Jordan Tabor is a Ph.D. candidate within the Department of Textile Engineering, Chemistry, and Science at NC State’s Wilson College of Textiles. Her background is in textile engineering, and she is currently pursuing a Ph.D. in Fiber and Polymer Science, as well as a minor in Electrical and Computer Engineering.

5th Year Doctoral Candidate

North Carolina State University Wilson College of Textiles/Textile Engineering, Chemistry, and Science SmARTextiles Laboratory

Professor/Advisor: Tushar K. Ghosh, Ph.D.

Jordan’s general research interests are within the fields of technical textiles, nonwovens, and e-textiles. Her master’s research was funded by The Nonwovens Institute and focused on the structure-property relationships of nonwoven fabrics. Her current doctoral research is funded by the National Science Foundation and focuses on the development of flexible, textile-based sensors for lower limb prosthetics.

Research overview

Jordan’s research is focused on developing flexible, textile-based sensors for wearable applications. More specifically, her aim is to develop sensors that are manufactured using methods that are relevant and transferrable to textile manufacturing.

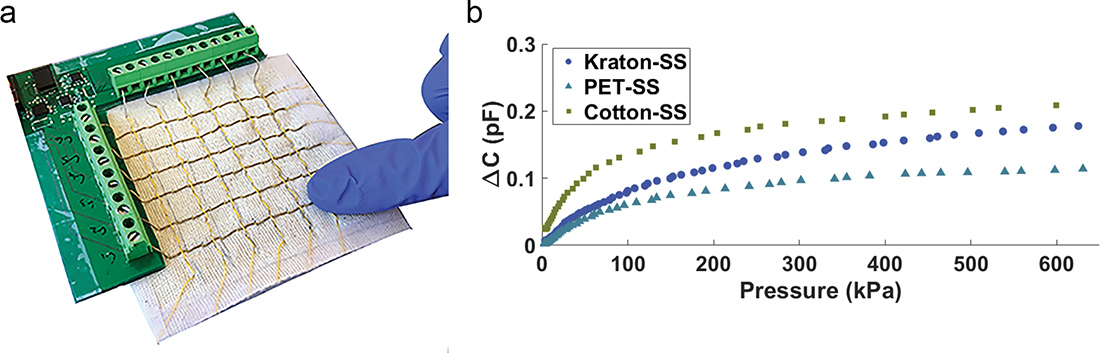

Over the course of her Ph.D. studies, Jordan has explored various techniques of developing textile-based sensors. First was the fabrication of a uniquely shaped fiber using tricomponent melt extrusion. The fibers were transformed into pressure-sensing arrays through the weaving process. Second, she explored sewing conductive yarns perpendicularly such that sensing points were formed at each yarn cross-over point.

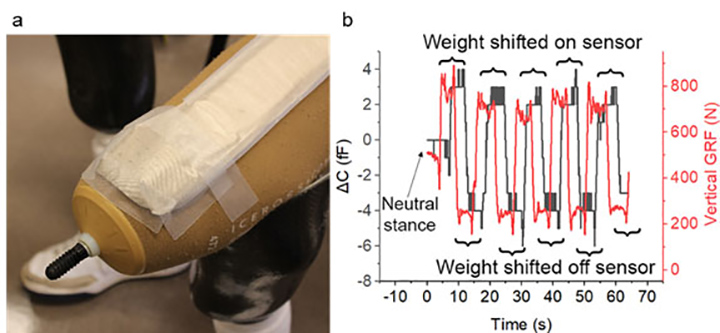

Jordan’s research primarily focuses on developing these sensors for monitoring the environment within lower limb prosthetics. Amputees are often uncomfortable when wearing their prosthetic devices and determining sources of discomfort can be challenging. Many researchers utilize rigid, semiconductor-based sensors to monitor this environment, which can cause further discomfort to amputees. The goal of Jordan’s research is to produce comfortable, large-area, flexible sensors that can be integrated into textile products for amputees to continuously monitor the prosthetic environment. Such devices would provide impactful data to care providers, which could be utilized to improve prosthetics.

The goal of Jordan’s research is to produce comfortable, large-area, flexible sensors that can be integrated into textile products for amputees to continuously monitor the prosthetic environment. Such devices would provide impactful data to care providers, which could be utilized to improve prosthetics.

Beyond the potential positive impact of her research, Jordan finds this topic interesting and compelling because of its inherent interdisciplinary nature. To complete her research, she works closely with electrical and biomedical engineers to achieve project goals. This cross-functional collaboration has provided Jordan opportunities to broaden her perspective and altered the way she approaches research challenges.

The results of Jordan’s research indicate that textile-based sensors can be produced in relatively simple and scalable methods transferrable to the textile industry. Recently published work (https://lnkd.in/g7kHwp4) demonstrates that textile-based sensors can be used within the prosthetic environment to monitor pressure changes without causing additional discomfort to an amputee.

Career goals

In the short-term, Jordan is looking forward to completing her Ph.D. and sharing the remaining results of her dissertation via publications. Some of her most exciting work, which has taken several years of material, process, and electronics R&D, are in their final stages of completion, and Jordan is quite excited to complete this work and share those findings with the scientific community.

After completion of her Ph.D., Jordan plans to join industry as a scientist, researcher or engineer. She is interested in staying within the cutting-edge field of e-textiles, but is also open to new research opportunities.

Longer-term, Jordan would like to take on a technical mentoring role. She is currently teaching a textile-engineering course, which provides a fulfilling opportunity to guide and mentor students. She has also overseen several undergraduate researchers. She enjoys these opportunities to communicate her research knowledge and approaches. Jordan is also interested in promoting female participation in STEM studies and has served as an officer in the organization, Graduate Women in Science.

textiles.ncsu.edu/tecs/research/lab-testing-facilities/smartextiles-laboratory/