Overview of Emerging Biodegradable Polymers, Their Suitability and Commercial Applications In Textiles, and Future Challenges

Over the years, the consumption of single-use plastics has been on the rise due to their attributes of durability, lightweight nature, and cost-effectiveness. Globally, an astonishing 9.2 billion tons of plastic have been manufactured, with annual production reaching 368 million tons in 2019. It is estimated that the annual generation of plastic waste amounts to 34 million tons, with a staggering 93% of this waste ending up in landfills and oceans. The production of synthetic petroleum-based plastics contributes to the growing issue of plastic waste, which in turn has detrimental effects on the environment, including ozone depletion, eco-toxicity, the release of carcinogens, global warming, and eutrophication.1–3

In response to growing environmental concerns about non-biodegradable plastics, bioplastics have emerged as an alternative solution. Biobased polymers, often referred to as bioplastics, represent a class of materials derived from renewable sources such as plants, algae, and microorganisms. Unlike traditional petroleum-based plastics, which are dependent on fossil fuels and contribute to environmental issues, biobased polymers offer a more sustainable and eco-friendlier alternative.

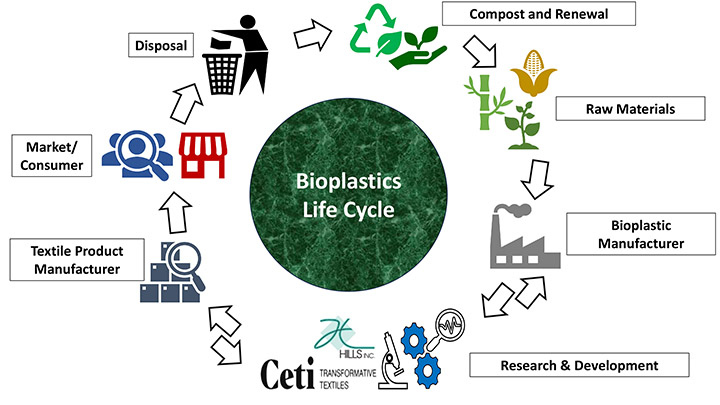

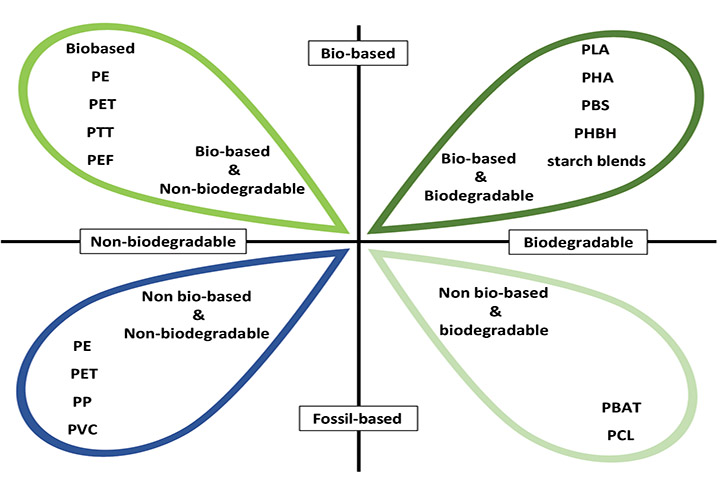

The bioplastic term is commonly used but its definition is still ambiguous. Biobased plastics are fully or partially made from biological resources, rather than fossil raw materials (Figure 1). They are not necessarily biodegradable or compostable. It is important to examine the full lifecycle of biobased plastics, to ensure that they are beneficial to the environment beyond the reduction in the use of fossil resources.

Conversely, a biodegradable plastic undergoes degradation due to the activity of naturally-occurring microorganisms like bacteria, fungi, and algae (ASTM D 6400-99). Furthermore, a plastic that breaks down through biological processes while composting, producing CO2, water, inorganic compounds, leaving behind no visible, distinguishable, or toxic residue. (ASTM D 6400-99).4,5

Presently, the worldwide annual production of 100% biobased polymers stands at approximately two million tonnes, with biodegradable plastics constituting the majority, accounting for two-thirds of this quantity. Anticipated growth in the annual production of biobased and biodegradable polymers is expected in 2023. However, when compared to petroleum-based plastics, the bioplastics market share is projected to remain relatively modest at 2%, with an annual growth rate of 4%. In Europe, the growth rate is notably higher at 10%, primarily driven by forthcoming market regulations and increased consumer demand for sustainable products.

The bioplastic term is commonly used but its definition is still ambiguous. Biobased plastics are fully or partially made from biological resources, rather than fossil raw materials. They are not necessarily biodegradable or compostable.

On a global scale, growth rates could potentially reach 10-20% if bioplastics received similar subsidies and political support as biofuels. Bioplastics and biodegradable plastics are currently finding applications in packaging, food packaging, disposable household items, agricultural films, textiles, and construction. The increasing diversity of applications for biobased polymers promises to yield favorable environmental and economic consequences.2,6,7

Applications for Viable Sustainable Options

Biobased polymers have become increasingly prominent in the textile industry, and this surge in popularity is driven by the pressing need for more sustainable and environmentally-friendly materials. These polymers, notably exemplified by substances like polylactic acid (PLA) and polyhydroxyalkanoates (PHA), and Polybutylene succinate (PBS), are being utilized in a wide spectrum of textile applications. They are at the forefront of a burgeoning eco-conscious textile revolution, offering a range of benefits.

For instance, biobased textiles are finding their way into everyday clothing and apparel, including the likes of casual wear, activewear, and stylish fashion pieces. These textiles are prized for their comfort, breathability, and softness, offering consumers an eco-friendly alternative to conventional fabrics. Their moisture-wicking properties make them ideal for sportswear, ensuring that athletes and outdoor enthusiasts can perform optimally while minimizing their environmental footprint.6

Moreover, biobased textiles are finding their place in workwear and uniforms, providing both comfort and durability. The workwear sector has recognized the potential of these textiles to meet the dual requirements of sustainability and resilience in demanding environments.

Home textiles, such as bed linens and upholstery, are also benefiting from biobased polymers, enhancing both comfort and sustainability for households. Furthermore, eco-friendly accessories, including hats, scarves, and bags, are embracing these textiles, offering consumers stylish and sustainable options.

Beyond fashion and personal use, biobased polymers are making their way into technical textiles, where their unique properties can offer advantages in specialized applications, such as medical textiles, geotextiles, and automotive textiles. The trend toward eco-conscious fashion and textiles is undoubtedly here to stay, with biobased polymers playing a pivotal role in this transformation, contributing to a more sustainable and environmentally conscious future in the textile industry.6,8

Industry Considerations for Biobased Polymers

The incorporation of biobased polymers into industrial practices is a multifaceted endeavor, necessitating a thoughtful consideration of numerous key elements. First and foremost, industries must meticulously evaluate whether the properties of these biobased materials align with the specific functional requirements of their intended applications. Factors such as tensile strength, flexibility, durability, and resistance to various environmental conditions must be scrutinized to ensure that they meet industry standards. Equally important is the cost-effectiveness and the availability of a consistent supply of biobased polymers. While these materials often boast impressive sustainability benefits, they can sometimes come at a higher price point compared to their conventional petroleum-based counterparts. Industries must conduct thorough cost-benefit analyses to determine their economic viability.

Furthermore, it’s vital to assess the availability and accessibility of these materials to maintain production consistency. At the heart of the adoption of biobased polymers lies the paramount consideration of sustainability. Organizations must explore the numerous environmental benefits that these materials offer, such as a significantly reduced carbon footprint and decreased reliance on finite fossil fuel resources. These sustainable attributes contribute to a more eco-conscious approach to production and can align with corporate sustainability goals. Another pivotal factor to consider is regulatory compliance. Industries must adhere to any relevant regulations, standards, and certifications pertaining to biobased materials. These may include labeling requirements, compostability standards, and biodegradability criteria. Maintaining compliance ensures both ethical and legal usage of these materials.

Moreover, the industry must factor in the end-of-life implications of biobased polymers. Understanding what happens to these materials once they have fulfilled their intended purpose is essential. Questions around recyclability, biodegradability, and compostability are of utmost importance. The availability of proper infrastructure and facilities to manage biobased materials in an environmentally responsible manner must also be taken into account.

One primary challenge revolves around the cost of manufacturing biobased polymers, which can be higher compared to traditional petroleum-based materials. Efforts are required to make biobased textiles economically competitive.

Also, building an ethical and reliable supply chain is fundamental for the consistent sourcing of biobased polymers. This involves identifying and collaborating with sustainable and certified suppliers. The integrity of the sustainability message relies on a transparent and responsible supply chain. Another critical consideration is the adaptability of processing equipment and technology. Some biobased polymers may require adjustments or even new technology for effective utilization. Assessing whether current infrastructure is compatible with these materials and making necessary upgrades is integral to a smooth transition. Furthermore, understanding consumer demand and preferences is vital. Industries should gauge market trends and consumer attitudes towards biobased products. An increasing consumer inclination towards sustainable and eco-friendly alternatives can inform decisions on product development and marketing strategies.

Continuous research and development play a central role in the successful integration of biobased polymers. Investments in innovation are essential to improve material properties and cost-effectiveness, expanding the range of applications and enhancing the overall value proposition of these materials. Additionally, industries should consider education and awareness initiatives. Educating employees, partners, and consumers about the benefits and proper use of biobased materials is crucial. Awareness campaigns can contribute to building a positive image and driving acceptance of these sustainable alternatives.

Lastly, it’s essential to recognize that adopting biobased polymers should not be viewed as a short-term trend, but as a long-term commitment to sustainability. Industries should plan for the future and work on strategies for continually reducing the environmental impact of their products. This ongoing commitment is integral to the evolving landscape of sustainable practices and the achievement of lasting, positive environmental change.6,8

Future Challenges and Pathways to Overcome Them

The integration of biobased polymers into the textile industry holds promise as a path toward a more sustainable and environmentally friendly approach. However, this incorporation comes with a set of crucial challenges and considerations that must be addressed for a successful transition. One primary challenge revolves around the cost of manufacturing biobased polymers, which can be higher compared to traditional petroleum-based materials. Efforts are required to make biobased textiles economically competitive. Establishing a dependable and scalable supply chain for biobased polymer feedstocks is of utmost importance, necessitating collaboration between industries and suppliers.

Moreover, biobased polymers may not always match the performance characteristics of conventional synthetic materials, demanding research and development to enhance qualities like strength, durability, and colorfastness. Furthermore, developing recycling infrastructure, especially for biodegradable textiles, is essential, and so are the suitable disposal methods and composting facilities to mitigate environmental concerns. Ensuring compatibility with other materials in textile blends may entail adjustments and upgrades when incorporating biobased polymers into existing textile processes to maintain product quality. Besides, compliance with regulations is crucial for gaining consumer trust and meeting industry standards.

The importance of educating consumers about the advantages and proper care of biobased textiles cannot be overstated for market acceptance. As the demand for biobased materials grows, there is potential competition for renewable resources, which could impact other industries, underscoring the need for sustainable sourcing practices. Addressing technical challenges related to moisture, temperature, and UV sensitivity is critical to ensure the reliability of biobased polymers. The journey to scale up the production of biobased textiles for commercial use involves investments in technology, infrastructure, and research, representing a significant challenge.

Diversifying the range of feedstocks used for biobased materials has the potential to reduce resource competition and enhance sustainability. Convincing consumers and industries of the long-term benefits of biobased textiles and their contribution to sustainability is pivotal for their adoption. While these challenges are substantial, the potential advantages of employing biobased polymers in textiles, such as mitigating environmental impact and reducing reliance on fossil fuels, position them as a valuable avenue for a more sustainable future in the textile industry.

Overcoming these hurdles necessitates collaboration among industries, researchers, and policymakers to drive innovation and establish a more sustainable textile sector. By investing in research and development, optimizing production processes, establishing recycling infrastructure, promoting sustainability, and raising awareness, the textile industry can successfully integrate biobased polymers and contribute to a more sustainable future.6–8

Is a Sustainable Polymer Really Possible?

Attaining a genuinely sustainable polymer base for plastics is a complex but achievable objective. Sustainability in the realm of plastics hinges on a range of strategies and innovations designed to mitigate environmental impact and reduce reliance on finite fossil fuels.

One prominent avenue involves bio-based polymers, which derive their origins from renewable sources like plants and algae. These materials, exemplified by polylactic acid (PLA) and polyhydroxyalkanoates (PHA), have already made significant inroads by exhibiting reduced carbon emissions and a smaller environmental footprint compared to conventional plastics. Their broader adoption and continued improvement hold the potential to contribute significantly to the sustainability of the industry.6,9

Recycling, another cornerstone of this sustainable future, demands increased efficiency and broader implementation. The concept of a closed-loop recycling system, where plastics are collected, processed, and reintroduced into the production cycle in an unbroken continuum, is gaining traction. This not only decreases the demand for new plastic production but also minimizes the pernicious impact of plastic waste on the environment.

The deployment of biodegradable plastics is yet another facet of this multifaceted effort. These plastics are engineered to break down into natural substances when exposed to specific conditions, mitigating the persistence of plastic waste in our ecosystems. Nevertheless, the successful adoption of biodegradable plastics depends significantly on the existence of an infrastructure for proper disposal and composting.

Innovations in materials science hold the promise of delivering plastics with improved properties, extended longevity, and enhanced recyclability. These advancements are achieved through the development of polymer blends, nanocomposites, and other novel materials. By harnessing the power of advanced materials, the industry can create plastics that better meet the demands of sustainability.

However, the shift toward sustainability transcends material innovation. It encompasses the entire lifecycle of plastics, where the principles of a circular economy take center stage. This approach prioritizes the reduction of waste, the reutilization of materials, and the promotion of recycling, all essential steps toward minimizing the environmental impact of plastic production and use.

Simultaneously, the reduction of single-use plastics, exemplified by disposable packaging and utensils, is gaining momentum. Governments and businesses are recognizing the urgency of phasing out or diminishing the use of these items and are either transitioning to alternative materials or advocating the use of reusable options.

This multifaceted approach to plastic sustainability is significantly bolstered by comprehensive life cycle assessments. These assessments provide a holistic understanding of the environmental impact of plastic products, from their initial production to their eventual disposal. Armed with this knowledge, industries can identify areas for improvement and work towards reducing their overall environmental footprint.

Public awareness and education play a pivotal role in the journey toward sustainability. By fostering a widespread understanding of responsible plastic usage, recycling practices, and disposal methods, a more informed and eco-conscious society can help curtail plastic pollution.

Regulations and policies also hold considerable sway in promoting sustainability. Governments have the capacity to enact legislation that encourages the use of sustainable materials, advances recycling initiatives, and discourages environmentally detrimental practices.

While significant strides have been made in the quest for sustainability, challenges remain. These include ensuring that bio-based materials do not compete with food production, addressing the limitations of current recycling technologies, and creating a cohesive global approach to plastic sustainability. Nonetheless, the commitment to reducing the environmental impact of plastics is not merely an aspiration; it is a pressing imperative for the welfare of our planet and for the generations that will inherit it. Therefore, while the journey toward sustainability may be intricate and ongoing, it is a journey well worth embarking upon.10,11

Ongoing efforts

Ultimately, the path toward a truly sustainable polymer base in plastics is a collaborative endeavor. It requires cooperation between industries, research institutions, and environmental organizations, as well as an unwavering commitment to reducing the environmental impact of plastic production and usage.

As previously mentioned, the introduction of biobased polymers into the textile sector holds promise for sustainability but also poses critical challenges. The Centre Européen des Textiles Innovants (CETI) in France is collaborating closely with material manufacturers and fiber technology developers to integrate biobased plastics into textiles. For example, Hills Inc. (USA) has been at the forefront of fiber technology and has established a robust decade-long partnership with CETI. Together, they have engaged in numerous research and development initiatives geared towards bolstering the textile industry.

In anticipation of forthcoming challenges, CETI and Hills are working together to push the limits by introducing bio-derived polymer materials for textile use. CETI possess cutting-edge Hills advanced spinning solutions that can support novel formulations, enabling the integration of innovative functionalities into fibers. Additionally, CETI’s multi-component fiber strategy has proven highly successful in ensuring the required mechanical performance at the yarn level, thereby supporting the successful life cycle of biobased plastics. Figure 2 illustrates the proactive involvement of CETI and Hills in the lifecycle of bioplastics.

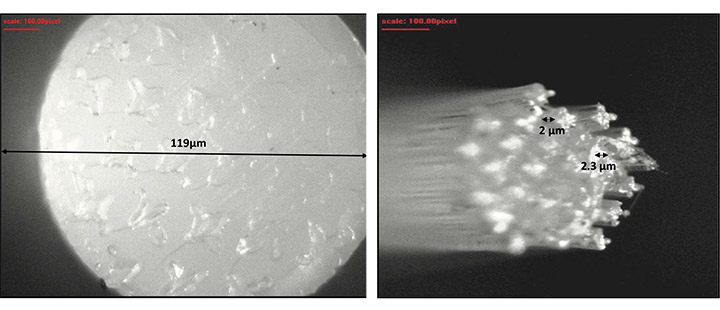

Multicomponent fibers are known to enhance the material’s performance and are commonly used in the development of innovative solutions when various cross-sectional shapes are needed. To develop the high-performance fiber, CETI and Hills are currently developing an innovative approach (Figure 3) using a bi-component yarn development configuration.

References:

- Wu A, March L, Zheng X, Huang J, Wang X, Zhao J, et al. Production, use, and fate of all plastics ever made [Internet]. Vol. 388, Nature. 2020. p. 1–14. Available from: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.science.org/doi/pdf/10.1126/sciadv.1700782

- Ellen MacArthur Foundation and World Economic Forum. The New Plastics Economy: Rethinking the future of plastics. Ellen MacArthur Found. 2016;(January):120.

- European Commission. A European Strategy for Plastics. Eur Com [Internet]. 2018;(July):24. Available from: http://ec.europa.eu/environment/circular-economy/pdf/plastics-strategy-brochure.pdf%0Ahttp://ec.europa.eu/environment/circular-economy/index_en.htm

- Folino A, Pangallo D, Calabrò PS. Assessing bioplastics biodegradability by standard and research methods: Current trends and open issues. J Environ Chem Eng. 2023;11(2).

- Report T. EPIC 2000-Biodegradable polymers- A review.pdf.:1–11.

- Di Bartolo A, Infurna G, Dintcheva NT. A review of bioplastics and their adoption in the circular economy. Polymers (Basel). 2021;13(8).

- Li L, Huang W, Wang B, Wei W, Gu Q, Chen P. Properties and structure of polylactide/poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PLA/PHBV) blend fibers. Polymer (Guildf). 2015 Jun 26;68:183–94.

- Hann S, Scholes R, Briedis R, Kirkevaag K. Biobased and Biodegradable Plastics: An Assessment of the Value Chain for Bio-Based and Biodegradable Plastics in Norway. Eunomia Nor Environ Agency. 2018;

- Qi X, Ren Y, Wang X. New advances in the biodegradation of Poly(lactic) acid. Int Biodeterior Biodegradation. 2017 Feb 1;117:215–23.

- Odegard I, Nusselder S, Roos Lindgreen E, Bergsma G, de Graaff L. Biobased Plastics in a Circular Economy Policy – Policy suggestions for biobased and biobased biodegradable plastics. Ce Delft. 2017;136.

- Meereboer KW, Misra M, Mohanty AK. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem. 2020;22(17):5519–58.