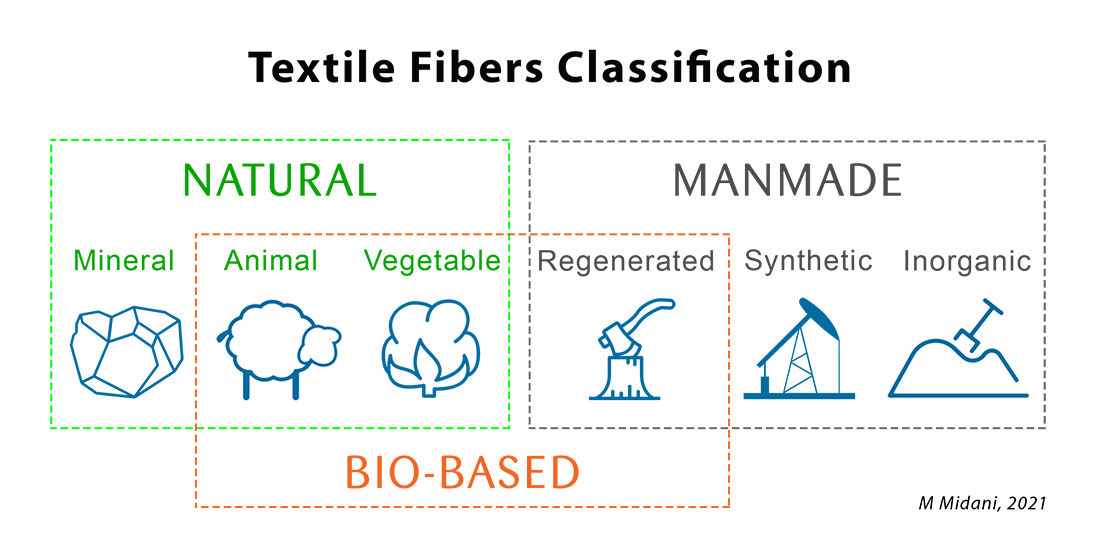

A biofiber is a fiber derived of biological origin, whether produced naturally or via a regenerated process. The classification can be broken down further as a collection of cells in which the diameter is negligible in comparison with the length, which is consistent with the definition of a manmade polymer.

A polymer is a larger molecule that is built up by a repletion of small, simple chemical units. The prevailing difference between a biofiber and a non-biofiber is the origination source. Technology is blurring this a bit, as we are now able to produce fibers with a chemical structure that is identical to those found in nature through chemical and non-chemical modification.

The promise of biofibers is the preservation of natural resources with a focus on the utilization of renewable raw materials that, in many cases, are biodegradable at end of life.

Unlike chemically modified fibers, biofibers abound in nature in fibrous materials, especially those in the cellulosic category. Hemp is one of the oldest, if not the oldest, cultivated fiber plants and is currently finding renewed interest holistically, including all parts of the plant’s fibrous material, as well as its seeds and flowers.

The promise of biofibers

The promise of biofibers is the preservation of natural resources with a focus on the utilization of renewable raw materials that, in many cases, are biodegradable at end of life. Biodegradable polymers have offered scientists a possible solution to waste‐disposal problems associated with traditional petroleum‐derived plastics that are difficult to recycle and/or repurpose.

The continuing challenge remains in finding applications that would consume sufficiently large quantities of these materials to enable price reduction and allow biofibers to compete economically in the market.

Biofibers typically have a preferred lifecycle from an environmental and sustainability perspective when compared to polymer fibers. This includes sourcing, manufacturing, use and end of life.

Bonus ’Tech Talk’ Video

Learn More @ inda.org/education!

However, there are many key performance indicators in each aspect of the lifecycle. Two of the most often considered are greenhouse gas emissions in production and end-of-life. Resource usage is another important factor to consider, particularly when evaluating biofiber production. Biofibers typically require a lot of water for both irrigation and process. In terms of environmental biodegradability, biofibers typically break down more quickly than polymerics (a positive), but when we look at cost, they do not typically have an advantage over polymeric fibers, due to the aforementioned issue of scale.

Regulatory factors

The evolving regulatory landscape for fibers, led by the European Union’s Single Use Plastics Directive (SUPD), as well as other regulatory efforts worldwide, aim to reduce plastics in the environment, which should positively affect the biofiber market. As pressure mounts on plastic materials with extended producer responsibilities, reductions and outright bans looming, demand for biofibers figures to grow.

However, if we look at viscose, for example, the SUPD defines natural polymers as “not chemically modified,” where the ingoing and final polymer have the same chemical structure regardless of any modifications that might have happened during the production process.

The latest draft of the SUPD guidelines seems to contradict this earlier definition. It argues that forming or breaking of covalent bonds of the polymer during the manufacturing process changes the final polymer structure and therefore is a determining factor with respect to chemical modification, even if the natural polymer in the final product remains cellulose. Currently, there is no scientific evidence showing how this can cause a material with the same final chemical structure to have a different environmental impact than the initial material. But the debate continues, and the final conclusion in this area may mean that some “biofibers” will get tripped up in the effort to regulate plastics in the environment. We shall see …

Technological evolution

Although there are many natural sources for biofibers, the most prolific biopolymer that is made into biofibers in the market today is polylactic acid (PLA). This biotechnology is synthesized from a bio-derived monomer in the form of polactides. PLA’s success can be attributed to its availability, cost and ease of processability.

Other promising technologies are those that can be extracted from microorganisms. PolyHyroxyAlkanoates (PHA) and Polyhydroxbuyrateco-hydroxyvalerate (PHBV) are examples. Currently, there are a wide variety of PHAs in the marketplace, and there are several that have promise for fibers. PHBV monofilament fibers have shown to be remarkably biocompatible and have relatively high degradability over time with human tissue. These fibers have great potential in medical applications, as they could, for example, reduce the size of a scar and degrade into non-toxic, and in some instances, beneficial nutrients to aid in the healing process.

The future

Biofibers will continue to gain traction in the years to come as more legislation on polymeric fibers are enacted. The biofiber market is growing, and key players are those in the filtration industry. Cellulose fibers in automotive filtration applications, for example, are significant. Fibers are also being utilized as composite fillers with non-bio polymers. These compounds are lower cost and lighter weight than traditional mineral-reinforced products.

Nature’s basic operating principle means it uses only the energy it needs; it recycles everything; and it thrives on diversity. Adhering to these basic principles will serve the fiber industry now, and in the years to come.

Have a different perspective on or definition of biofibers? Please reach out and let me know your thoughts. There are certainly some gray areas, as fiber technology continues to evolve.

As INDA’s director of education and technical affairs, Chris presents regular training related to nonwovens and filter media from INDA headquarters in Cary, NC. For more information about upcoming training opportunities, visit inda.org/education.

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).