serves as a bridge between industry and academia, where students can get the best of both worlds. NWI’s R&D facilities are unique and offer capabilities at the lab scale, as well as pilot scale. NWI supports 40+ Ph.D. and master’s degree students, and over its lifespan has graduated 330+ engineers and scientists who are working in different industries across the globe.

Dr. Ebrahimi’s interest in sustainable polymers began in his senior year when he started researching PLA. He continued his master’s degree later focused on enhancing PLA’s melt strength using chain extension via reactive extrusion. He also investigated the blends of PLA with thermoplastic starch (TPS) and nanoclay to improve toughness and barrier properties of such nanocomposites for the packaging industry.

“Sustainability grew on me gradually and became my mission in life to help move the needle toward a better future for any species living on earth, and PLA was my way in,” said Dr. Ebrahimi.

Research overview

Dr. Ebrahimi, under the direction of Professor Behnam Pourdeyhimi, Ph.D., William A. Klopman Distinguished Professor and Executive Director of NWI, started working on thermal, physical and thermomechanical properties of PLA blend fibers as part of a developmental plan to enhance PLA properties such as strain at break, crystallinity, rate of crystallization and heat deflection temperature (HDT). This project also enjoyed the full support of NatureWorks LLC, the world’s largest manufacturer of PLA. NatureWorks scientists supported Dr. Ebrahimi through his journey, including brainstorming, production, analytical and data analysis.

PLA is one of the bio-based, cost-competitive polymers available in large quantities and is a potential substitute for petroleum-based polymers. However, its brittleness, low HDT, and low crystallization rate has limited its use in applications requiring high heat stability and toughness.

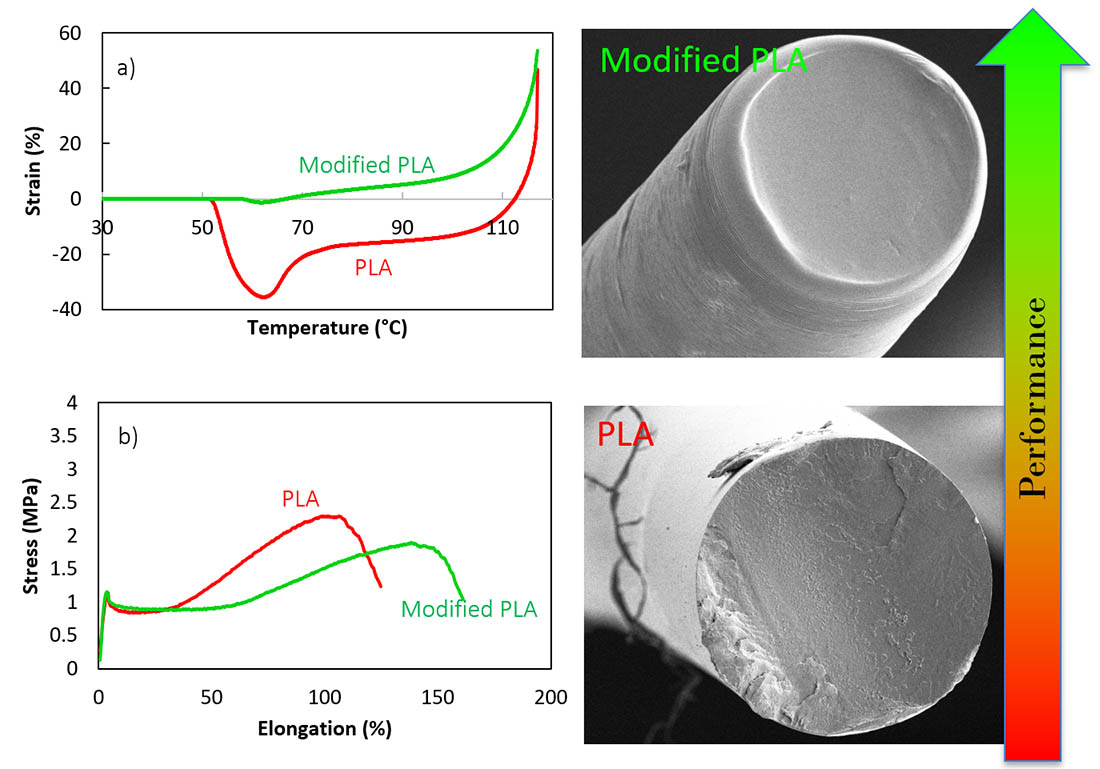

In his research, Dr. Ebrahimi addressed these problems and improved the strain at break, HDT and crystallinity of PLA, around 20%, 25 C, and 30%, respectively. These improved properties unlocked the applications that had previously been out of reach for PLA in fiber and nonwovens.

Higher strain at break potentially offers improved thermal bonding and higher strength, while higher HDT enables PLA to be used in elevated temperatures (e.g., in hot aqueous environments), and higher crystallinity leads to reduced shrinkage, especially for partially oriented fibers, and this offers moldability.

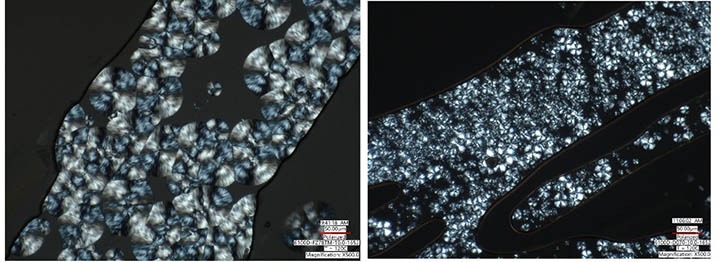

With the COVID-19 pandemic stifling the world in the middle of Dr. Ebrahimi’s doctoral research, the NWI was focused on filter media production to help combat the global facemask shortage. With direction from his principal investigator, Dr. Ebrahimi focused on ways to improve PLA’s electrostatic charging capabilities through nucleation. He found that by increasing the number of crystallites and the rate of nucleation it is possible to produce higher number of smaller crystals, which hold significantly higher electrostatic charges, thus improving filtration efficiency dramatically (Figure 2).

Career goals

Dr. Ebrahimi’s passion has long been sustainability and accelerating the world’s transition toward more sustainable polymers. Recently, he joined a group of scientists at Eastman Chemical Company as an application scientist where he will continue to focus on sustainable options to substitute non-biodegradable, environment-polluting plastics.

“This vision has become my mission in life – every day I wake up to be a better version of myself, and this group of scientists that I am working with has the potential to introduce a solution to our plastic pollution problem, and I am happy I am part of it,” said Dr. Ebrahimi.

Over the next decade, Dr. Ebrahimi wants to see himself in a world that produces less waste and cares more about the end-of-life story of the products it uses. “The amount of waste we produce today is humongous, and we have ruined ecosystems as a result,” said Dr. Ebrahimi. “Soon this will come back to haunt us, if it hasn’t already. We will only be able to solve this problem by introducing circular solutions where every product has a good end-of-life story.”

For details on how to submit yourself or a student you know for consideration as a “Student Spotlight” in IFJ, contact Matt Migliore at mmigliore@inda.media or +1 919.459.3754.